DeathBySnuSnu

Old Redneck Motorhead

We had some severe rain the past couple night.

Right now it is cloudy and almost drizzling. Hot hot and muggy.

I gotta patch up a mower and cut my grass this weekend. Already almost knee high in spots.

I think CB performance has stock type springs.

The bearings are probably regular industrial sizes. Look for numbers on the edges. Something like 6208 2rs....not saying that is the number....just an example. Then an industrial supply or bearing specialty store will have them for a lot less than the car parts store.

Yeah....mine is purdy far out there. Very little functions as vw intended anymore.

Right now it is cloudy and almost drizzling. Hot hot and muggy.

I gotta patch up a mower and cut my grass this weekend. Already almost knee high in spots.

I think CB performance has stock type springs.

The bearings are probably regular industrial sizes. Look for numbers on the edges. Something like 6208 2rs....not saying that is the number....just an example. Then an industrial supply or bearing specialty store will have them for a lot less than the car parts store.

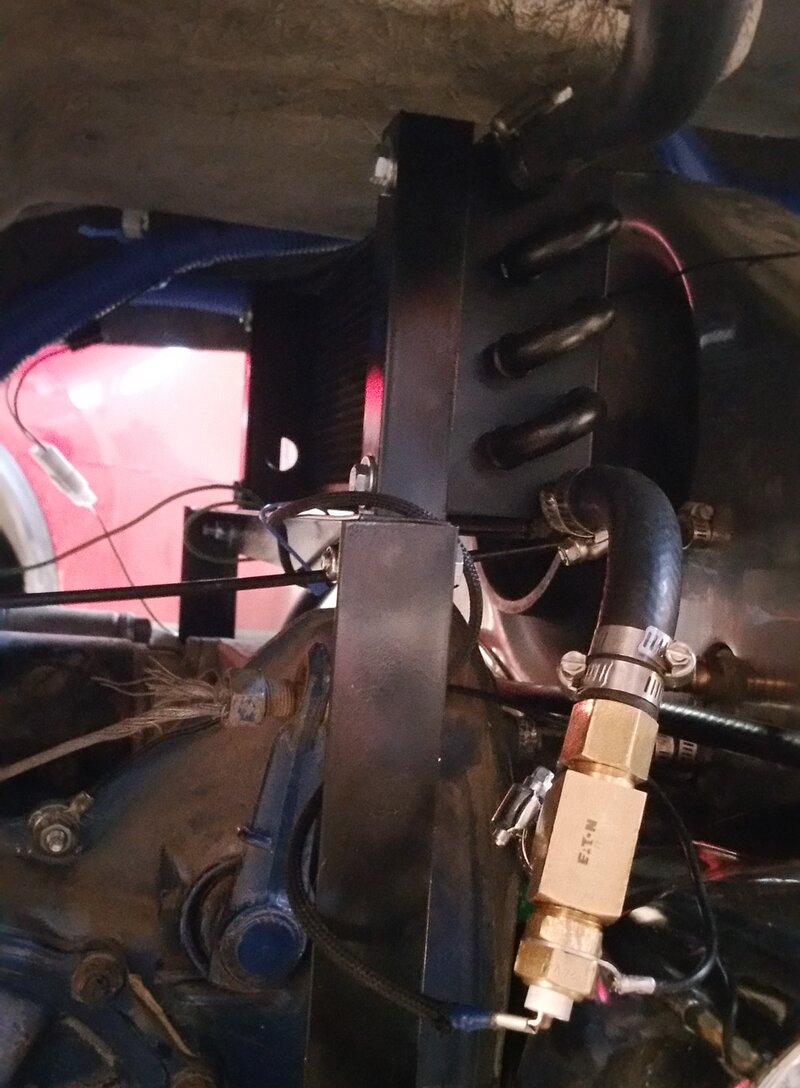

Yeah....mine is purdy far out there. Very little functions as vw intended anymore.