- Thread starter

- #381

I received the package that should have been my thrust washers but they sent me the wrong things. They sent me oil seals by mistake

Did some more work on the forks.

Here I welded the top part of the bottom plate, drilled the holes for the pivot point and cut the down tubes to the right length. (am I saying that correctly are they called down tubes?)

First pass with the cutoff wheel making the rockers

Cut in half now need to weld in the 1 side

welded the side plate on. 1/4" thick. Notice the discoloration. They both warped when I welded them. I had to heat them and flatten them back out again

Side View

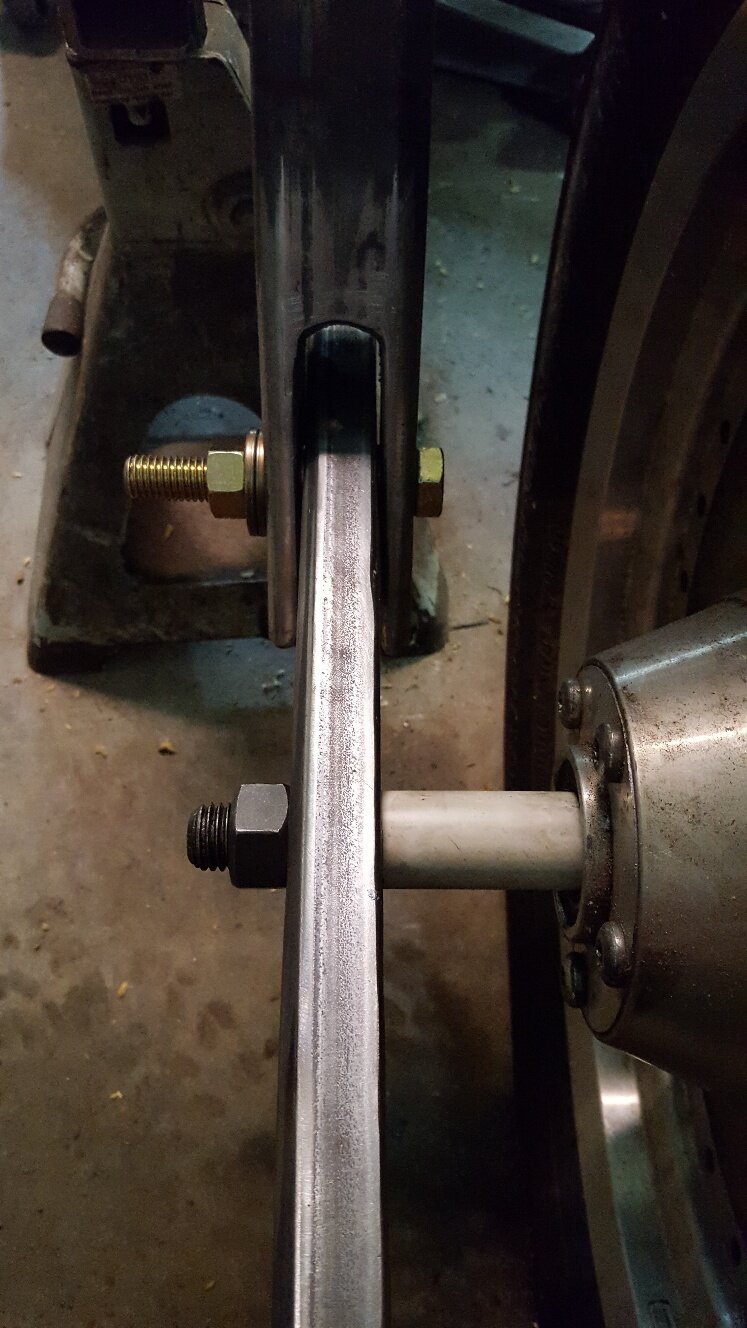

Need to drill the hols for the pivot point and the axle and weld in the inserts.

To Hot to work out there anymore today.

Did some more work on the forks.

Here I welded the top part of the bottom plate, drilled the holes for the pivot point and cut the down tubes to the right length. (am I saying that correctly are they called down tubes?)

First pass with the cutoff wheel making the rockers

Cut in half now need to weld in the 1 side

welded the side plate on. 1/4" thick. Notice the discoloration. They both warped when I welded them. I had to heat them and flatten them back out again

Side View

Need to drill the hols for the pivot point and the axle and weld in the inserts.

To Hot to work out there anymore today.