DK Custom Products

Sponsor

- Thread starter

- #81

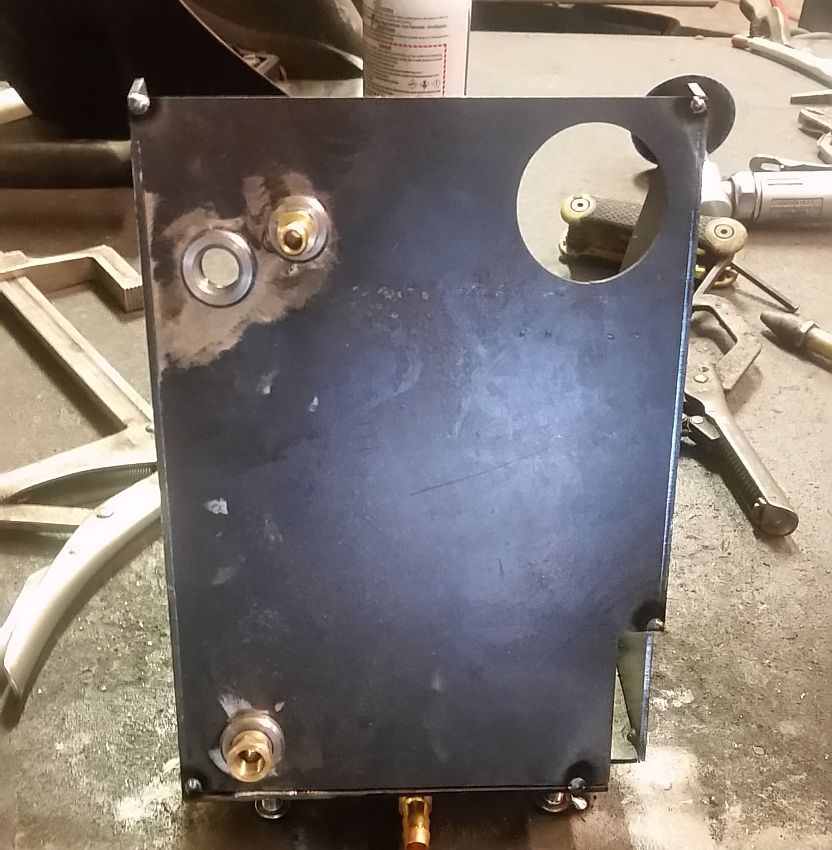

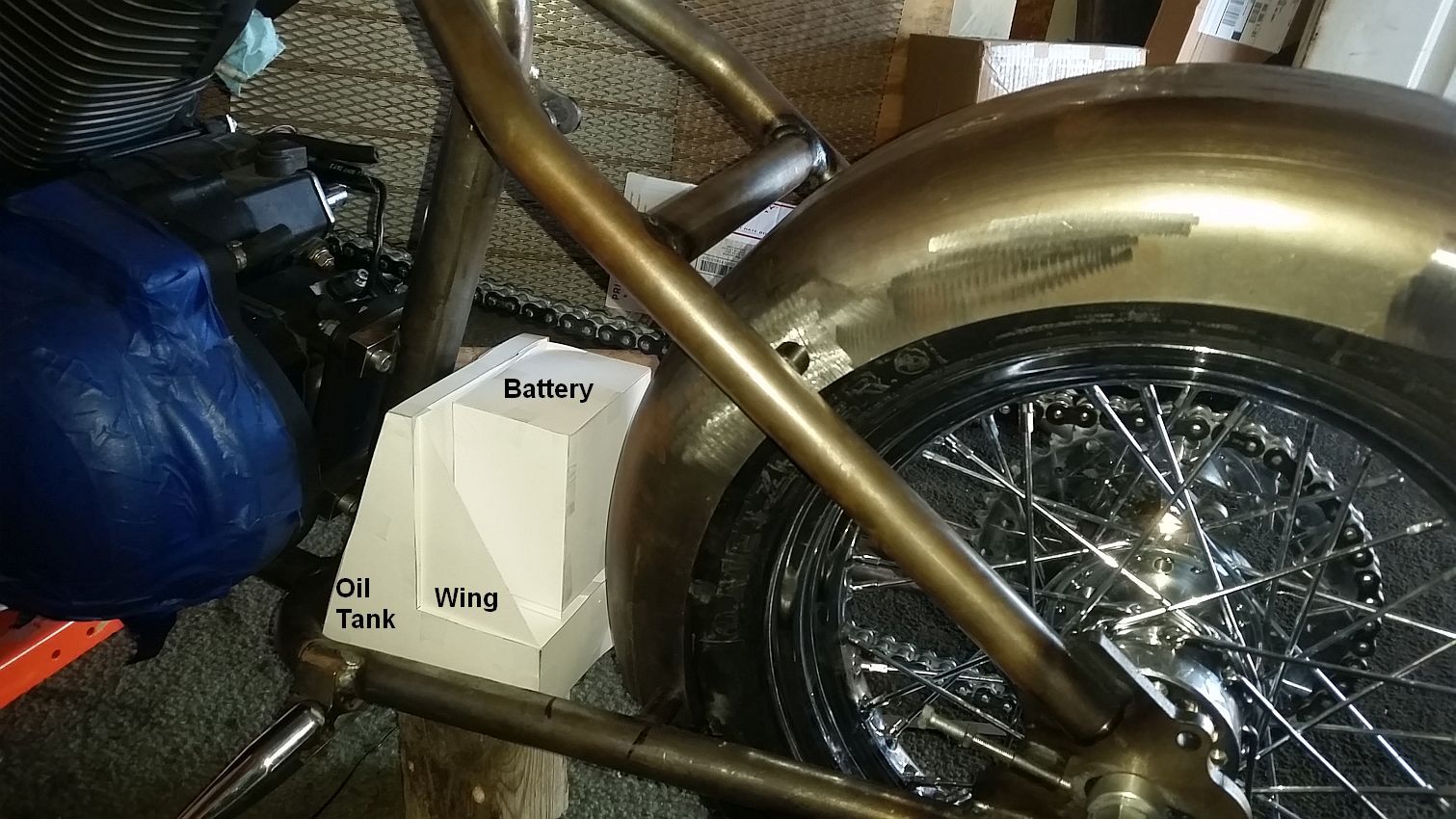

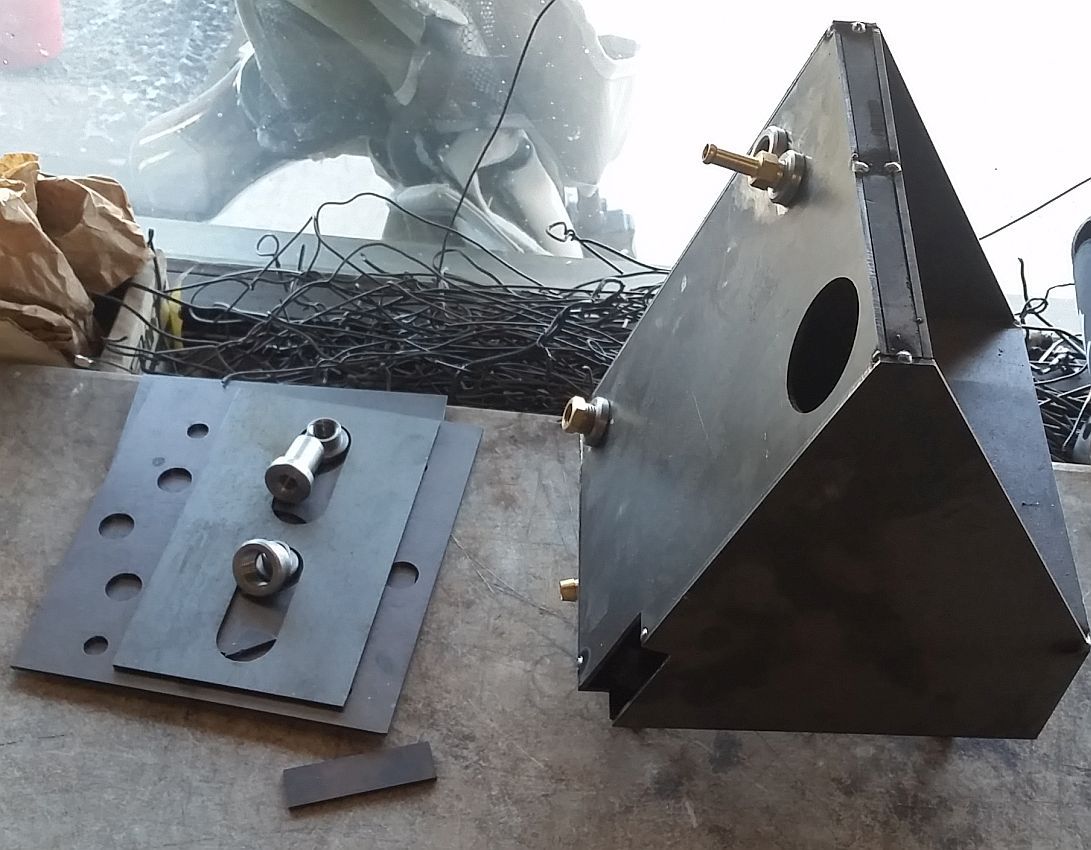

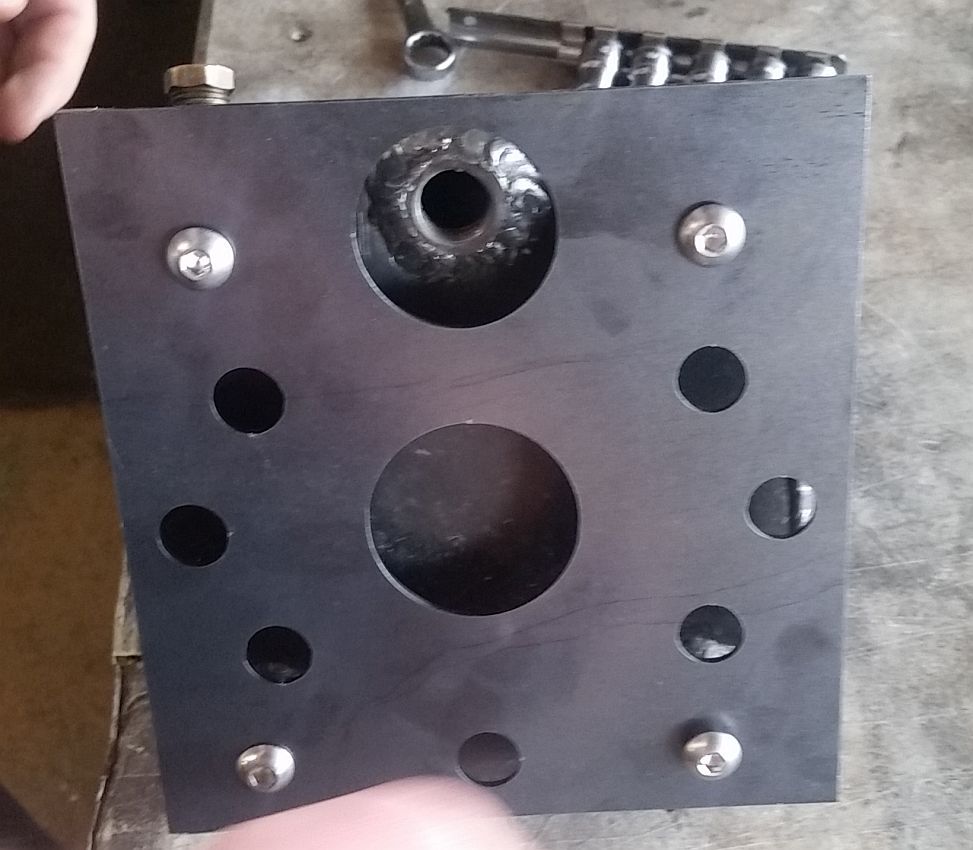

