DeathBySnuSnu

Old Redneck Motorhead

Now that is the big unknown.

Nowhere I can find is an actual spring rate listed for the harley shocks.

So i have no firm calculations.

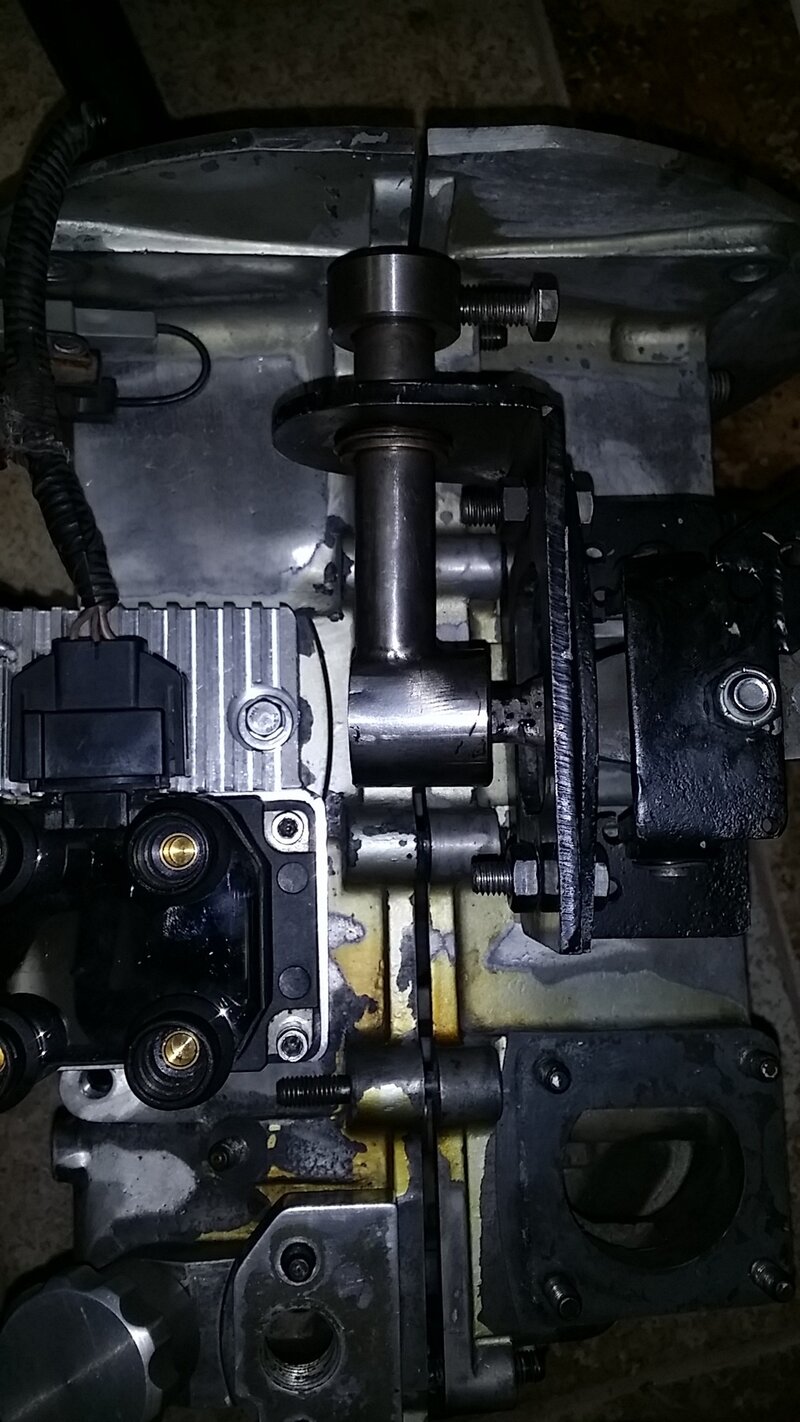

What I have done is take the weight of the rear of the donating motorcycle and backwards calculate it through the mechanical ratio. Then apply it to my weight and ratio. By this it is still way too much spring.

Now that this much is together I can set the axle down on a block then put my body weight on it and make it move about a quarter inch.

So far it looks promising.

But if not I will do something else.

Do really wish I had more real spring data about the shock.

It may very well support the weight but be terribly soft with no per inch data available.

Nowhere I can find is an actual spring rate listed for the harley shocks.

So i have no firm calculations.

What I have done is take the weight of the rear of the donating motorcycle and backwards calculate it through the mechanical ratio. Then apply it to my weight and ratio. By this it is still way too much spring.

Now that this much is together I can set the axle down on a block then put my body weight on it and make it move about a quarter inch.

So far it looks promising.

But if not I will do something else.

Do really wish I had more real spring data about the shock.

It may very well support the weight but be terribly soft with no per inch data available.