grandpanystrom61

New member

Okay I have spent time doing google and searching ebay and amazon sites, even Pacific Custom trike and few other sites.

I did not find what I needed for the upper shock mount bracket. Than I remember my notes and what I was going to do originally. Not something I care to do now because I forgot about SS steal bending or twisting some when welded. I feel I should have done welding first than the machine work so all was good if possible.

So I want mounting brackets that clamp on to the fork tube. Found some choices, but none exactly what I needed or decided I wanted.

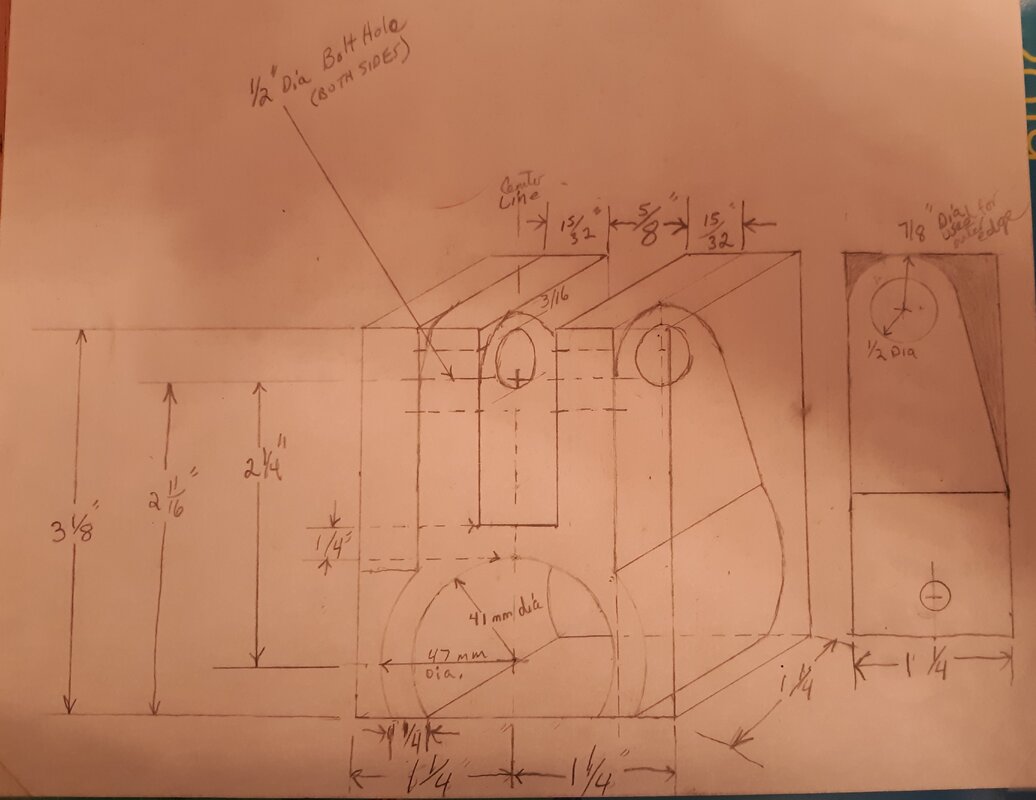

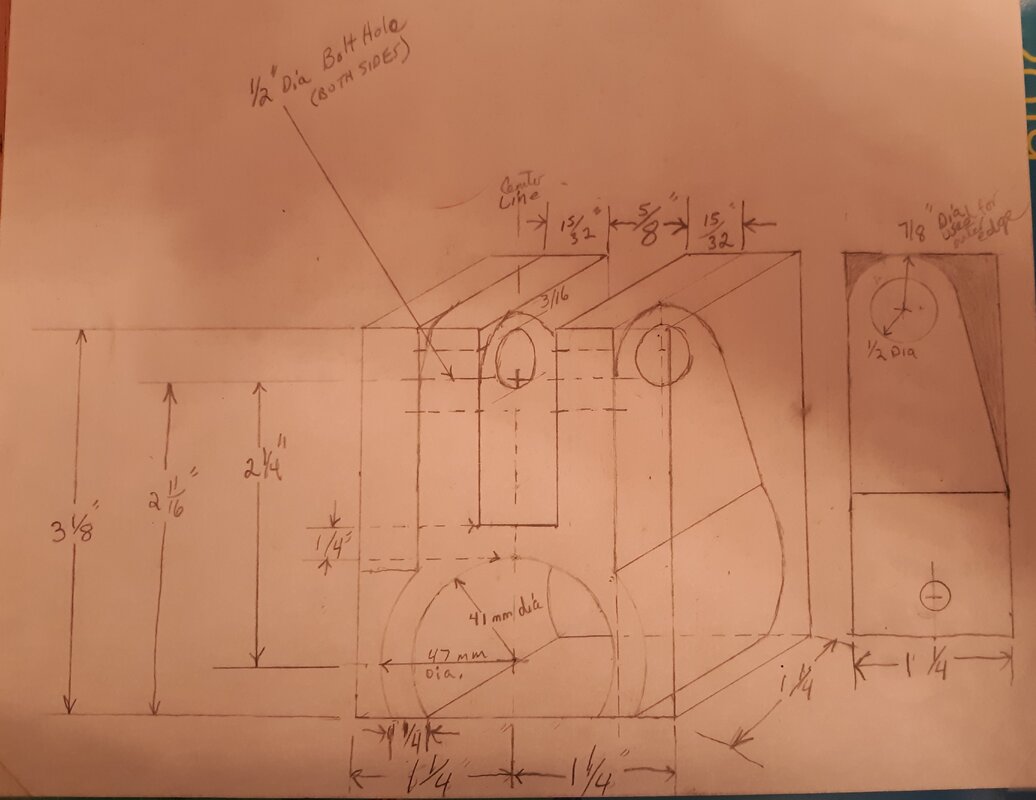

Not sure were the other pic went. On this my mind was trying to make the bracket from this block of metal, it is about 1/2 inch short for the entire part, so I made this up with the idea of two bolts on lower sides and maybe on in the middle of the top channel, if needed. It is a slide up into position and bolt into place bracket.

But you take the same block and just do a half 41mm dia. and flanges to the sides for bolts and you have the upper half of the bolt on bracket. The lower clamp halves would have to be made from 5/8" thick material, so I would have two lower halves to bolt to the upper single part. The block is 1 1/4" thick x 2 1/2" wide x 3 1/8" tall.