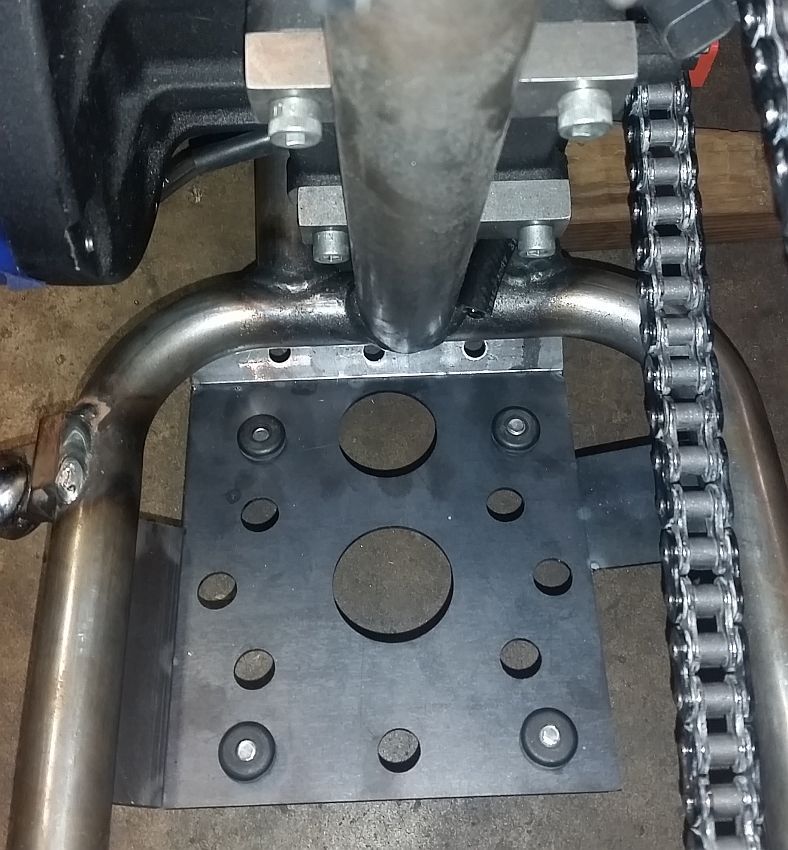

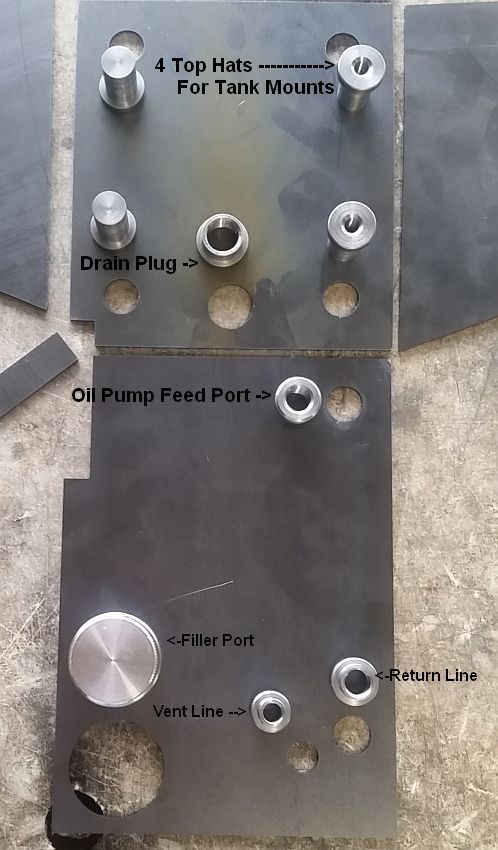

