grandpanystrom61

New member

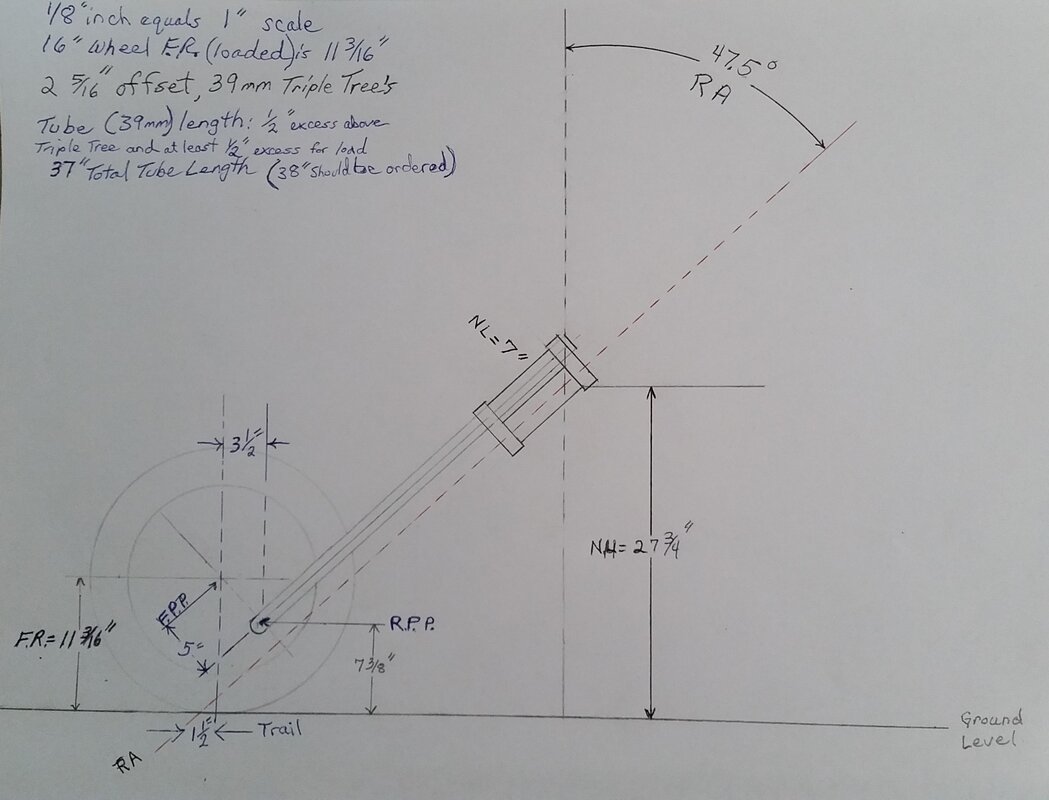

No real update today, other than I got lost a bit. I did try the reverse Triple Trees and liked how lined up and looked, but I would have to relocate foot pedal assembly and brake MC, so I will not be doing that.

What I drew on paper is not exactly what I am getting physically out in the garage with the trike. I have something wrong, maybe how I am finding angles, time will figure it out, I think it is how I am doing the rake angle, short on paper and yet longer in the garage?

Need to read things again, right down all the key points and tips that apply to this.

Wow, took a bit, but I got it figured out, the 47.5 degree angle is to be at the top of the neck, when I went from the ground line to get the 47.5 degree angle I actually shorted myself, so all was off, but it matching up now.

What I drew on paper is not exactly what I am getting physically out in the garage with the trike. I have something wrong, maybe how I am finding angles, time will figure it out, I think it is how I am doing the rake angle, short on paper and yet longer in the garage?

Need to read things again, right down all the key points and tips that apply to this.

Wow, took a bit, but I got it figured out, the 47.5 degree angle is to be at the top of the neck, when I went from the ground line to get the 47.5 degree angle I actually shorted myself, so all was off, but it matching up now.

Last edited: