DK Custom Products

Sponsor

Test fitting the hardtail to the cut & prepped stock frame.

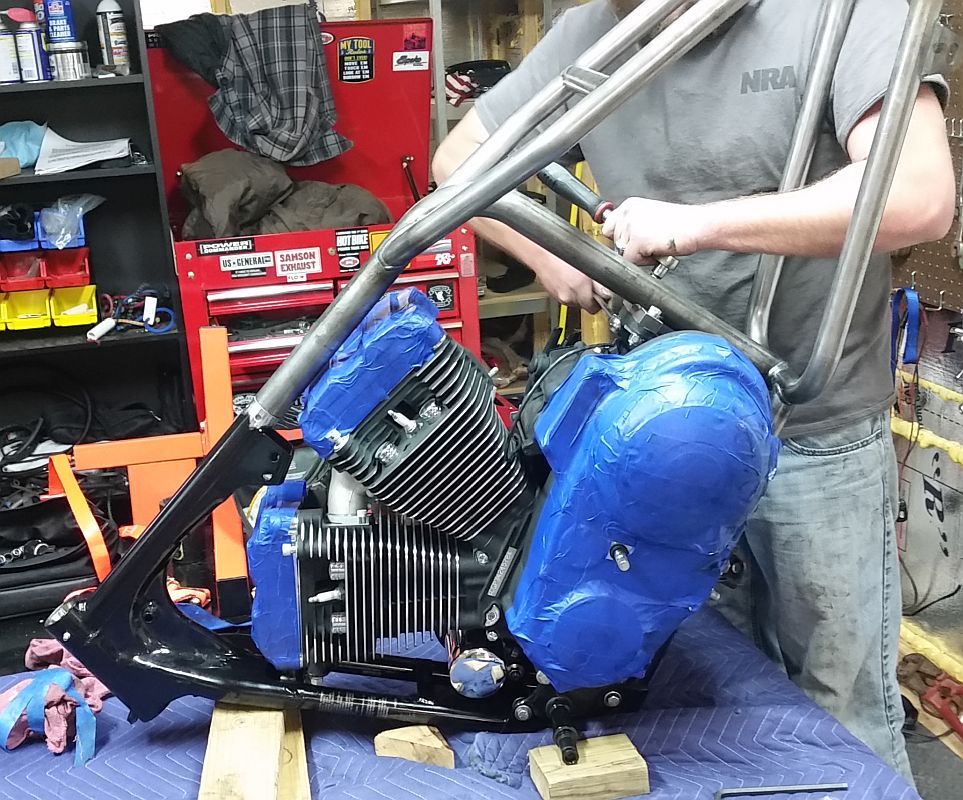

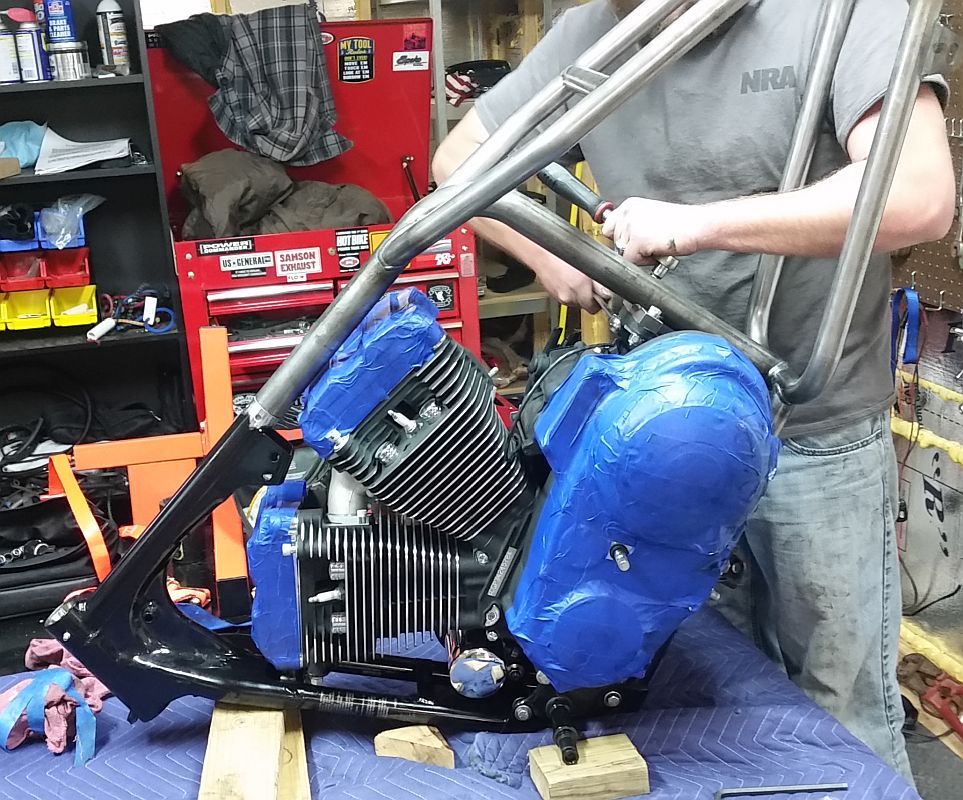

Everything looks good, so it's time to bolt the motor in to use it as a "jig" to get the frame perfectly aligned before welding.

