DK Custom Products

Sponsor

After replacing the worn heim joints there was still play when we rocked the rear wheels.

It was less than before replacing the heim joints, but there was still a significant amount of movement and audible clicking/clanking.

We thought it must be the rear axle bearings going bad. So we removed the rear axle, and boy what a surprise!

The bearing was not bad, no play in it, and no grease leaking out of the sealed bearing.

What we did discover is that the entire bearing was rocking back and forth in the axle housing.

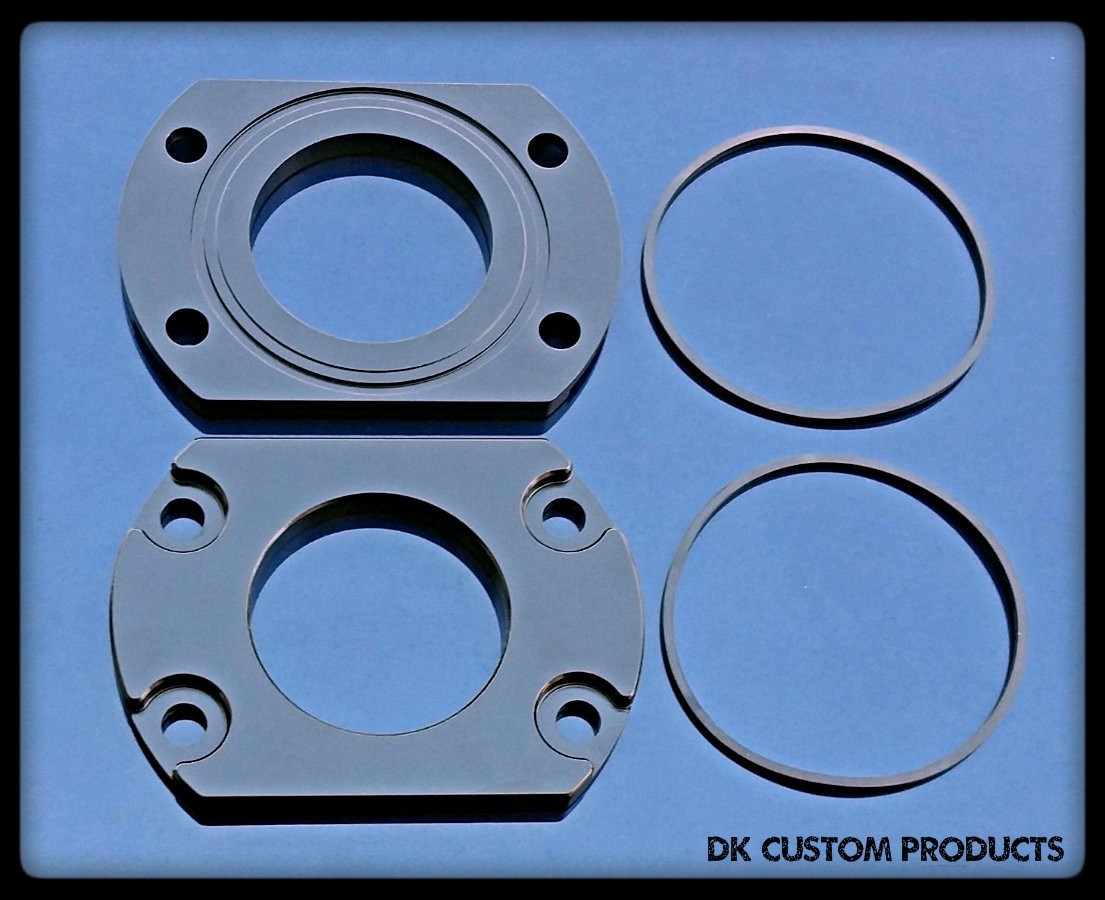

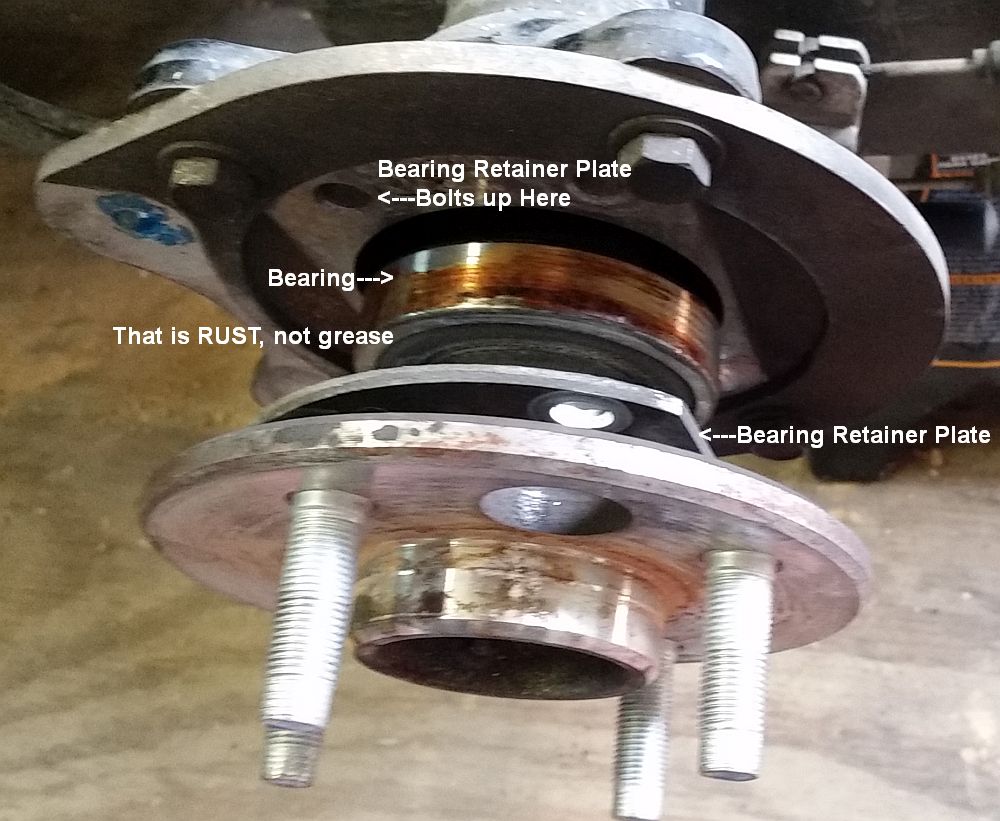

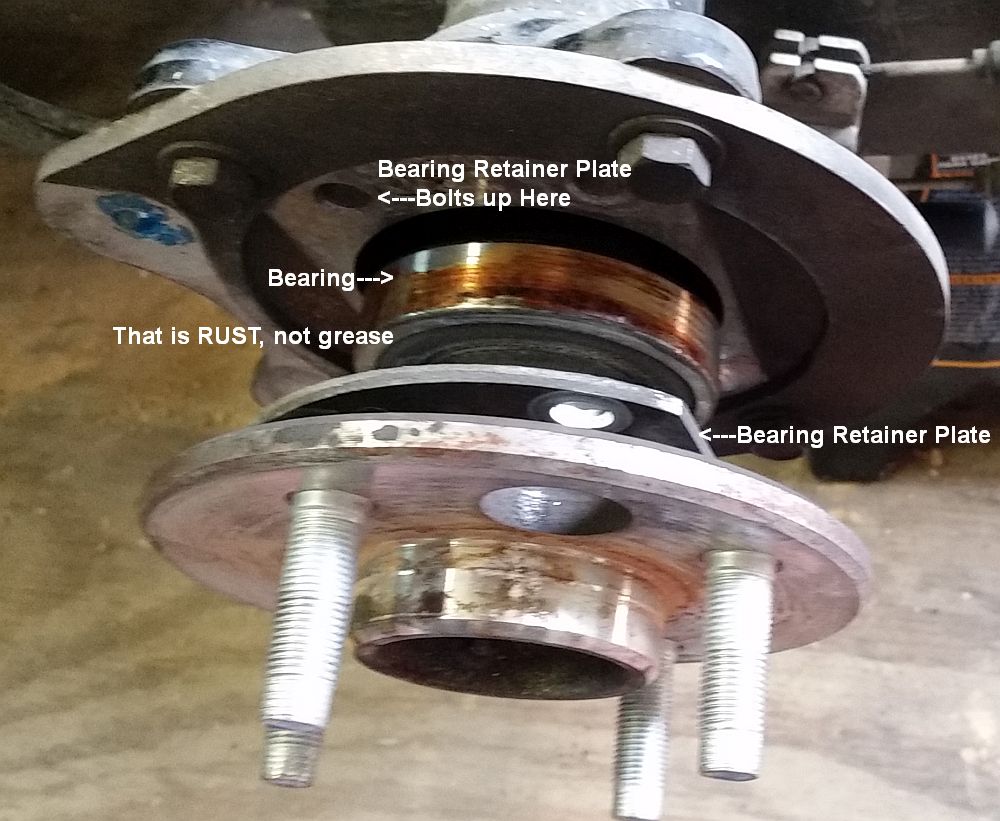

The bearing retainer plate is supposed to hold the bearing tight in the housing. It was not. Instead, the plate was allowing the bearing to rock in the housing. Below is a photo of what we saw right off the bat...