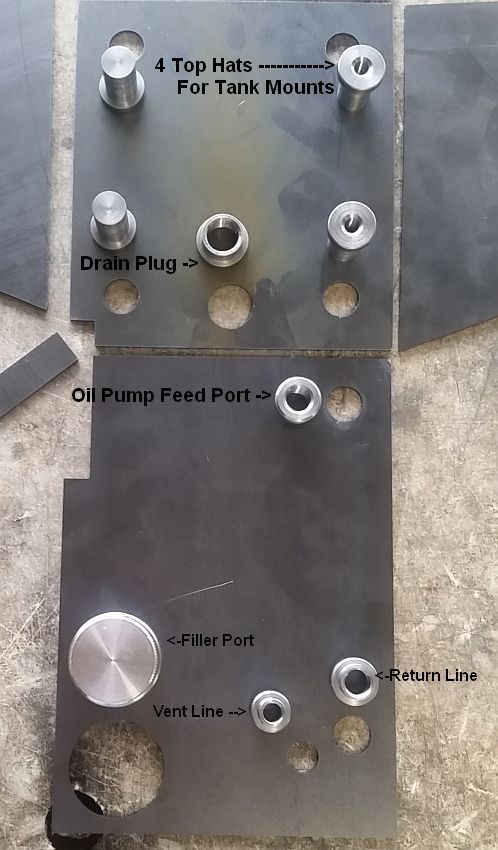

We got the tank pieces laser cut, and the bungs came in from Bung King.

