Jack Klarich

18000+ Posts

Have a look here if your TBW is acting up and you have a check engine light on with stored codes with part numbers

BW Issues Explained by HD Service Bulletin TT418A a MUST READ

This is some must read info for everyone that has had issues with the TBW. This is a service bulletin issued by HD on 1/7/2011 it is bulletin # TT418A: DTC's P2135 & P2101 Theory & Diagnostics. I am going to condense this some but I also believe from my past experiences with my TBW that this also would include the P1510 code.

TT418A service bulletin applies to 2008-Later Touring, Police & Trike Models

Symptoms: Driveability or Performance Concerns; Abnormal or Erratic Mechanical Operation; Intermittent or Erratic Electrical Operation.

Note: Throttle Position Sensor (TPS) circuit DTC's P0120, P0220, P0122, P0123, P0222 and P223 should take diagnostic priority over a P2135 code. If any of these TPS codes exist concurrently with the P2135, they should be investigated first using the diagnostic manual.

The TCA has two potentiometers (designated as TPS1 & TPS2) and a electric DC motor for controlling the actuation of the throttle. The two TPS sensors work opposite of each other. As the throttle plate opens , TPS1 voltage ranges from 0.0-5.0 Volts, while TPS2 voltage ranges from 5.0-0.0 volts. The sum of the two TPS voltages should always measure approximately 5.0 volts. These wire are: TPS1, pin # 37 (BN/V wire) of the ECM, and TPS2 pin #36 (BN/R wire) of the ECM

The TPS1 and TPS2 sensors should never add to more than 5.13 Volts Direct Current (VDC) or less than 4.87 VDC . A sum of voltages out of this range should register a current P2135 code.

Troubleshooting:

It is believed that FRETTING CORROSION is a major contributor of this code. A poor connection at the Throttle Control Actuator (TCA) can affect the sensor voltages reported to the ECM and this will set this DTC. As you can see from the General Information section, the sensor voltage only need to be altered by 0.13 VDC to possibly set the code.

The most common vehicles to have these symptoms are those with more than 8,000 miles (12875 Kilometers) or 103 cubic inch and larger engines. Vibration is believed to contribute to the FRETTING CONDITION.

Repair Procedure:

1. While monitoring the TPS1 and TPS2 voltages on Digital Technician 2 (DT 2), wiggle the TCA [211] and the ECM [78] connectors.

2. If the voltage changes while wiggling the ECM connector , replace the affected ECM terminals (part # 72605-08). These wires are: TPS1, pin #37 brown/violet wire of the ECM, and TPS2, pin #36 brown/red wire of the ECM.

3. If no voltage change is noted while moving the ECM connector , the connection issue could be in the TCA. Replace all socket terminals with NEW terminals (part # 72663-11, used in current production) at the TCA connector[211B].

4. BEFORE CONNECTING the TCA CONNECTOR, clean the male TCA pin terminals with a swab and alcohol, and ASSEMBLE WITH DIELECTRIC GREASE.

DTC P2101

General Information: The TCA contains two potentiometers (designated as TPS1 & TPS2) and a electric DC motor for controlling a actuation of the throttle. TPS1 & TPS2 are mounted in the TCA. They are connected to the keyed shaft of the throttle plate and used to communicate the throttle plate position.

Each TPS supplies input to the ECM in response to the position of the throttle plate. The ECM activates the motor in the TCA to move the throttle plate, based on signals from the Twist Grip Sensor (TGS). When the ECM send voltage modulations to pins 2 & 3 0f the TCA to move the throttle motor, it checks fo subsequent TPS1 and TPS2 voltage changes. If it does not sense TPS changes it will set this code.

Troubleshooting: First verify that the throttle plate moves freely when engine is not running. If it does not the TCA needs to be replaced.

Poor ECM connections seem to be the most likely cause. Be aware that this issue may be aggravated by the seat pan making contact with the ECM connector. In most cases, this is caused by the installation of an aftermarket seat.