...witness marks on the plate where the bearing was banging up against it.

Here's a better photo of both plates, where the witness marks are clearly visible.

What may be even more disconcerting is how much the outer surface of the bearings were banged up from all the movement in the axle housing.

What is supposed to happen is that the bearing fits snugly in the axle housing, and then the bearing retainer plate is supposed to tighten up against the outer bearing surface and hold the bearing immobile in the housing.

Instead, because of loose HD tolerances, AND because the bearing retainer plate is a stamped material, AND too thin, it loses (or never had) it's completely flat surface. The result is that there is space between the outer bearing surface and the retainer plate.

This allows the bearing to move inside the axle housing, resulting in:

1. Banging up the bearing

2. Banging up/wearing the inner diameter of the axle housing

3. Back & forth Tire/wheel movement, which results in clicking, clanking and #4 below

4. Since the wheel end of the axle has rocking movement, that means the far end of the axle (which sits in the differential) has even more up and down movement. This results in worn splines, or worse!

Photo of axle housing worn because of bearing movement-

Photo of worn splines...

...these are not horrible, because I caught it early enough.

The last thing we saw that we did not like, although it is not a potential for catastrophic failure like the above, is that there is not a good seal to keep water out of the axle housing.

As seen in this photo, water can just sit in the axle housing and start rusting-

After discovering the above, I went out and spent some time grabbing some rear tires of different HD Trikes and seeing if there was rocking movement in them.

2 brand new ones has no movement

1 with around 5K miles had no movement

1 with around 3K miles has just a little bit of movement

3 others, ranging between 12K and 35K miles all had movement similar to mine (which has 50K miles).

Since I am leaving on a long trip shortly, I did not want to just put it back together and hope I did not have a problem while out on the road.

I also did not want to just replace the bearing retainer plates with some new ones...obviously it would happen again, and probably faster, since the axle housing is a bit beat up/misshapened.

The next post outlines what we did-

Kevin

It was less than before replacing the heim joints, but there was still a significant amount of movement and audible clicking/clanking.

We thought it must be the rear axle bearings going bad. So we removed the rear axle, and boy what a surprise!

The bearing was not bad, no play in it, and no grease leaking out of the sealed bearing.

What we did discover is that the entire bearing was rocking back and forth in the axle housing.

The bearing retainer plate is supposed to hold the bearing tight in the housing. It was not. Instead, the plate was allowing the bearing to rock in the housing. Below is a photo of what we saw right off the bat...

...witness marks on the plate where the bearing was banging up against it.

Here's a better photo of both plates, where the witness marks are clearly visible.

What may be even more disconcerting is how much the outer surface of the bearings were banged up from all the movement in the axle housing.

What is supposed to happen is that the bearing fits snugly in the axle housing, and then the bearing retainer plate is supposed to tighten up against the outer bearing surface and hold the bearing immobile in the housing.

Instead, because of loose HD tolerances, AND because the bearing retainer plate is a stamped material, AND too thin, it loses (or never had) it's completely flat surface. The result is that there is space between the outer bearing surface and the retainer plate.

This allows the bearing to move inside the axle housing, resulting in:

1. Banging up the bearing

2. Banging up/wearing the inner diameter of the axle housing

3. Back & forth Tire/wheel movement, which results in clicking, clanking and #4 below

4. Since the wheel end of the axle has rocking movement, that means the far end of the axle (which sits in the differential) has even more up and down movement. This results in worn splines, or worse!

Photo of axle housing worn because of bearing movement-

Photo of worn splines...

...these are not horrible, because I caught it early enough.

The last thing we saw that we did not like, although it is not a potential for catastrophic failure like the above, is that there is not a good seal to keep water out of the axle housing.

As seen in this photo, water can just sit in the axle housing and start rusting-

After discovering the above, I went out and spent some time grabbing some rear tires of different HD Trikes and seeing if there was rocking movement in them.

2 brand new ones has no movement

1 with around 5K miles had no movement

1 with around 3K miles has just a little bit of movement

3 others, ranging between 12K and 35K miles all had movement similar to mine (which has 50K miles).

Since I am leaving on a long trip shortly, I did not want to just put it back together and hope I did not have a problem while out on the road.

I also did not want to just replace the bearing retainer plates with some new ones...obviously it would happen again, and probably faster, since the axle housing is a bit beat up/misshapened.

The next post outlines what we did-

Kevin