The Northstar project is started! As noted in another post, I bought a donor car a couple of weeks ago. I finally got the engine out of it yesterday. For those not familiar with the Caddy platform, the engine, transaxle tranny, hubs, suspension, etc are all mounted on the engine cradle. The body is bolted to the engine cradle/subframe with six bolts. Take the six bolts out, and lift the body off. Well, sort of... That power train is really jammed in there! It is very difficult to work on, and there must be 2 miles of wire in that car! I am a bit concerned about sorting all of that out, and getting the engine to run, and the tranny to shift outside of the car.

However...no guts, no glory!!!

Here's the engine in the car.

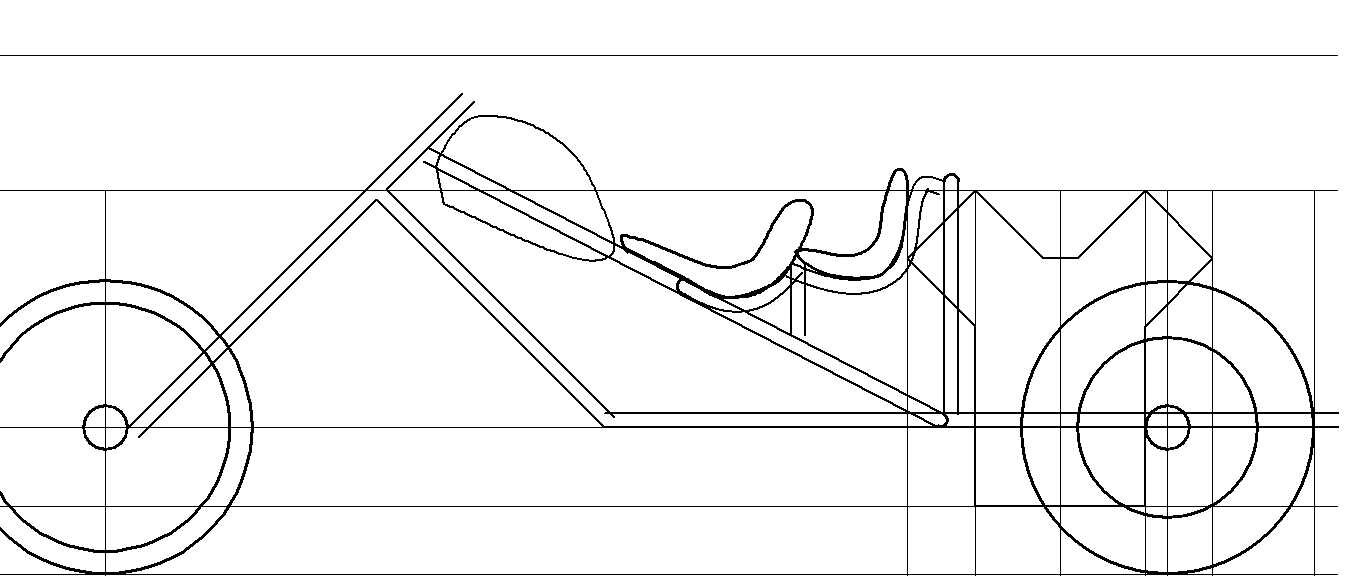

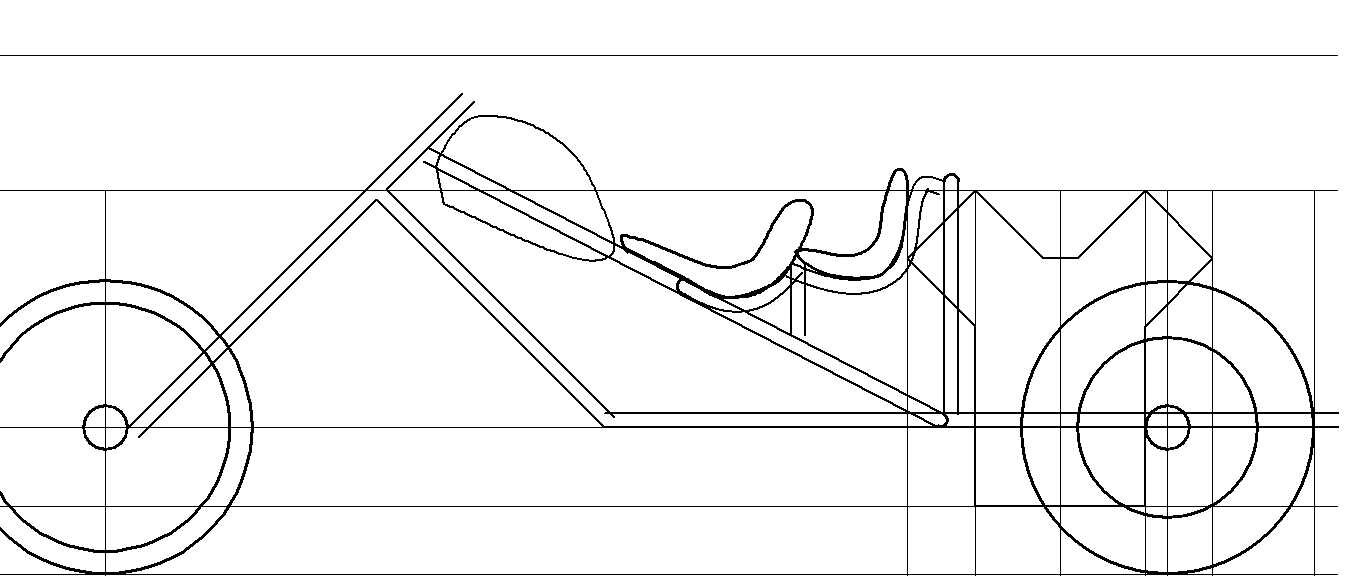

Here s my concept drawing. It is pretty basic, but I am trying to learn CAD (Computer Assisted Drawing), or as I prefer to call it, CHD (Computer Hindered Drawing). It's a work in progress, but I hope it conveys the concept. It is drawn to scale, 8 foot wheelbase, 10 feet overall.

Here is my first Mickey Mouse mock-up.

Another view. I am pretty encouraged by this. The proportions are pretty damn manageable, width is 5'9", and as I said, overall length is 10'.

I haven't weighed the power train yet, I hope to get that done tomorrow, at the local grain elevator. My best guess is in the neighbourhood of 700#. If you look at the location of the engine relative to the rear wheels, I am predicting that the weight will be fairly evenly distributed between the 3 wheels. Pulling a number out of thin air, if the completed trike weighs 1100#, that will put 366# on each wheel, without riders.

My Harley Road King weighs 650#, on 2 wheels, which equates to 325# per wheel. The Harley develops 65 horsepower. The Northstar develops 300 hp. Draw your own conclusions...

I would really appreciate feedback and advice. For starters, if anyone knowledgeable has suggestions for frame material, I would be very interested. I am debating DOM tube vs Extruded. Thanks for looking.

Glen

However...no guts, no glory!!!

Here's the engine in the car.

Here s my concept drawing. It is pretty basic, but I am trying to learn CAD (Computer Assisted Drawing), or as I prefer to call it, CHD (Computer Hindered Drawing). It's a work in progress, but I hope it conveys the concept. It is drawn to scale, 8 foot wheelbase, 10 feet overall.

Here is my first Mickey Mouse mock-up.

Another view. I am pretty encouraged by this. The proportions are pretty damn manageable, width is 5'9", and as I said, overall length is 10'.

I haven't weighed the power train yet, I hope to get that done tomorrow, at the local grain elevator. My best guess is in the neighbourhood of 700#. If you look at the location of the engine relative to the rear wheels, I am predicting that the weight will be fairly evenly distributed between the 3 wheels. Pulling a number out of thin air, if the completed trike weighs 1100#, that will put 366# on each wheel, without riders.

My Harley Road King weighs 650#, on 2 wheels, which equates to 325# per wheel. The Harley develops 65 horsepower. The Northstar develops 300 hp. Draw your own conclusions...

I would really appreciate feedback and advice. For starters, if anyone knowledgeable has suggestions for frame material, I would be very interested. I am debating DOM tube vs Extruded. Thanks for looking.

Glen