10 bolts attach the engine to the original section of the frame...

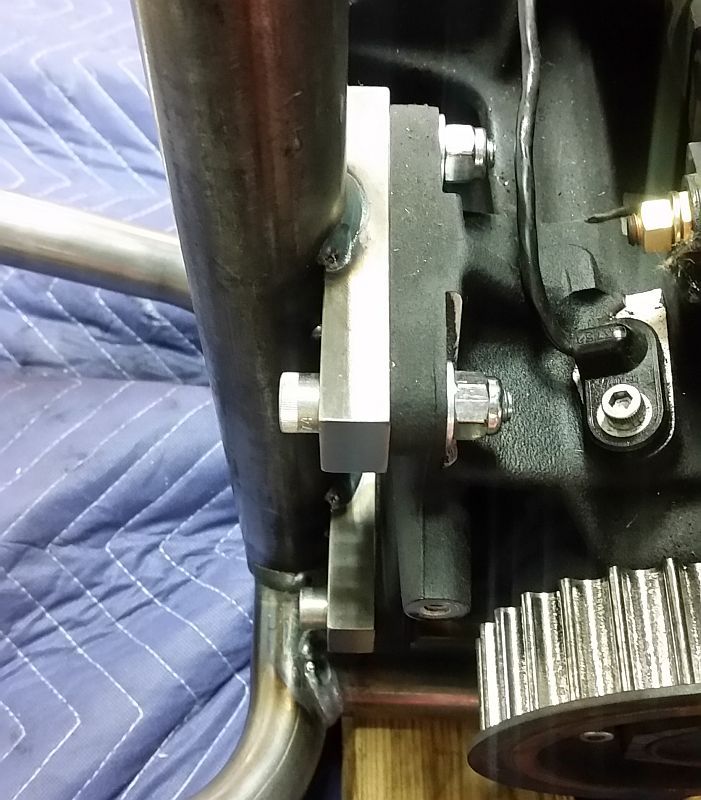

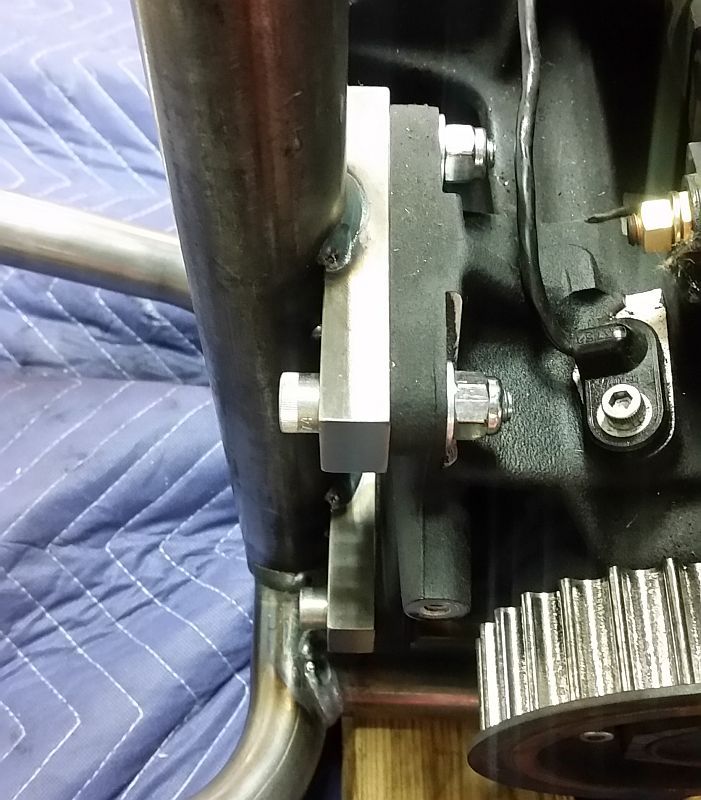

...and 4 more bolts (with 2 dowel pins) line up the hardtail section to the original perfectly.

