- Thread starter

- #161

Getting upset and pissed off does me NO good in life, seems I drove my self into a rant and a seizure at 5:50am yesterday morning, so I am a bit lost at the moment and slowly getting my thoughts together....Normally I do something stupid like use cleaning chemical sprays, or a bathroom cleaning product, none I can use with out a episode.

That maybe the trick to getting the job done Larry, I do hope I do not have to go that far to get the work done, but I guess I will do what it takes if at all possible.

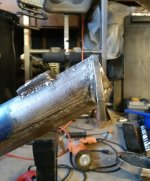

Rex, not even sure what they did to look the forks over, I do remember one pointing out that the rockers are bent and they do not know how to straighten them. I simply asked why I could not make a set of new rocker's, especially if I am going to convert this set of springer forks into a set of Leading arm forks, doing this will allow me to increase tire size and get a little lift and with the leading arm design I can limit the trail in the forks to a few inch's.

Yes, it works out best for me if I can get things done here at the house, but if I have to load it up and run around looking for the one to do the job, than I guess that is what I will do.

That maybe the trick to getting the job done Larry, I do hope I do not have to go that far to get the work done, but I guess I will do what it takes if at all possible.

Rex, not even sure what they did to look the forks over, I do remember one pointing out that the rockers are bent and they do not know how to straighten them. I simply asked why I could not make a set of new rocker's, especially if I am going to convert this set of springer forks into a set of Leading arm forks, doing this will allow me to increase tire size and get a little lift and with the leading arm design I can limit the trail in the forks to a few inch's.

Yes, it works out best for me if I can get things done here at the house, but if I have to load it up and run around looking for the one to do the job, than I guess that is what I will do.