grandpanystrom61

New member

Good morning to everyone, well I got my brake stay back from the machine shop. Not a happy camper about it.

Took it in looking like this

and after getting home I noticed like 4 deep dimples, took it as marks from a vice.

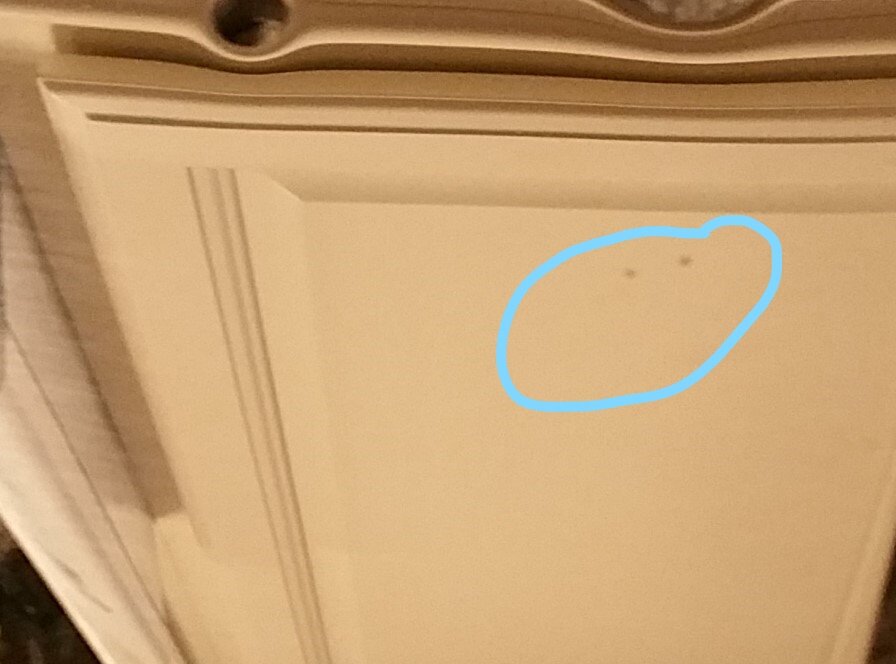

Now it was shinny, but I have spent 2 hours or more with the sander and 50grit paper and they are not as deep now and I have only these two dimples on the surface now, bummer I still can see the other two shallower ones, but they will work out.

They are a bit dark because of not being rinsed off good, but do I keep at it and get them worked out or just a bit less deep, or do I just finish the working process to the 2000 grit finish and polish it out ?

I do not see a scratch polish filler helping them, not at this depth, or does one do a spot fill weld and work out the piece out than ?

Am I being over critical about it ?

Took it in looking like this

and after getting home I noticed like 4 deep dimples, took it as marks from a vice.

Now it was shinny, but I have spent 2 hours or more with the sander and 50grit paper and they are not as deep now and I have only these two dimples on the surface now, bummer I still can see the other two shallower ones, but they will work out.

They are a bit dark because of not being rinsed off good, but do I keep at it and get them worked out or just a bit less deep, or do I just finish the working process to the 2000 grit finish and polish it out ?

I do not see a scratch polish filler helping them, not at this depth, or does one do a spot fill weld and work out the piece out than ?

Am I being over critical about it ?