Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rear Differential

- Thread starter irondog

- Start date

One thing to take a look at is to check the bolts that affix the pulley to the differential housing and see if they are backing out, I've seen this before on the older models. You can grab the rear of the pulley itself and give it a firm back and forth shake and see if there is any play in it.

irondog

New member

- Thread starter

- #3

One thing to take a look at is to check the bolts that affix the pulley to the differential housing and see if they are backing out, I've seen this before on the older models. You can grab the rear of the pulley itself and give it a firm back and forth shake and see if there is any play in it.

Thanks, Papa....I will check that out.

FuzzyWuzHe

New member

Maybe check the wheel bearings as well.

irondog

New member

- Thread starter

- #5

Maybe check the wheel bearings as well.

It was an axle housing bearing between the belt sprocket and the differential . Ball bearings fell out on the floor it was so far gone. The clunk noise was the bolt heads holding the belt sprocket hitting the inner axle housing when turning. I now know EVERYTHING about my trike. Ken

It was an axle housing bearing between the belt sprocket and the differential . Ball bearings fell out on the floor it was so far gone. The clunk noise was the bolt heads holding the belt sprocket hitting the inner axle housing when turning. I now know EVERYTHING about my trike. Ken

Had the pulley bolts themselves started backing out of the differential housing?

irondog

New member

- Thread starter

- #7

Negative, Papa. Everything was tight. Big inner axle bearing next to diff. housing was so far gone it tweaked outer bearing and allowed axle to move horizontally about 1/8" which allowed the sprocket bolt heads to contact the inner axle housing edge. Inners were $70 each, outers $22 each. Made sense to replace all with the "good ones" while in there. Spyder gears looked like new. Packed housing with heavy grease and good to go. Ken

irondog

New member

- Thread starter

- #8

Update

Just wanted to let everyone know my recent work on the trike has done well. Several thousand miles and operares perfectly. Fuzzy, you were correct on the bearings. Too bad they were such a hassle to get to, unlike car bearings. Both inner and outer were pressed on the axles up to an indent. So everything had to come apart. Suprisingly, trike

body removal/install was the easiest part...6 bolts/nuts. Found that the 2 allen head plugs on the differential are the fasteners for the internal spyder gears that the serated axle ends drive on. Shop press needed for removal and install of bearings.

Sorry we had to miss the ride this spring... knee was giving me hell.

Hope all had a great time with no problems. Missed seeing everyone. Ken

Just wanted to let everyone know my recent work on the trike has done well. Several thousand miles and operares perfectly. Fuzzy, you were correct on the bearings. Too bad they were such a hassle to get to, unlike car bearings. Both inner and outer were pressed on the axles up to an indent. So everything had to come apart. Suprisingly, trike

body removal/install was the easiest part...6 bolts/nuts. Found that the 2 allen head plugs on the differential are the fasteners for the internal spyder gears that the serated axle ends drive on. Shop press needed for removal and install of bearings.

Sorry we had to miss the ride this spring... knee was giving me hell.

Hope all had a great time with no problems. Missed seeing everyone. Ken

Street

New member

Just wanted to let everyone know my recent work on the trike has done well. Several thousand miles and operares perfectly. Fuzzy, you were correct on the bearings. Too bad they were such a hassle to get to, unlike car bearings. Both inner and outer were pressed on the axles up to an indent. So everything had to come apart. Suprisingly, trike

body removal/install was the easiest part...6 bolts/nuts. Found that the 2 allen head plugs on the differential are the fasteners for the internal spyder gears that the serated axle ends drive on. Shop press needed for removal and install of bearings.

Hey Ken,

Glad you were able to get your bearings replaced.

I'm new here and currently working on a new to us Champion unit on a Roadstar 1700 that has developed a bearing noise in the rear axle area. It sounds like one of the large inner bearings, but plan on replacing all of them while it is apart.

I'm having trouble getting the big 3/4" allen head plugs out of the differential. They seem very tight (as all bolts have been on this kit) and I don't want to damage anything in the process. Currently flexing the 6" extension while using a 1/2" drive breakover bar with an allen socket on it. Wondering if you had any similar issues and any advice you might offer would be appreciated.

Thanks in advance.

John

Tynker

New member

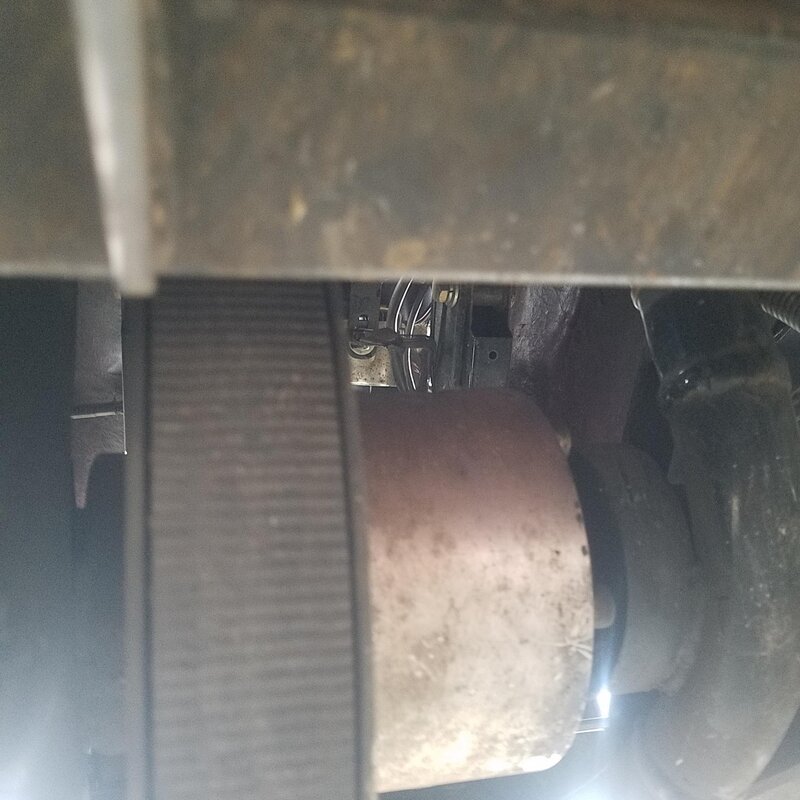

View attachment 90721

These are photos of the rear end on my 98 Ultra classic. Have no idea of the kit year. Am having something between a click and a clunk per revolution below 10 mph. Need to check grease. It has 2 opposing hex plugs, looks like 3/4" hex key size. Any info or advise greatly appreciated. Ken

Check for a rock in the belt. It will make the sound you describe,

Jack Klarich

18000+ Posts

Hey Ken,

Glad you were able to get your bearings replaced.

I'm new here and currently working on a new to us Champion unit on a Roadstar 1700 that has developed a bearing noise in the rear axle area. It sounds like one of the large inner bearings, but plan on replacing all of them while it is apart.

I'm having trouble getting the big 3/4" allen head plugs out of the differential. They seem very tight (as all bolts have been on this kit) and I don't want to damage anything in the process. Currently flexing the 6" extension while using a 1/2" drive breakover bar with an allen socket on it. Wondering if you had any similar issues and any advice you might offer would be appreciated.

Thanks in advance.

John

John, if you can easily get to the area around the plug, rap it a few times with a punch and hammer, also rap in the center of the plug itself. This usually helps free up the threads

Street

New member

John, if you can easily get to the area around the plug, rap it a few times with a punch and hammer, also rap in the center of the plug itself. This usually helps free up the threads

Thanks for replying!

I did tap on the plug while trying to loosen it but it didn't let go.

I'll try the punch method and see if it helps. Already broke an impact-grade extension on this.

Managed to get one of the bearing plates off using a slide hammer. That allowed me to get the bearing numbers and get them ordered. Once they arrive I'll take the whole thing to my mechanic to do on the press.

Thanks again as I'm always open to suggestions.

If anyone else has any ideas, feel free to chime in.

rhino 2

100000 + Posts

Thanks for replying!

I did tap on the plug while trying to loosen it but it didn't let go.

I'll try the punch method and see if it helps. Already broke an impact-grade extension on this.

Managed to get one of the bearing plates off using a slide hammer. That allowed me to get the bearing numbers and get them ordered. Once they arrive I'll take the whole thing to my mechanic to do on the press.

Thanks again as I'm always open to suggestions.

If anyone else has any ideas, feel free to chime in.

A hammer drill gun will usually shock stubborn treads loose with out doing any damage....[A little heat helps also if there's thread locker on it]

Street

New member

Tinker. The hex plugs don't have to be taken out. They just hold the spyder gears in. Once everything is pulled, axles,etc,you will have full access to the differential. Clean out completely and pack the diff full of gear grease. Ask me how I know. Ken

This is the path I eventually found. I did manage to get the large bearings out of the Axle Housing plates and off of the Diff. Put the new Timken bearings in and reassembled the entire rear axle only to have the high pitched squalling sound return to my frustrated ears. Ugh.

Had to take a break to put a new back tire on my Goldwing and lube the driveshaft splines, etc.

Pulled the Champion Axle apart again last evening, removed the sprocket, and opened 1 full side of the pumpkin. Left the big Allen bolts alone. Pulled the gear off the end plate and got the bearing number, and ordered a pair. It did have a slight clunk in one area so hoping this will be the last time digging into this.

If anyone is interested, I can list the bearing numbers in this unit which is from 2014. Just don't have the list in front of me right now.

Thanks for all of the help, y'all. The input is greatly appreciated!

jjvw

700+ Posts

Hey Ken,

Glad you were able to get your bearings replaced.

I'm new here and currently working on a new to us Champion unit on a Roadstar 1700 that has developed a bearing noise in the rear axle area. It sounds like one of the large inner bearings, but plan on replacing all of them while it is apart.

I'm having trouble getting the big 3/4" allen head plugs out of the differential. They seem very tight (as all bolts have been on this kit) and I don't want to damage anything in the process. Currently flexing the 6" extension while using a 1/2" drive breakover bar with an allen socket on it. Wondering if you had any similar issues and any advice you might offer would be appreciated.

Thanks in advance.

John

I haven't had to do bearings yet, my roadie's only got 100k on it, but I can give you a body tip: Once you get the hold down bolts out of the tunnel, find a thin flat wrench like a bicycle wrench and a fender washer and weld them on the bolt top. The wrench hitting the tunnel wall stops the bolt from turning! No need for a helper.

Another John

Can't have to many Jon's in a place(Giggle)

Street

New member

Bearing numbers

Good idea on the permanent backing wrench in the tunnels. I use either a ratchet and socket with another socket to hold the handle up, or a flat ratcheting wrench from HF just laying on the bolt. Just gotta go slow and it works great.

Got the bearings swapped in the pumpkin after some challenges getting them out. Then discovered one of the gears was out of round by .003". Doesn't sound like much but it's a precision ground part that's pressed into the bearing. I rigged it onto a bolt to spin it in a drill and took .001 off of it with Emory cloth. Put it all back together, dialed it all in and everything seems happy.

As promised, here's the bearing numbers for this SA unit from 2014. I used all Timken bearings.

Outer Axle Bearings. 6007

LG bearings connecting plates to pumpkin. 6209

Gear Bearings inside pumpkin. 6008

Thanks again for all of the input. Really appreciate this site.

Good idea on the permanent backing wrench in the tunnels. I use either a ratchet and socket with another socket to hold the handle up, or a flat ratcheting wrench from HF just laying on the bolt. Just gotta go slow and it works great.

Got the bearings swapped in the pumpkin after some challenges getting them out. Then discovered one of the gears was out of round by .003". Doesn't sound like much but it's a precision ground part that's pressed into the bearing. I rigged it onto a bolt to spin it in a drill and took .001 off of it with Emory cloth. Put it all back together, dialed it all in and everything seems happy.

As promised, here's the bearing numbers for this SA unit from 2014. I used all Timken bearings.

Outer Axle Bearings. 6007

LG bearings connecting plates to pumpkin. 6209

Gear Bearings inside pumpkin. 6008

Thanks again for all of the input. Really appreciate this site.

jjvw

700+ Posts

Good idea on the permanent backing wrench in the tunnels. I use either a ratchet and socket with another socket to hold the handle up, or a flat ratcheting wrench from HF just laying on the bolt. Just gotta go slow and it works great.

Got the bearings swapped in the pumpkin after some challenges getting them out. Then discovered one of the gears was out of round by .003". Doesn't sound like much but it's a precision ground part that's pressed into the bearing. I rigged it onto a bolt to spin it in a drill and took .001 off of it with Emory cloth. Put it all back together, dialed it all in and everything seems happy.

As promised, here's the bearing numbers for this SA unit from 2014. I used all Timken bearings.

Outer Axle Bearings. 6007

LG bearings connecting plates to pumpkin. 6209

Gear Bearings inside pumpkin. 6008

Thanks again for all of the input. Really appreciate this site.

Thanks for the bearing #s. Hope I never need them

Welcome to the Trike Talk Community

Join our vibrant online community dedicated to all things Trikes! Whether you're a seasoned rider or just starting out, this is the place to share experiences, tips, and stories about your three-wheeled adventures. Explore modifications, maintenance advice, and rides, all while connecting with fellow trike enthusiasts from around the globe

Trike Talk Community

Welcome to a community dedicated to the most diverse and fastest growing powersports segment, Motorcycle Trikes. Come join the discussion about the best makes and models, popular modifications and proven performance hacks, trike touring and travel, maintenance, meetups and more!

Register Already a member? Login