How Do You Jack Up Your No Lean Susp. Solid Axle for Tire Change?

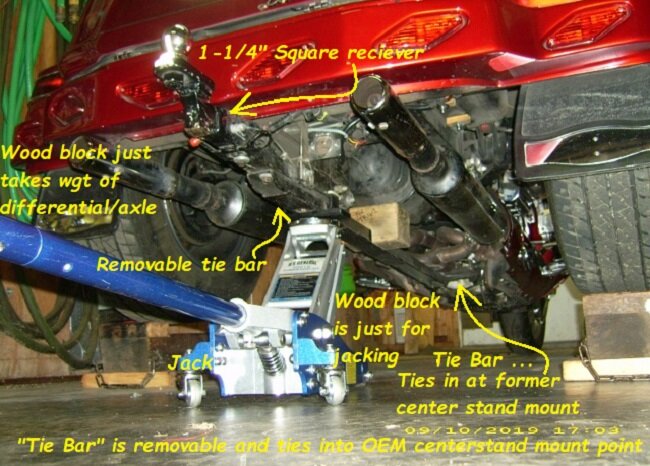

I have a 2004 Honda Goldwing GL1800 Monarch (not a Monarch ll) with running boards and the no lean suspension solid axle. I do all of my underside maintenance by backing up on ramps > when needed, I centrally jack up under my differential with a floor jack and place jack stands under the axle "at" each side differential. I was told when I had my trike built, to only jack up under the differential.

I'm whispering here; Luckily, I've never had a flat (Whew) over the past 19 years therefore, I never had to jack mine up on the roadside. I do carry a scissor jack & 4x6" block in my CSC trailer. As you know, when removing a tire from these Lehman's, you have to be raised pretty high.... and it's still a P.I.A. due to being a tight fit. Out of curiosity after all these years, I'm wondering if you owners have ever jacked up on the outer portion of the axle next to the wheel? I personally don't see a reason why you couldn't but.... there may be. Thanks. Ray

I have a 2004 Honda Goldwing GL1800 Monarch (not a Monarch ll) with running boards and the no lean suspension solid axle. I do all of my underside maintenance by backing up on ramps > when needed, I centrally jack up under my differential with a floor jack and place jack stands under the axle "at" each side differential. I was told when I had my trike built, to only jack up under the differential.

I'm whispering here; Luckily, I've never had a flat (Whew) over the past 19 years therefore, I never had to jack mine up on the roadside. I do carry a scissor jack & 4x6" block in my CSC trailer. As you know, when removing a tire from these Lehman's, you have to be raised pretty high.... and it's still a P.I.A. due to being a tight fit. Out of curiosity after all these years, I'm wondering if you owners have ever jacked up on the outer portion of the axle next to the wheel? I personally don't see a reason why you couldn't but.... there may be. Thanks. Ray