Good day to all, I just watched a racing engine mechanic show how to find a estimate value of your engine stroke.

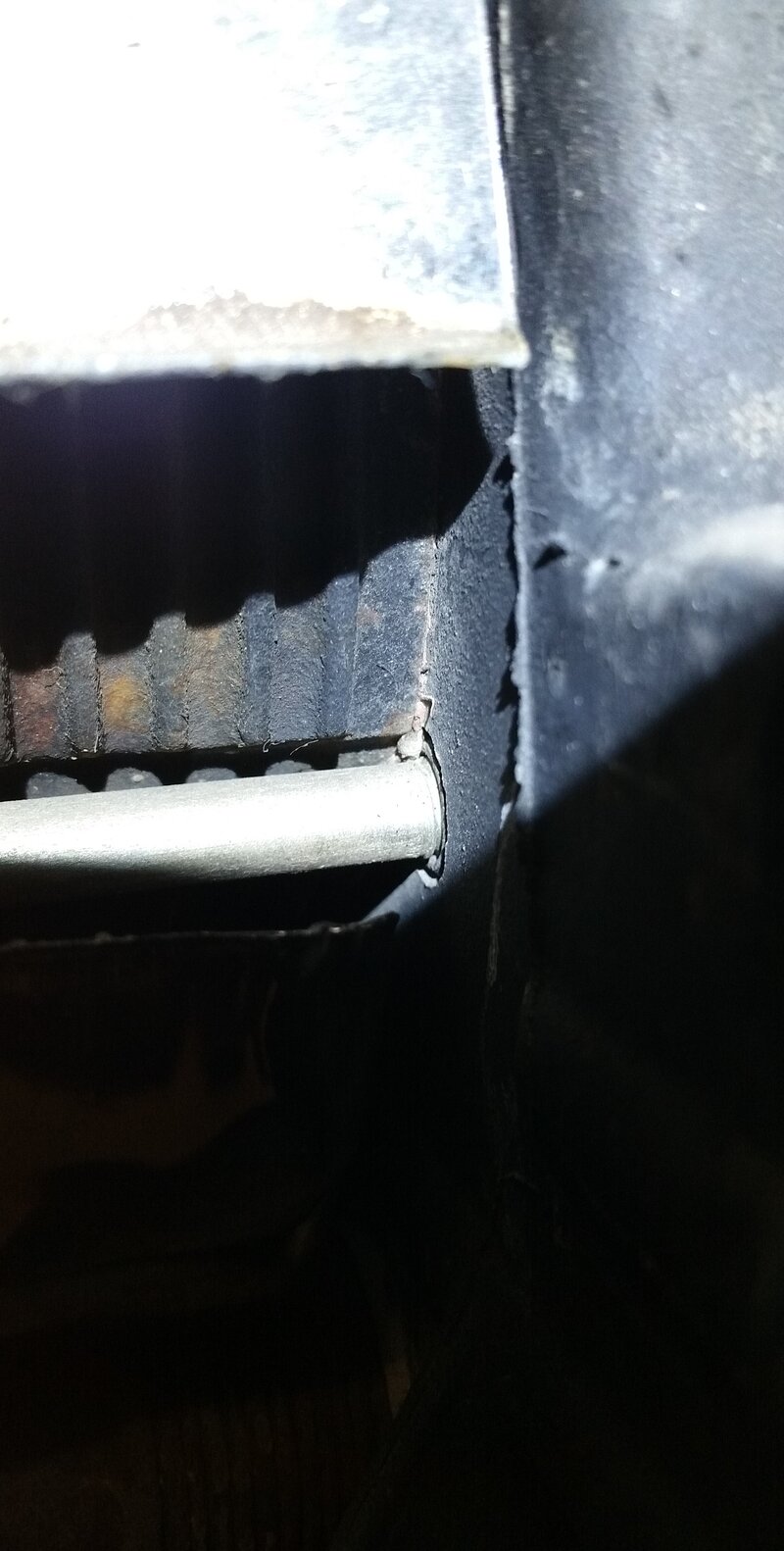

With a thin straight rod of metal, slide it down the spark plug hole until it stops. Note what you are aligning with to make the mark on the rod. Remember this area as the next mark has to be at the same point of reference. IF lined with the tin shrouds, you can use this edge, just make sure same spot when marking the rod for the second time.