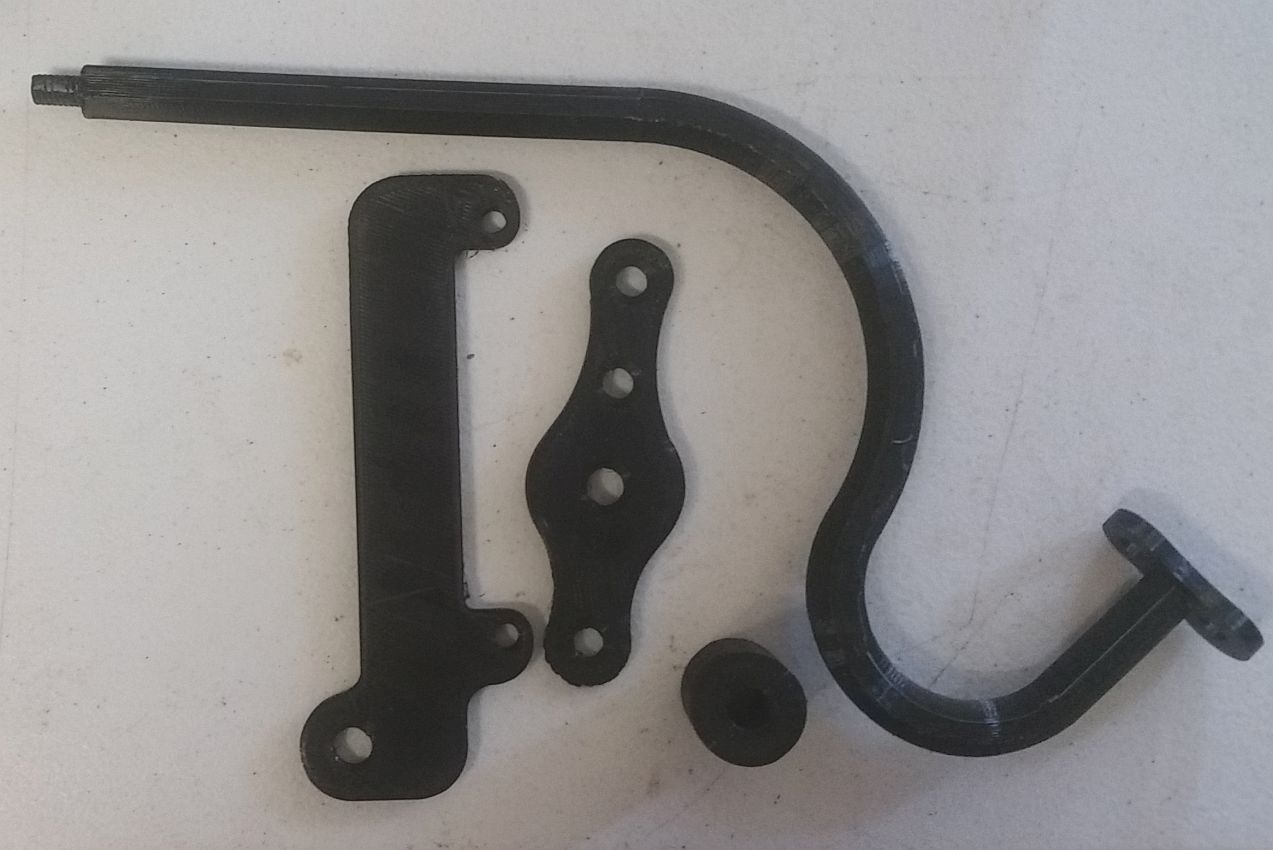

Here are all the parts laid out...

...what goes where.