A poor connection at ECM pins #29 & 30 could cause an interruption in voltage to the throttle motor and set this code. Similarly the ECM uses voltage from pin #52 yellow/green wire to supply power used at pins #29 & 30 and could cause the same symptoms.

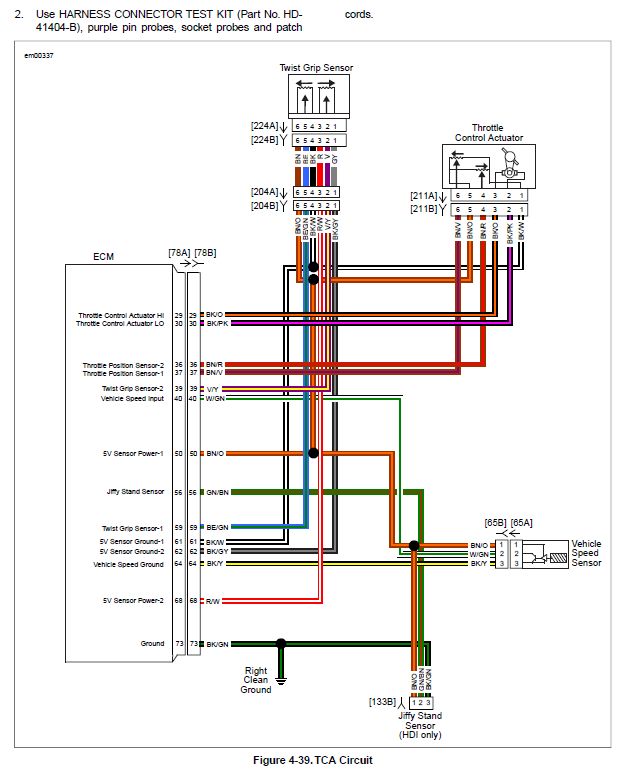

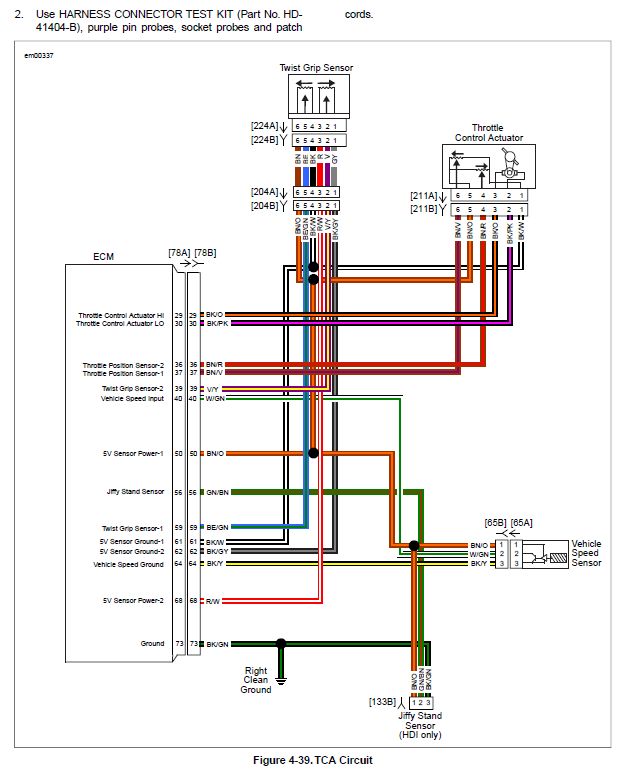

Here is a diagram of the connections that need to be cleaned and lubed

BW Issues Explained by HD Service Bulletin TT418A a MUST READ

This is some must read info for everyone that has had issues with the TBW. This is a service bulletin issued by HD on 1/7/2011 it is bulletin # TT418A: DTC's P2135 & P2101 Theory & Diagnostics. I am going to condense this some but I also believe from my past experiences with my TBW that this also would include the P1510 code.

