i think you will find a nicer ride if you start with the pivot point about an inch below the axle

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

88 blazer trike

- Thread starter Fowler

- Start date

- Thread starter

- #342

OK I will plan on having the pivot point lower as you guys suggested

I just received my 1" hole saw in today It came real quick

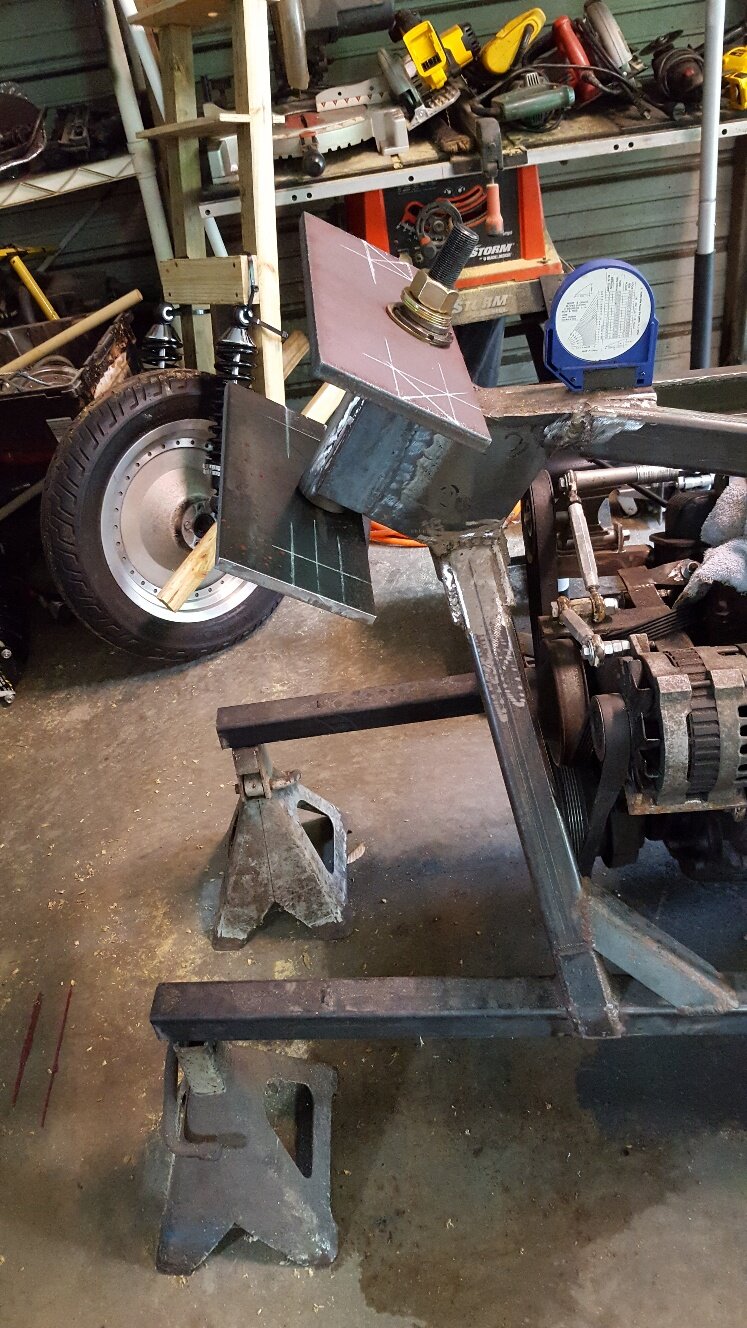

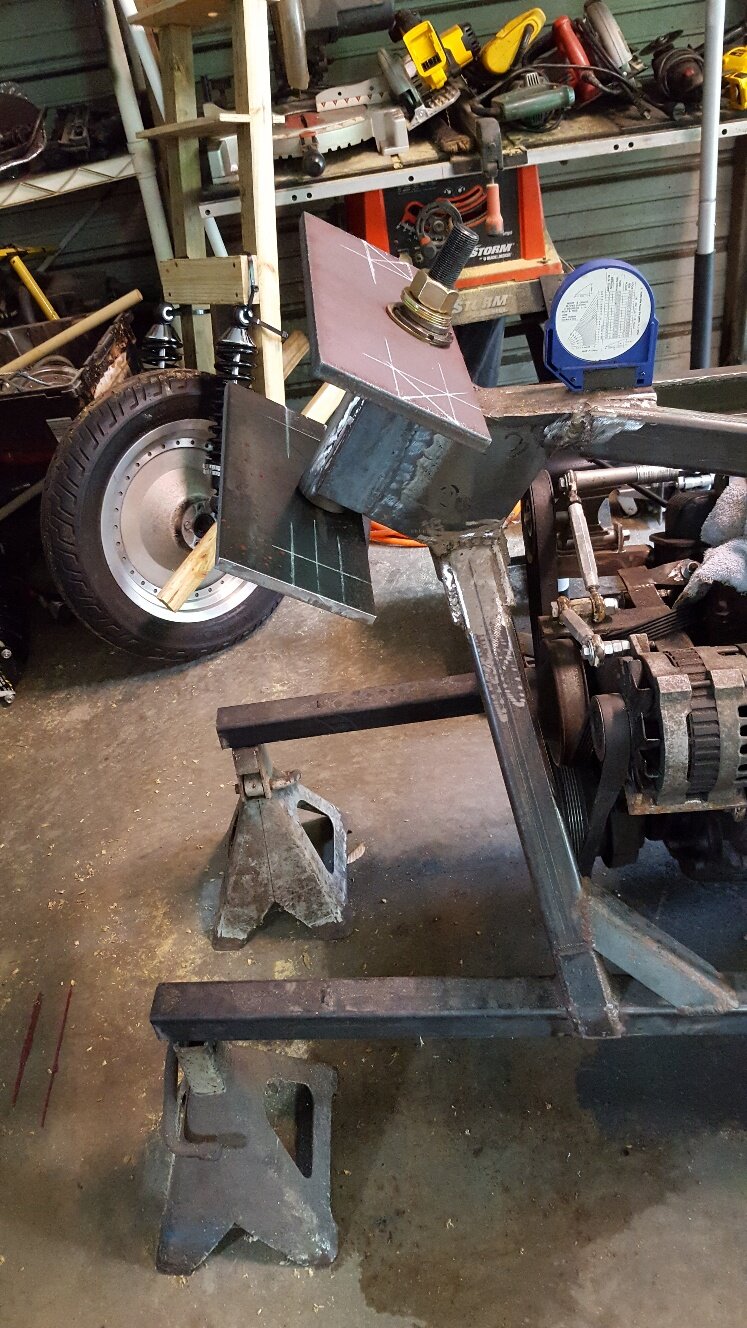

I'm debating if I want to make the forks wider. I have 1 inch clearance between the tire and the side of the fork but I have to mount my shocks a little off center of the rockers and down tubes to keep that 1 inch clearance

If I decide to go wider it will delay things. I have the money to buy more plate steel but don't have the time to go get it.

Im sucking up to the Ol'Lady now in case I need her to go get it

I just received my 1" hole saw in today It came real quick

I'm debating if I want to make the forks wider. I have 1 inch clearance between the tire and the side of the fork but I have to mount my shocks a little off center of the rockers and down tubes to keep that 1 inch clearance

If I decide to go wider it will delay things. I have the money to buy more plate steel but don't have the time to go get it.

Im sucking up to the Ol'Lady now in case I need her to go get it

OK I will plan on having the pivot point lower as you guys suggested

I just received my 1" hole saw in today It came real quick