Checking everything out...

...before we cover everything up and start welding.

Engine and trans are covered by 3 welding aprons...

...to protect them while welding.

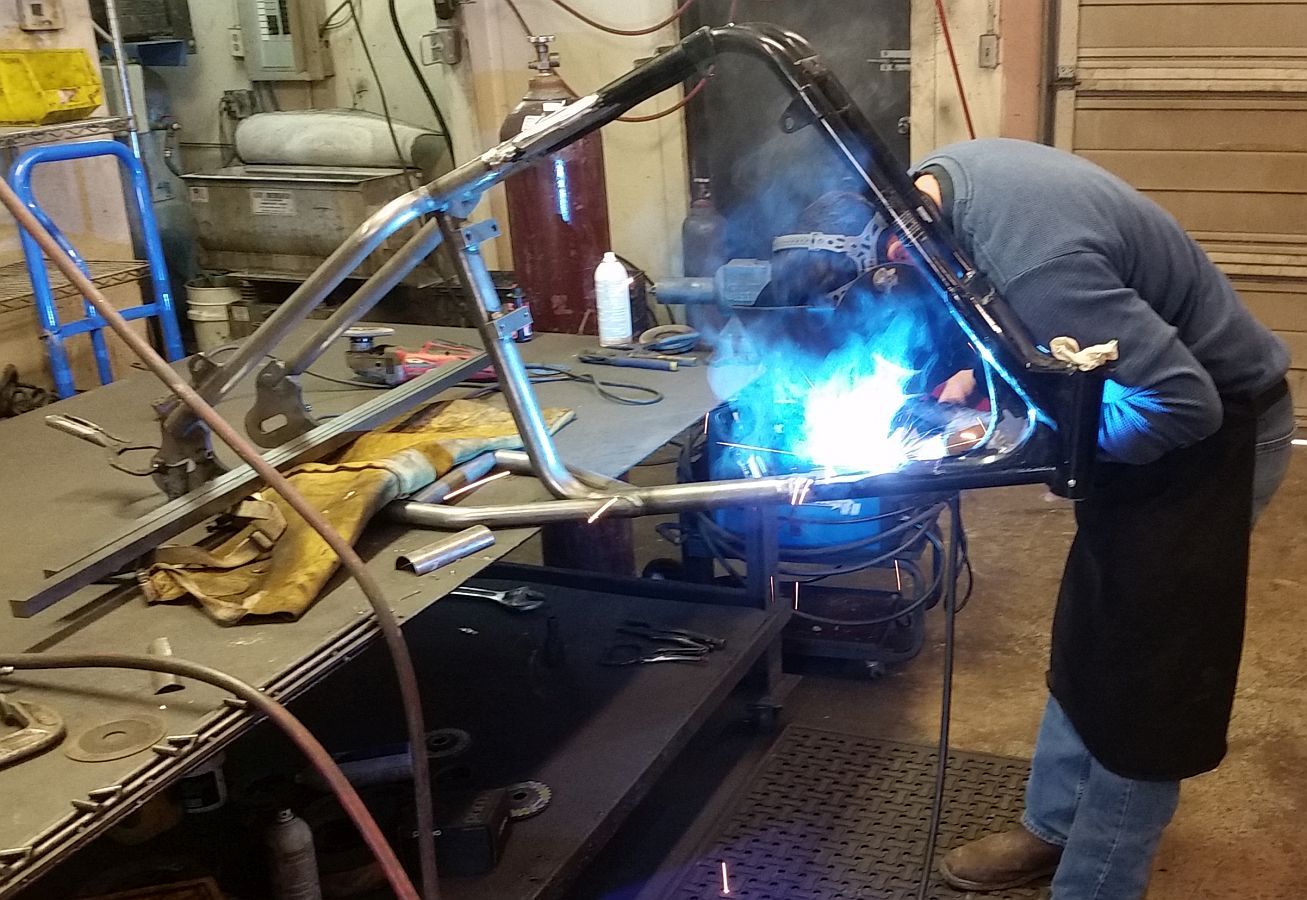

Got as much welded as we could with the engine in...enough to hold everything in place.

Took the engine back out.

Monday I'll take the frame to the shop and will finish welding the 3 joints.