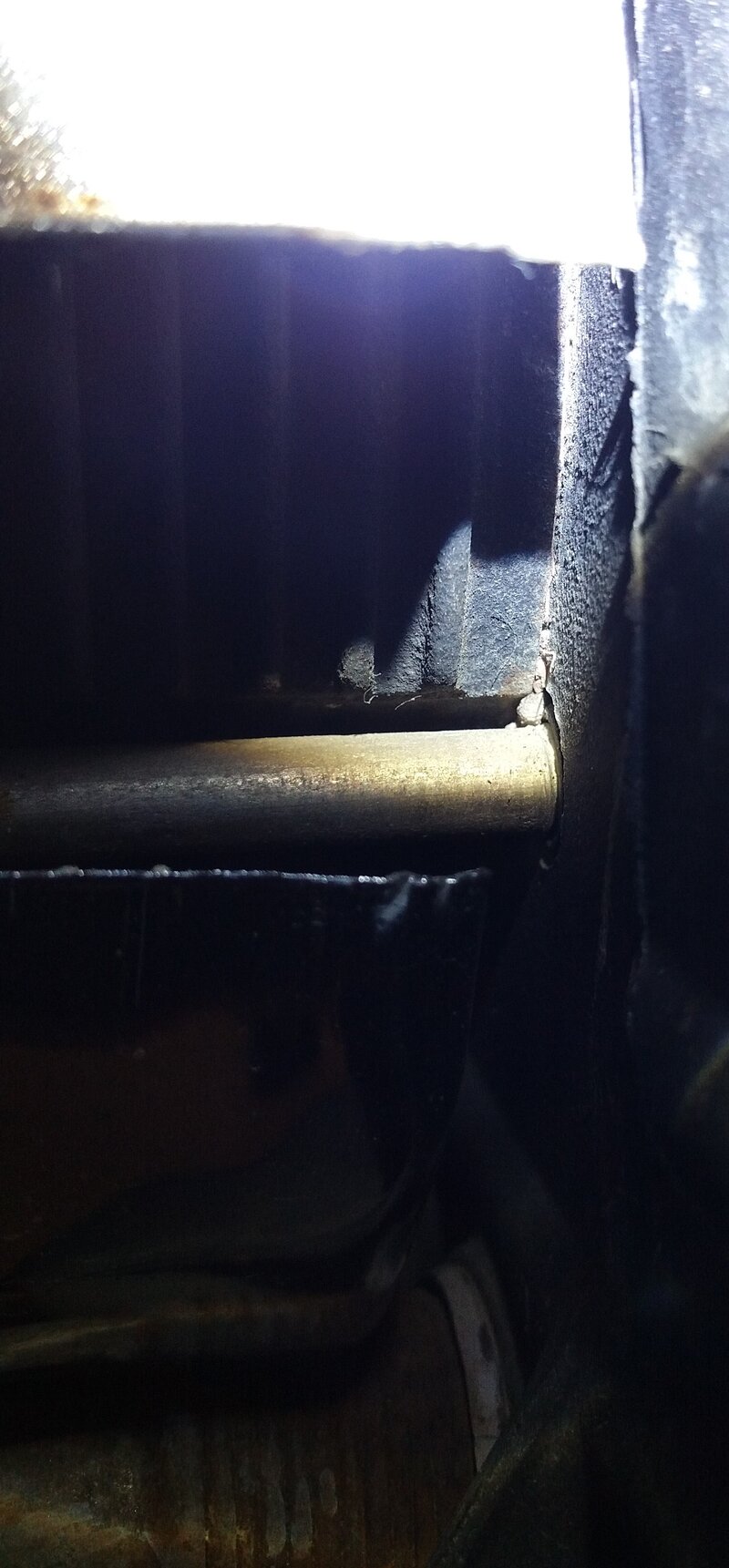

Now I rotated CCW to BTDC mark, that put's #2 at TDC, and #1 down at the end of its travel, slide the rod down #1 cylinder and mark it. Now you can take the rod and measure the distance between marks, this gives you a rough estimate of what the stoke is. My 74 1600 DP, which I know was rebuilt at least once, measured 76.14 mm, checked the process twice and 2nd time was 76.46mm, so straight rod and same angle and reference mark is the key to accurate measurement.

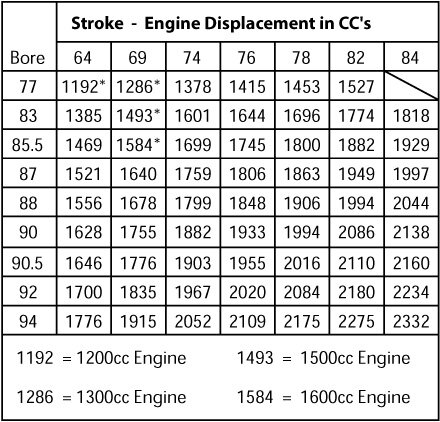

Now I will look up and see if one can have such a thing as a 76mm stroke, I read about 69mm and 84mm so far in other articles. Getting interesting.

With a thin straight rod of metal, slide it down the spark plug hole until it stops. Note what you are aligning with to make the mark on the rod. Remember this area as the next mark has to be at the same point of reference. IF lined with the tin shrouds, you can use this edge, just make sure same spot when marking the rod for the second time.

Now I rotated CCW to BTDC mark, that put's #2 at TDC, and #1 down at the end of its travel, slide the rod down #1 cylinder and mark it. Now you can take the rod and measure the distance between marks, this gives you a rough estimate of what the stoke is. My 74 1600 DP, which I know was rebuilt at least once, measured 76.14 mm, checked the process twice and 2nd time was 76.46mm, so straight rod and same angle and reference mark is the key to accurate measurement.

Now I will look up and see if one can have such a thing as a 76mm stroke, I read about 69mm and 84mm so far in other articles. Getting interesting.