I'm debating if I want to make the forks wider. I have 1 inch clearance between the tire and the side of the fork but I have to mount my shocks a little off center of the rockers and down tubes to keep that 1 inch clearance

If I decide to go wider it will delay things. I have the money to buy more plate steel but don't have the time to go get it.

Im sucking up to the Ol'Lady now in case I need her to go get it

didnt notice what u got the hole saw for but.. it will not make a very tight tolerance hole... it will be quite a bit over

- Thread starter

- #345

didnt notice what u got the hole saw for but.. it will not make a very tight tolerance hole... it will be quite a bit over

Well that sucks...

I was planning to use it for the neck stem holes in the upper and lower plate and the hold in the rockers for the axle. The axle is 3/4 but I am using a 1" spacer that reduces it down to 3/4"

I will have some extra plate steel and will drill a test hold in it first

Question???

what lubricant should I use when drilling these hole?

I need to be able to get something from the local hardware store, Lowes, Ace someplace like that

Jack Klarich

18000+ Posts

I need to be able to get something from the local hardware store, Lowes, Ace someplace like that

I use 3 in one or Marvel Mystery oil for drilling steel

Well that sucks...

I was planning to use it for the neck stem holes in the upper and lower plate and the hold in the rockers for the axle. The axle is 3/4 but I am using a 1" spacer that reduces it down to 3/4"

I will have some extra plate steel and will drill a test hold in it first

Question???

what lubricant should I use when drilling these hole?

