irondad01

150+ Posts

- Thread starter

- #41

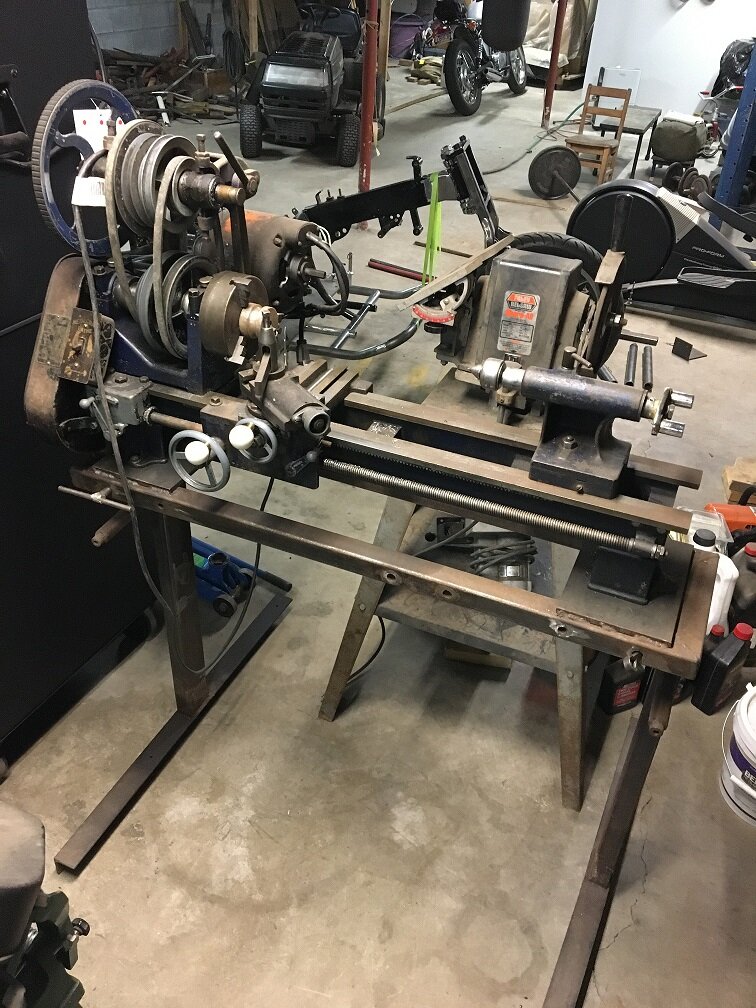

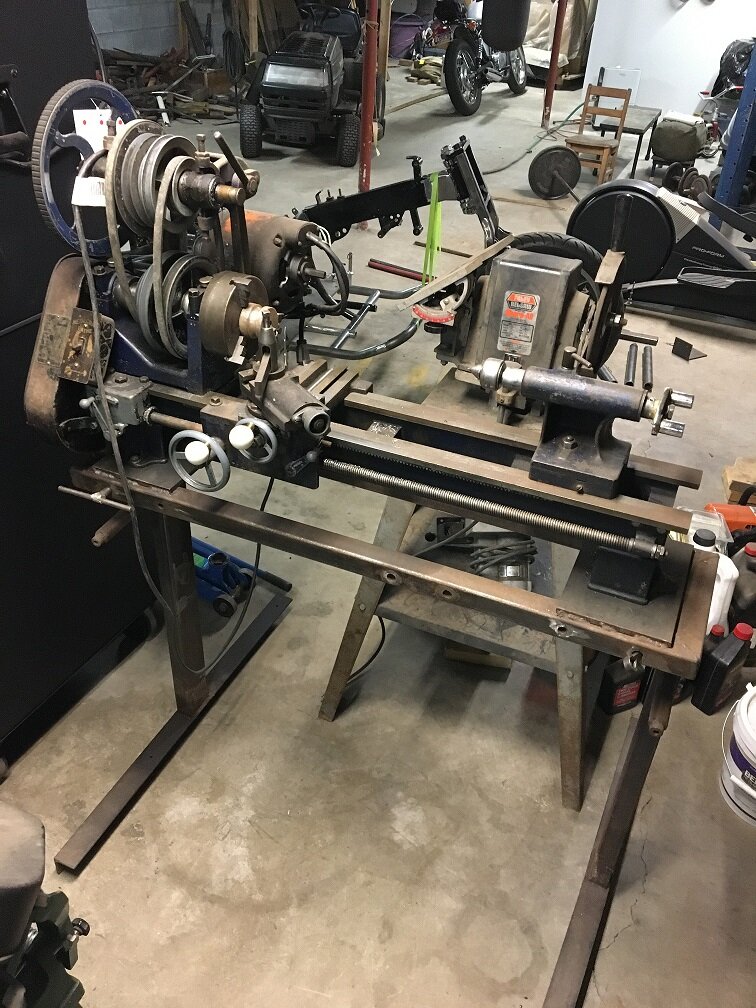

The belt driven contraption is an old lathe a friend gave me. It was all in pieces and I had to figure out how it went together. It works pretty good for what I need. The thing behind it is a saw blade sharpener that belonged to my Dad. I'd like to make a disc sander out of it.

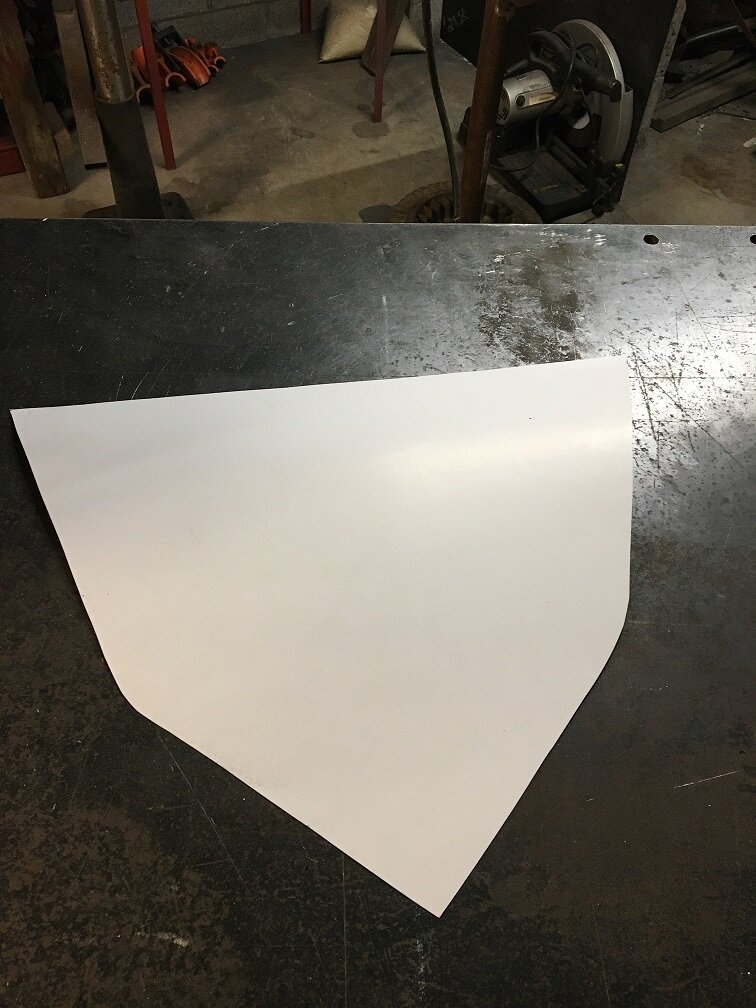

This is my setup for cutting fish mouths in the tube.

I'm going to have 2 down tubes on the front. I'll try to get that done tomorrow.

This is my setup for cutting fish mouths in the tube.

I'm going to have 2 down tubes on the front. I'll try to get that done tomorrow.