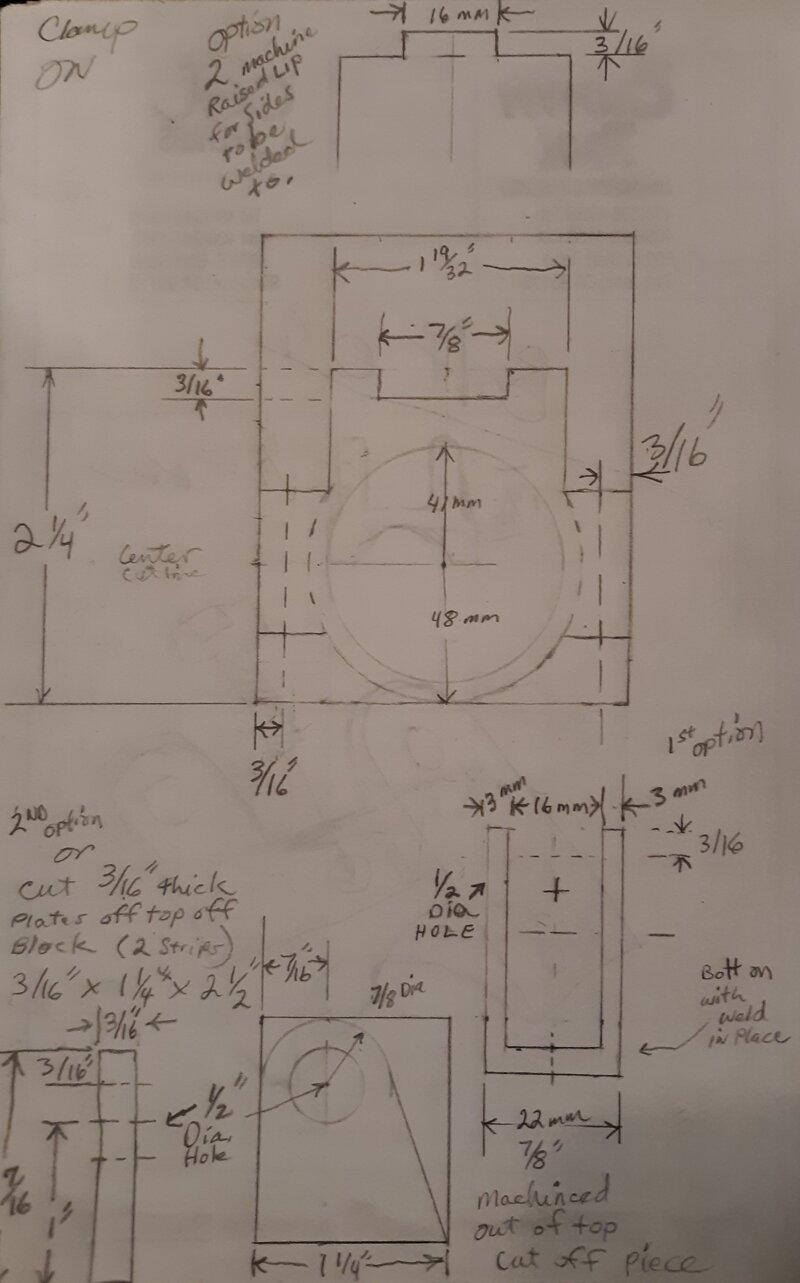

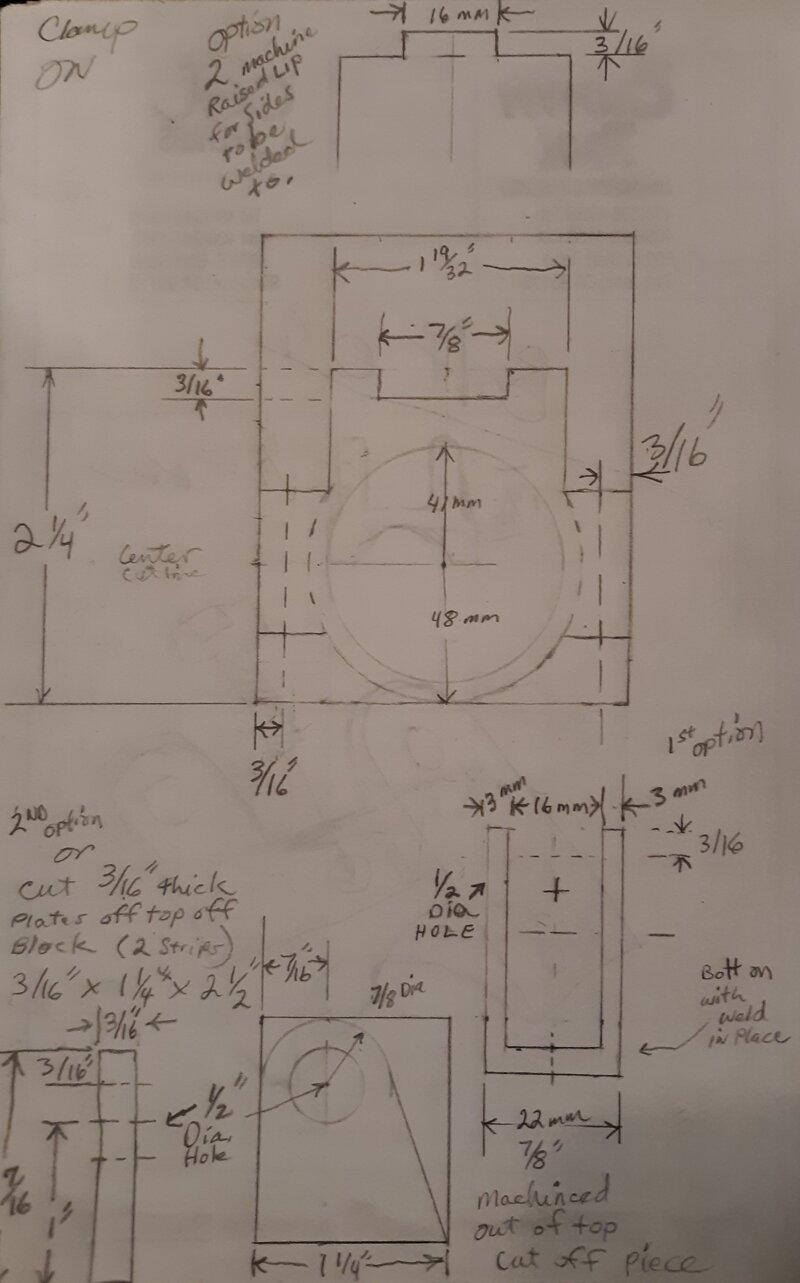

I finally got it small enough to post. The solid channel can be welded or bolted ?? not sure.The other drawing I did not get small enough, but it was making the clamp rings and a base out of the block, it left a cut off piece that was of size to make a upper Channel piece that could be bolted onto the base if not able to weld it in place.

I finally got it small enough to post. The solid channel can be welded or bolted ?? not sure.The other drawing I did not get small enough, but it was making the clamp rings and a base out of the block, it left a cut off piece that was of size to make a upper Channel piece that could be bolted onto the base if not able to weld it in place.

It will cost me, but the upper inner and outer edges of the tangs line up to the outside edge of the 41mm tube and this will allow me to have a place to drill and tap for mounting of the brake retention arm and the floating finder pivot arms. Left the outside tang the same for appearance.

So bolt on style OR just do the clamp on style, and than is this strong enough mount for the shock action ?

I did not find what I needed for the upper shock mount bracket. Than I remember my notes and what I was going to do originally. Not something I care to do now because I forgot about SS steal bending or twisting some when welded. I feel I should have done welding first than the machine work so all was good if possible.

So I want mounting brackets that clamp on to the fork tube. Found some choices, but none exactly what I needed or decided I wanted.