I need to be able to get something from the local hardware store, Lowes, Ace someplace like that

not much chance of that being a good fit... even a good drill will drill over.. best bet is a 31/32 drill an a 1" reamer esp for the rocker

LarryA

500+ Posts

have never used a hole saw for drilling thick steel.....but would agree with stacebg that even with a pilot the 1 in. hole saw will wander enough to be oversize. can you find a local machine shop or weld shop that could plasma or waterjet those holes? or even drill undersize and ream to size. or worse case, buy a drill bit and adjustable reamer on e-bay, I see a lot of crichley adjustable reamers sets fairly cheap. I have drilled a lot of 3/4 to 1 in holes on my 1/2 inch drill press......also have drilled many holes with an old post drill fasted to the garage wall .....they had a rachet power feed that worked well...of course you cranked by hand. with a slow turning bit and heavy feed pressure I have drilled thru leaf springs on occasion.

LarryA

500+ Posts

Bob if you drill or hole saw...you will need to ream the hole to get it straight and round. If the drill bit is sharpened correctly, a 31/32 hole should clean up with a 1 in. reamer. That is why you drill a sample hole in a piece of scrap steel. if in doubt use a 15/16 bit. The reamer will pull harder with the smaller bit of course. with an adjustable reamer you can increase hole size in steps. Working 1n. holes will require a drill press that turns slowly. the adjustable reamers are to be turned by hand.....the chucking reamers are used in a drill press turning slowly with plenty of oil....cutting oil preferred, but engine oil works, not as well, but I don't like the smell of hot motor oil... For 4 drilled and reamed holes farming out to a machine shop may be cheaper? Others may have ideas or suggestions. Good luck on this project.

- Thread starter

- #351

but getting time to take it to a machine shop is not easy.

I just looked at my hole saw. It is not actually 1 inch. It is 25mm (from Japan)

I just picked up some cutting oil from Ace hardware I am going to try it tomorrow on some scrap 1/4 plate

If that does not work I will buy a 31/32 drill bit

I just looked at my hole saw. It is not actually 1 inch. It is 25mm (from Japan)

I just picked up some cutting oil from Ace hardware I am going to try it tomorrow on some scrap 1/4 plate

If that does not work I will buy a 31/32 drill bit

- Thread starter

- #352

so what am I looking for in a drill bit

https://www.ebay.com/sch/i.html?_fr....X31/32+dr.TRS0&_nkw=31/32+drill+bit&_sacat=0

https://www.ebay.com/sch/i.html?_fr....X31/32+dr.TRS0&_nkw=31/32+drill+bit&_sacat=0

LarryA

500+ Posts

ya the 14 dollar one should work. I usually drill a pilot hole slightly smaller than the thickness of the drill web......that is the width across the point of the drill bit. It helps the drill feed easier. A larger pilot hole can sometimes let the bit wander and chatter. experiment on a scrap piece. The new bit should drill close to on size. At work we sometimes needed a larger hole than the bit had available, so we would hand sharpen the bit, grinding uneven cutting edge lengths, to make it drill slightly oversize.....not always successful!

LarryA

500+ Posts

seems like a pretty good fit!

looks good... i am surprised

vwbug72501

700+ Posts

Oh Yea of little faith... . I've had good luck with hole saws on projects like this. Some caveats: Slow speed and plenty of lube/coolant. Subsequent holes may not be as pretty or precise. A second hole saw is always a good investment......You'll use it again sometime anyway.

. I've had good luck with hole saws on projects like this. Some caveats: Slow speed and plenty of lube/coolant. Subsequent holes may not be as pretty or precise. A second hole saw is always a good investment......You'll use it again sometime anyway.

As for drill bits.....MADE IN USA!!!! My experience with Made in China is that they aren't worth the blisterpack they come in.

These guys are pricey but their stuff is good! https://www.mcmaster.com/#drill-bits/=1e7nixt

Again, you'll use it again sometime.

Prepare for the Apocalypse. Collect tools. The man you can fix things won't starve!:clapping:

As for drill bits.....MADE IN USA!!!! My experience with Made in China is that they aren't worth the blisterpack they come in.

These guys are pricey but their stuff is good! https://www.mcmaster.com/#drill-bits/=1e7nixt

Again, you'll use it again sometime.

