pwhoever

350+ Posts

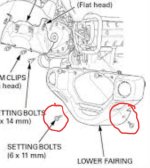

On my 07, there are 2 button head screws on each side of the lower cowl that need to be removed along with 2 more and plastic rivets above to take off that lower cowl. They need to be removed by using a 5mm Allen wrench. My problem is that these 2 side screws are well hidden by the front of the floorboards on my CSC conversion. And it's a bit difficult maneuvering an Allen wrench in there to do this. The "easy" solution is to remove the floorboards to access the screws but this is far from easy. I recently saw an interesting solution on a Hannigan trike where the owner drilled 1" holes on floorboards for access and then uses a plastic plug to cover the hole. To remove those lower cowl screws, pop off the plastic plugs and use a long Allen head wrench. I took a look at the CSC floorboards to see if this was an option but because of the lower turn signal lights on floorboards and the angles there, it won't work.

I needed to remove the lower cowl because it was time to flush and bleed the clutch and access to the bleeder is behind there. And I also needed to service my right side fog light where a minor deerstrike broke the lens. How I didn't get more damage, I really don't know but the broken lens was all I could see. I was able to get those cowl screws off but not without doing some advanced acrobatic twisting to get in there along with working by feel. I'm not sure if I will be able to get those screws back in without removing or at least undoing some of the front mounts on the floorboards.

But getting to my question, has anyone come up with a solution to make reaching those screws easier? I'm wondering if there might be pop rivets that could easily be removed to replace the screws. Or what would be the downside of just leaving those off? My first thought is that I might get some rattling going on. But I'm not to worried about it coming loose because there are 4 more fasteners above and it also tucks in pretty good between the CSC floorboards and it would be very hard for it to work it's way loose on the bottom.

I needed to remove the lower cowl because it was time to flush and bleed the clutch and access to the bleeder is behind there. And I also needed to service my right side fog light where a minor deerstrike broke the lens. How I didn't get more damage, I really don't know but the broken lens was all I could see. I was able to get those cowl screws off but not without doing some advanced acrobatic twisting to get in there along with working by feel. I'm not sure if I will be able to get those screws back in without removing or at least undoing some of the front mounts on the floorboards.

But getting to my question, has anyone come up with a solution to make reaching those screws easier? I'm wondering if there might be pop rivets that could easily be removed to replace the screws. Or what would be the downside of just leaving those off? My first thought is that I might get some rattling going on. But I'm not to worried about it coming loose because there are 4 more fasteners above and it also tucks in pretty good between the CSC floorboards and it would be very hard for it to work it's way loose on the bottom.