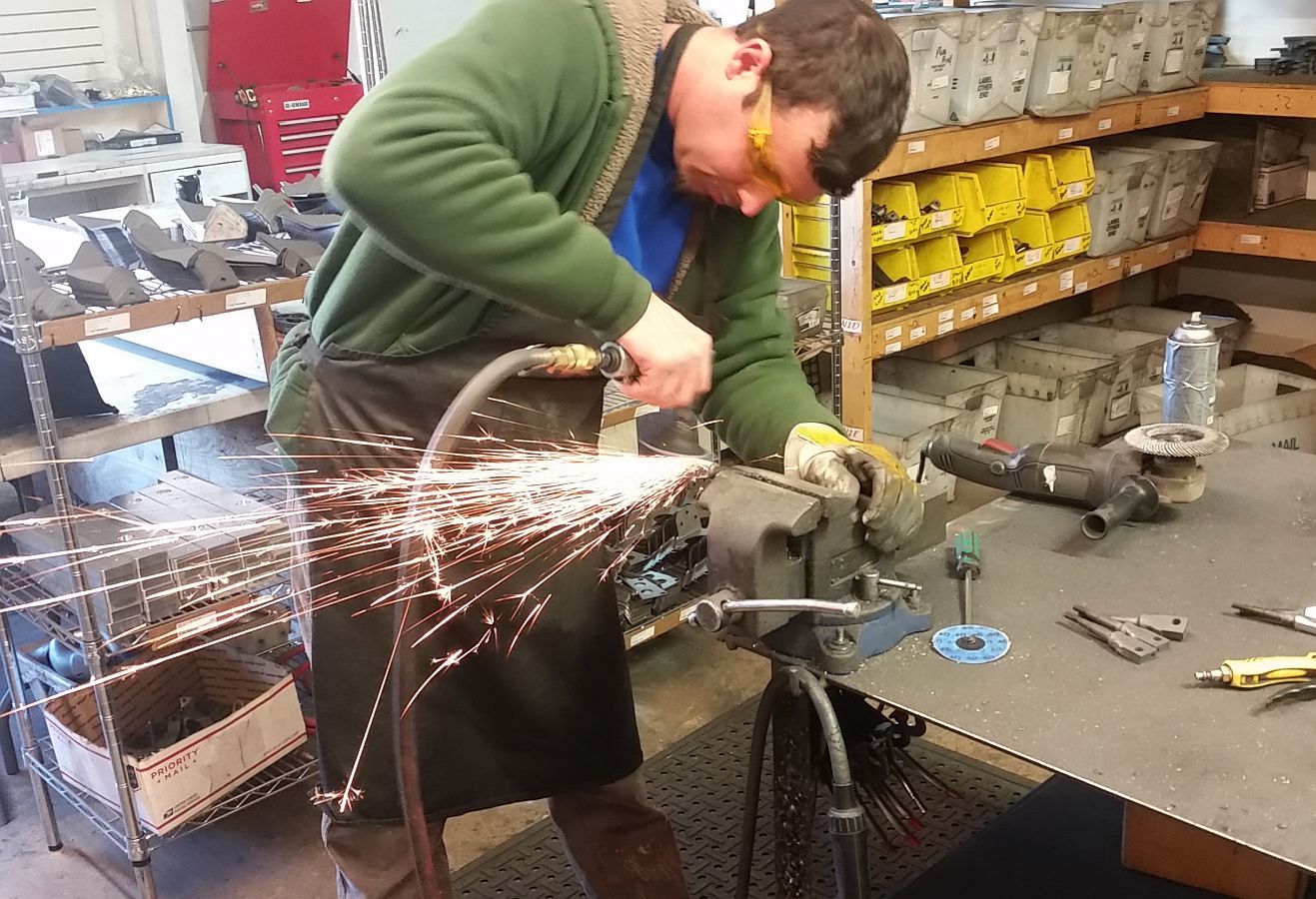

After that, the cutting, grinding, smoothing will start, along with mocking up a bunch of various components...some bought, some we have to design and build.

Kevin

Everything looks good, so it's time to bolt the motor in to use it as a "jig" to get the frame perfectly aligned before welding.

10 bolts attach the engine to the original section of the frame...

...and 4 more bolts (with 2 dowel pins) line up the hardtail section to the original perfectly.

Checking everything out...

...before we cover everything up and start welding.

Engine and trans are covered by 3 welding aprons...

...to protect them while welding.

Got as much welded as we could with the engine in...enough to hold everything in place.

Took the engine back out.

Monday I'll take the frame to the shop and will finish welding the 3 joints.

After that, the cutting, grinding, smoothing will start, along with mocking up a bunch of various components...some bought, some we have to design and build.

Kevin