TT418A service bulletin applies to 2008-Later Touring, Police & Trike Models

Symptoms: Driveability or Performance Concerns; Abnormal or Erratic Mechanical Operation; Intermittent or Erratic Electrical Operation.

Note: Throttle Position Sensor (TPS) circuit DTC's P0120, P0220, P0122, P0123, P0222 and P223 should take diagnostic priority over a P2135 code. If any of these TPS codes exist concurrently with the P2135, they should be investigated first using the diagnostic manual.

The TCA has two potentiometers (designated as TPS1 & TPS2) and a electric DC motor for controlling the actuation of the throttle. The two TPS sensors work opposite of each other. As the throttle plate opens , TPS1 voltage ranges from 0.0-5.0 Volts, while TPS2 voltage ranges from 5.0-0.0 volts. The sum of the two TPS voltages should always measure approximately 5.0 volts. These wire are: TPS1, pin # 37 (BN/V wire) of the ECM, and TPS2 pin #36 (BN/R wire) of the ECM

The TPS1 and TPS2 sensors should never add to more than 5.13 Volts Direct Current (VDC) or less than 4.87 VDC . A sum of voltages out of this range should register a current P2135 code.

Troubleshooting:

It is believed that FRETTING CORROSION is a major contributor of this code. A poor connection at the Throttle Control Actuator (TCA) can affect the sensor voltages reported to the ECM and this will set this DTC. As you can see from the General Information section, the sensor voltage only need to be altered by 0.13 VDC to possibly set the code.

The most common vehicles to have these symptoms are those with more than 8,000 miles (12875 Kilometers) or 103 cubic inch and larger engines. Vibration is believed to contribute to the FRETTING CONDITION.

Repair Procedure:

1. While monitoring the TPS1 and TPS2 voltages on Digital Technician 2 (DT 2), wiggle the TCA [211] and the ECM [78] connectors.

2. If the voltage changes while wiggling the ECM connector , replace the affected ECM terminals (part # 72605-08). These wires are: TPS1, pin #37 brown/violet wire of the ECM, and TPS2, pin #36 brown/red wire of the ECM.

3. If no voltage change is noted while moving the ECM connector , the connection issue could be in the TCA. Replace all socket terminals with NEW terminals (part # 72663-11, used in current production) at the TCA connector[211B].

4. BEFORE CONNECTING the TCA CONNECTOR, clean the male TCA pin terminals with a swab and alcohol, and ASSEMBLE WITH DIELECTRIC GREASE.

DTC P2101

General Information: The TCA contains two potentiometers (designated as TPS1 & TPS2) and a electric DC motor for controlling a actuation of the throttle. TPS1 & TPS2 are mounted in the TCA. They are connected to the keyed shaft of the throttle plate and used to communicate the throttle plate position.

Each TPS supplies input to the ECM in response to the position of the throttle plate. The ECM activates the motor in the TCA to move the throttle plate, based on signals from the Twist Grip Sensor (TGS). When the ECM send voltage modulations to pins 2 & 3 0f the TCA to move the throttle motor, it checks fo subsequent TPS1 and TPS2 voltage changes. If it does not sense TPS changes it will set this code.

Troubleshooting: First verify that the throttle plate moves freely when engine is not running. If it does not the TCA needs to be replaced.

Poor ECM connections seem to be the most likely cause. Be aware that this issue may be aggravated by the seat pan making contact with the ECM connector. In most cases, this is caused by the installation of an aftermarket seat.

A poor connection at ECM pins #29 & 30 could cause an interruption in voltage to the throttle motor and set this code. Similarly the ECM uses voltage from pin #52 yellow/green wire to supply power used at pins #29 & 30 and could cause the same symptoms.

Here is a diagram of the connections that need to be cleaned and lubed