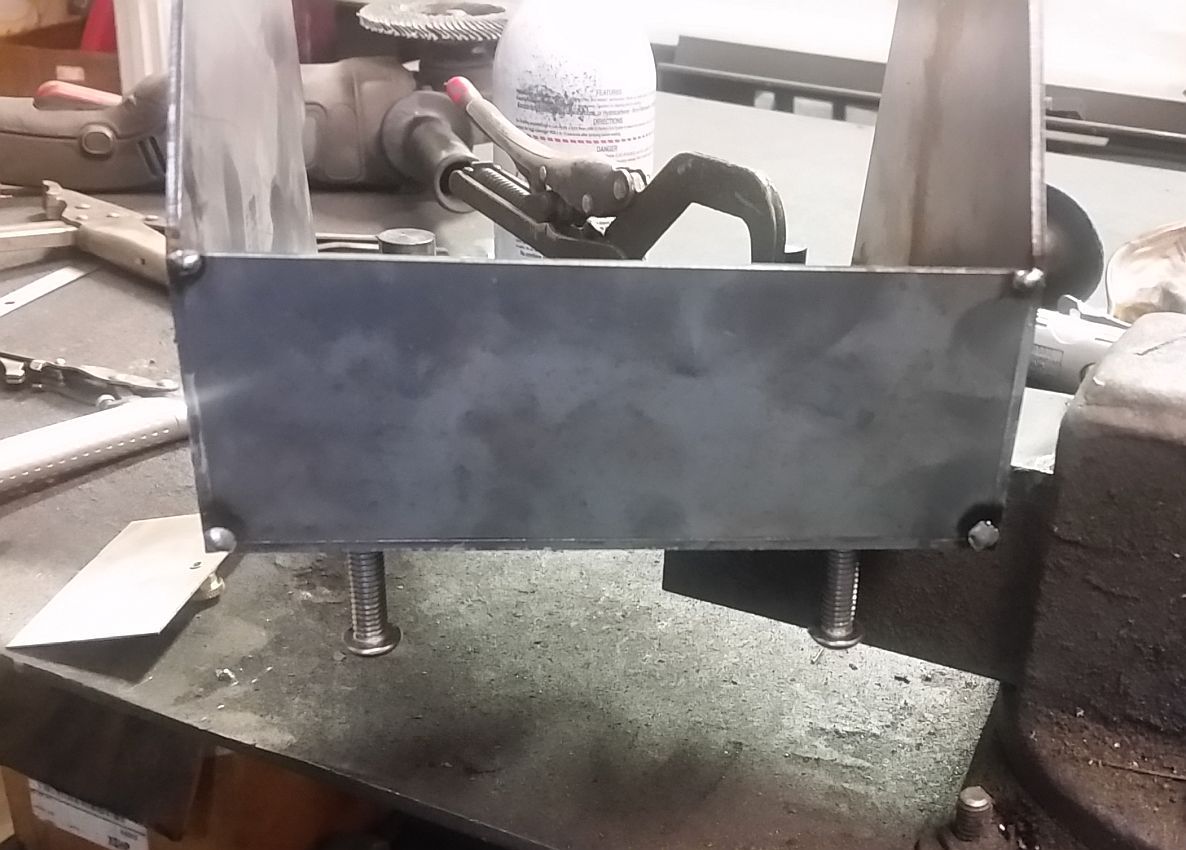

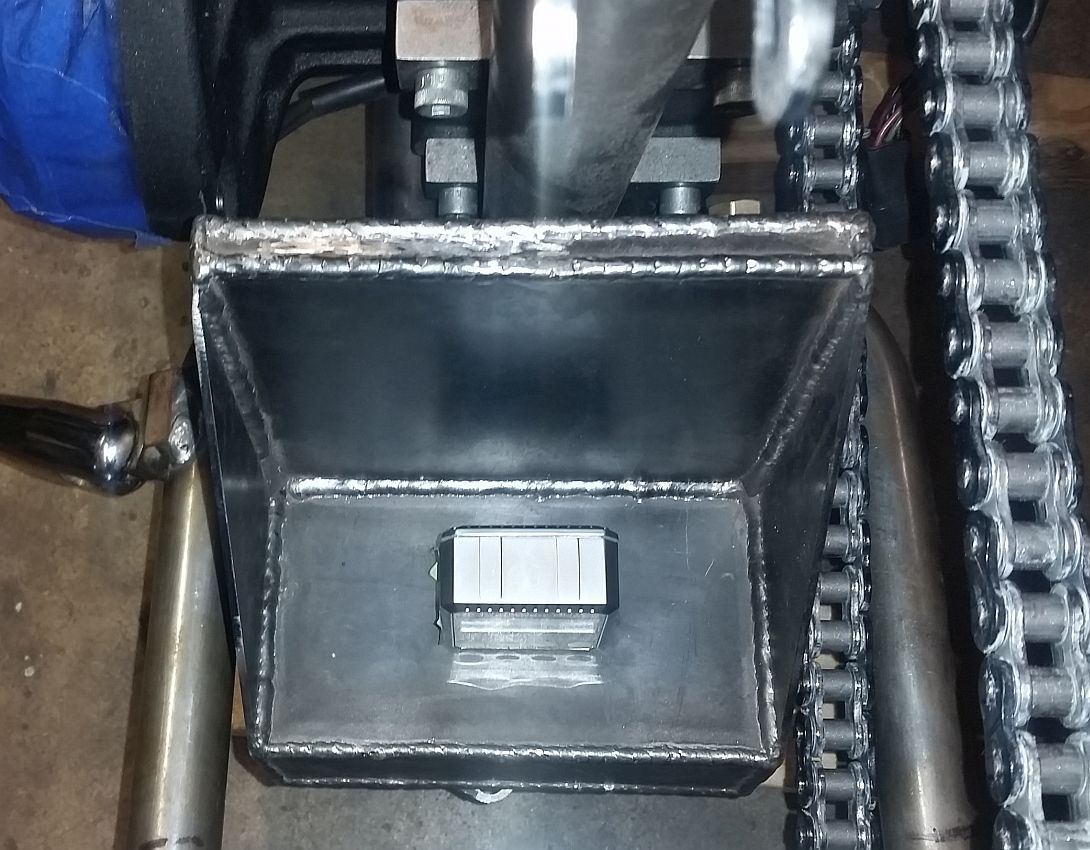

