Rmitchell55

850+ Posts

A tank hanging down that low with no protection is just asking for some type of road hazard to go through the bottom.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

A tank hanging down that low with no protection is just asking for some type of road hazard to go through the bottom.

Big question, can I check and set my Toe in on the rear tires in my garage ? I thought about this, and all I thought of was chalking out a large T square on the floor, roll the trike rear end over the head of the T align the wheel axle to the line, put the front tire's center line on the leg line of the T. Now if the rear is really out of align I might have one axle over the line and the other side off, forward of the line for severe toe in, behind the line would be negative toe in, dead on the line should be zeroed in.

and the left side once removed

and the left side once removed  still need smooth out that welded area.

still need smooth out that welded area. I just happened to have the bolt size I needed, but now I wonder about vibration of rear end effecting the new mount. I measured 7 3/4 inch's needed to extend the lamp out to basic same area, do we think that 1/4 inch steel would be firm at that length, maybe it is 3/16 thick. I guess just try it and see.

I just happened to have the bolt size I needed, but now I wonder about vibration of rear end effecting the new mount. I measured 7 3/4 inch's needed to extend the lamp out to basic same area, do we think that 1/4 inch steel would be firm at that length, maybe it is 3/16 thick. I guess just try it and see. Now I do not remember where those large washer/spacers went, no paint on them, so I believe they where on the inside of the drum on the spline.

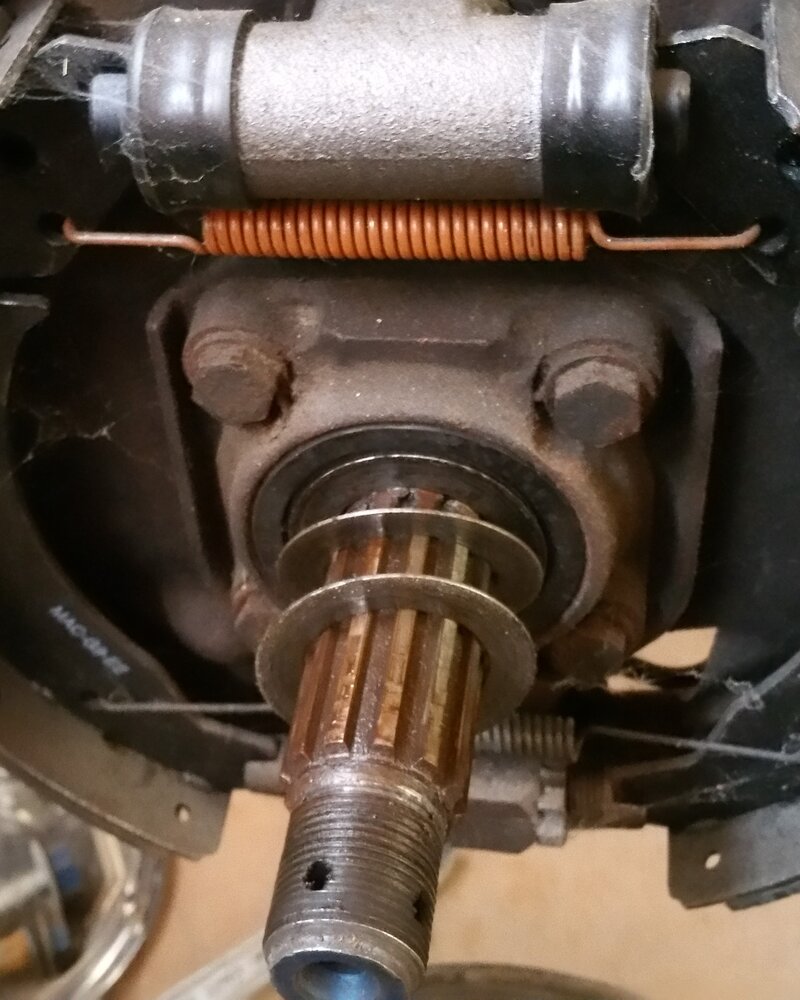

Now I do not remember where those large washer/spacers went, no paint on them, so I believe they where on the inside of the drum on the spline.  and there is this spacer on the outside along with 4 shim's on each side that are against the bearing.

and there is this spacer on the outside along with 4 shim's on each side that are against the bearing. I do remember the left side had wider brake pad's on it and bad slave cylinder, and it was shimmed up more than the right side. Why only one set of brake shoes in the old parts, kept those that where the same size as the new ones. Shim's, think I split up the thin ones on the axle spline, 4 on each side, because it keeps the drum from pushing all the way in against the bearing, plus it looks like to keep the seal from damage, and than the drum has to align over the brake pads correctly for proper operation. Does any of this look normal or correct ? Out side spacer seems to be taking up open space on the spline keeping the axle nut on the threaded area and inline with carter pin hole.

I do remember the left side had wider brake pad's on it and bad slave cylinder, and it was shimmed up more than the right side. Why only one set of brake shoes in the old parts, kept those that where the same size as the new ones. Shim's, think I split up the thin ones on the axle spline, 4 on each side, because it keeps the drum from pushing all the way in against the bearing, plus it looks like to keep the seal from damage, and than the drum has to align over the brake pads correctly for proper operation. Does any of this look normal or correct ? Out side spacer seems to be taking up open space on the spline keeping the axle nut on the threaded area and inline with carter pin hole. and here is the instrument panel I did

and here is the instrument panel I did  and Belle's new goggles

and Belle's new goggles She was to be my wife's new friend, she is, but she picked me as her buddy. She is always with me, at my feet, or sleeping up against me. Ever fight with a dog for cover's ? Belle watch's me and is always making me take breaks, or even naps if needed. My condition does limit me and I can push myself to far to much, Belle seems to be my care taker these days. Not sure if she will ride on the trike with me, but she loves here goggles.

She was to be my wife's new friend, she is, but she picked me as her buddy. She is always with me, at my feet, or sleeping up against me. Ever fight with a dog for cover's ? Belle watch's me and is always making me take breaks, or even naps if needed. My condition does limit me and I can push myself to far to much, Belle seems to be my care taker these days. Not sure if she will ride on the trike with me, but she loves here goggles.Welcome to a community dedicated to the most diverse and fastest growing powersports segment, Motorcycle Trikes. Come join the discussion about the best makes and models, popular modifications and proven performance hacks, trike touring and travel, maintenance, meetups and more!

Register Already a member? Login