DeathBySnuSnu

Old Redneck Motorhead

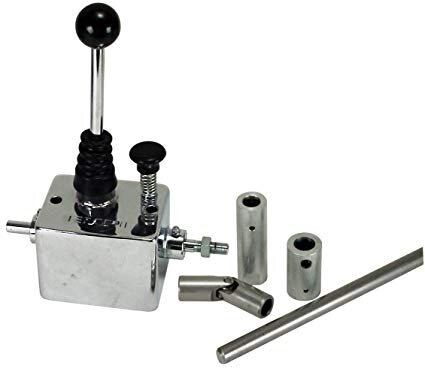

If you use/have a stock type shifter mount is is imperative that the rod goes square into the mount and centers up under the shifter.

You will be forever unhappy with the shifting and/or adjustment if that rod is not square.

That also means that the shifter can only swing some from the rear joint. Bit if you use a buggy universal joint style coupler at the trans you can swing it further.

Bending a lot of offset or welding in a bar that has a big zig zag offset can only somewhat work. It will have to move much farther side to side to get the rotation at the trans. It will also make the reverse lockout hard to set up, as typically it is the travel stop for the side to side or neutral gate.

You will be forever unhappy with the shifting and/or adjustment if that rod is not square.

That also means that the shifter can only swing some from the rear joint. Bit if you use a buggy universal joint style coupler at the trans you can swing it further.

Bending a lot of offset or welding in a bar that has a big zig zag offset can only somewhat work. It will have to move much farther side to side to get the rotation at the trans. It will also make the reverse lockout hard to set up, as typically it is the travel stop for the side to side or neutral gate.