Prepare for the Apocalypse. Collect tools. The man you can fix things won't starve!:clapping:

- Thread starter

- #358

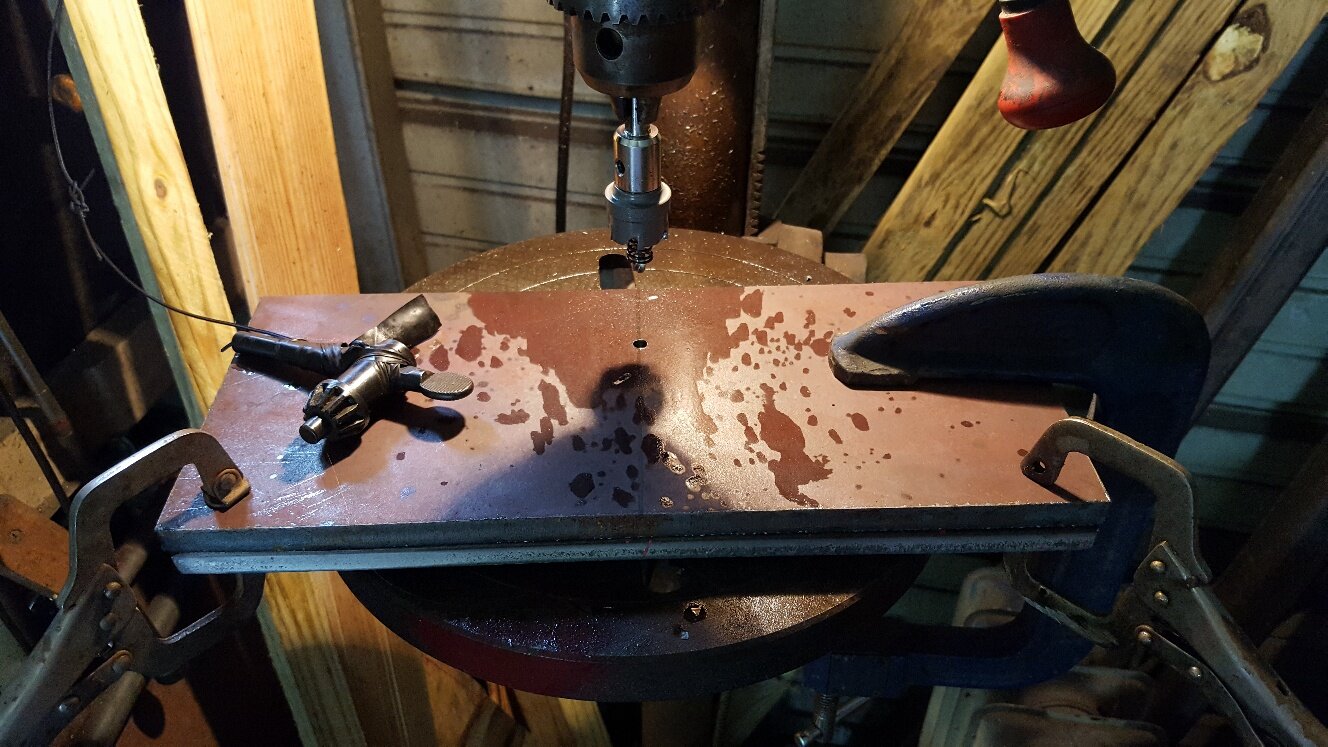

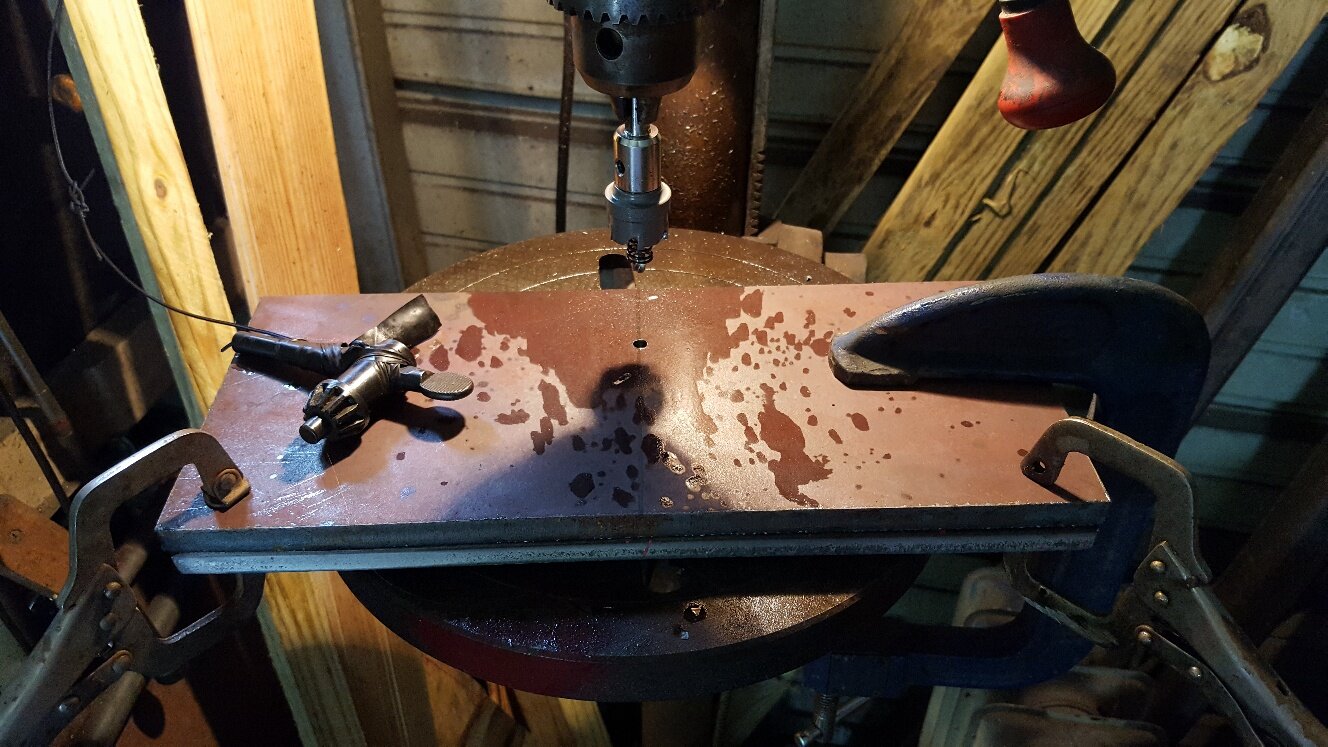

Started by drilling a pilot hole through both plates

Had to take it down to 1 plate at a time because it would not go through both

Also it started clogging up I had to clean it a lot

It went through 1 plate at a time fine just had to clean and oil it often

on the trike. The stem bolt fit real well but it is to long. I will have to get 3/4 inch more thread cut in it

Once I am finished making it I will have to figure out something for bearing seals. We had talked about this in the past and you all had some good ideas

Next weekend I will work on it more. I have to start painting a room now. (promised the Ol'Lady)

Had to take it down to 1 plate at a time because it would not go through both

Also it started clogging up I had to clean it a lot

It went through 1 plate at a time fine just had to clean and oil it often

on the trike. The stem bolt fit real well but it is to long. I will have to get 3/4 inch more thread cut in it

Once I am finished making it I will have to figure out something for bearing seals. We had talked about this in the past and you all had some good ideas

Next weekend I will work on it more. I have to start painting a room now. (promised the Ol'Lady)

vwbug72501

700+ Posts

Nice work Bob. Will cutting longer threads on a grade 8 bolt be possible ? Will it mess up the integrity of the grade 8 hardness? I thought that the bolts were manufactured and then hardened to grade 8 specs including the thread areas.