Not sure were the other pic went. On this my mind was trying to make the bracket from this block of metal, it is about 1/2 inch short for the entire part, so I made this up with the idea of two bolts on lower sides and maybe on in the middle of the top channel, if needed. It is a slide up into position and bolt into place bracket.

But you take the same block and just do a half 41mm dia. and flanges to the sides for bolts and you have the upper half of the bolt on bracket. The lower clamp halves would have to be made from 5/8" thick material, so I would have two lower halves to bolt to the upper single part. The block is 1 1/4" thick x 2 1/2" wide x 3 1/8" tall.

I finally got it small enough to post. The solid channel can be welded or bolted ?? not sure.The other drawing I did not get small enough, but it was making the clamp rings and a base out of the block, it left a cut off piece that was of size to make a upper Channel piece that could be bolted onto the base if not able to weld it in place.

I finally got it small enough to post. The solid channel can be welded or bolted ?? not sure.The other drawing I did not get small enough, but it was making the clamp rings and a base out of the block, it left a cut off piece that was of size to make a upper Channel piece that could be bolted onto the base if not able to weld it in place.It will cost me, but the upper inner and outer edges of the tangs line up to the outside edge of the 41mm tube and this will allow me to have a place to drill and tap for mounting of the brake retention arm and the floating finder pivot arms. Left the outside tang the same for appearance.

So bolt on style OR just do the clamp on style, and than is this strong enough mount for the shock action ?