Maybe wait until you add the thicknesses of the bearing seal solution and then split the difference and add welded on spacers to the top and bottom tree outside surfaces. That would give you a little more load bearing surface area on the neck bolt.

Maybe wait until you add the thicknesses of the bearing seal solution and then split the difference and add welded on spacers to the top and bottom tree outside surfaces. That would give you a little more load bearing surface area on the neck bolt.

LarryA

500+ Posts

Bob ....you have made me a believer in hole saws! That's true Tom.....maybe seal cups and sleeves will eat up some of the excess bolt length. I do think, the cutting of additional threads would definitley reduce the grade 8 factor, but the bolt would still have plenty of strength. the tension on the bolt would be only a few ft/lbs at the most, and the shear strength of the bolt would be much more than the fork assembly could stand without bending or breaking....just my .02.

Welcome to the Trike Talk Community

Join our vibrant online community dedicated to all things Trikes! Whether you're a seasoned rider or just starting out, this is the place to share experiences, tips, and stories about your three-wheeled adventures. Explore modifications, maintenance advice, and rides, all while connecting with fellow trike enthusiasts from around the globe

Forum statistics

Trike Talk Community

Welcome to a community dedicated to the most diverse and fastest growing powersports segment, Motorcycle Trikes. Come join the discussion about the best makes and models, popular modifications and proven performance hacks, trike touring and travel, maintenance, meetups and more!

Register Already a member? LoginForum statistics