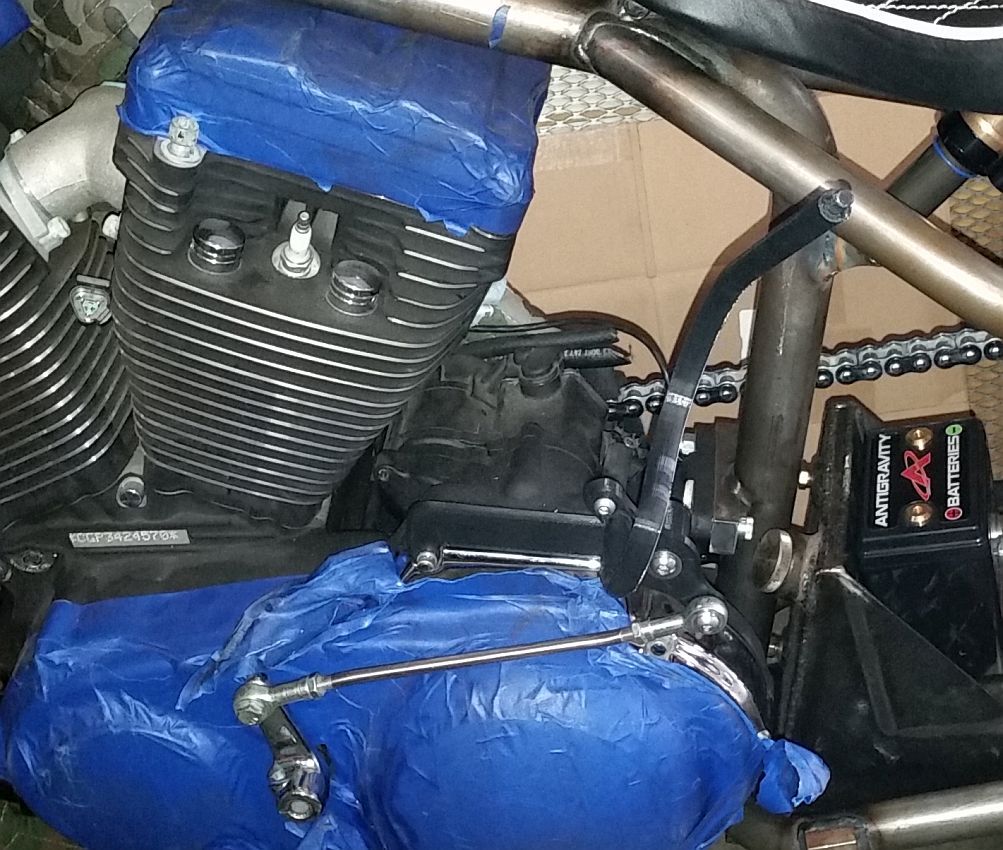

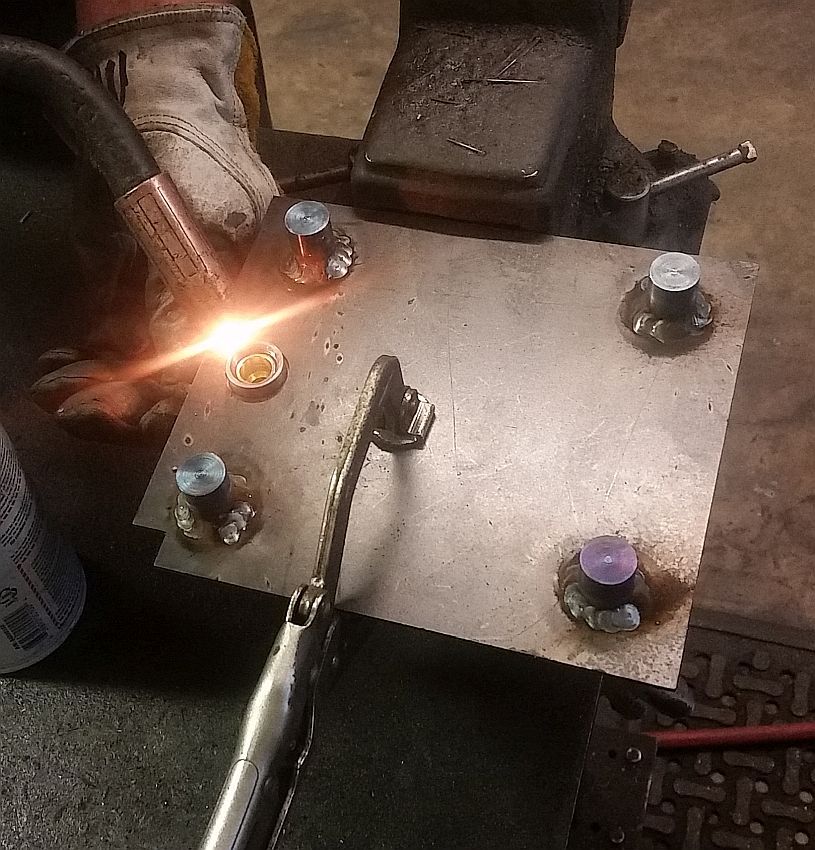

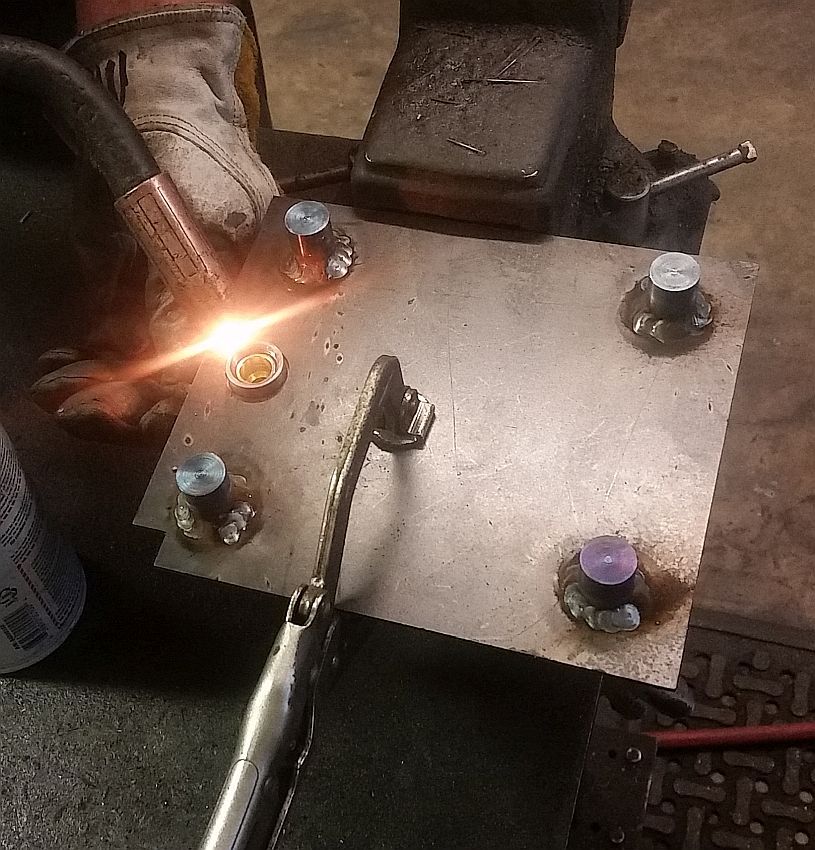

Today we are just going to tack everything together, making sure it all fits.

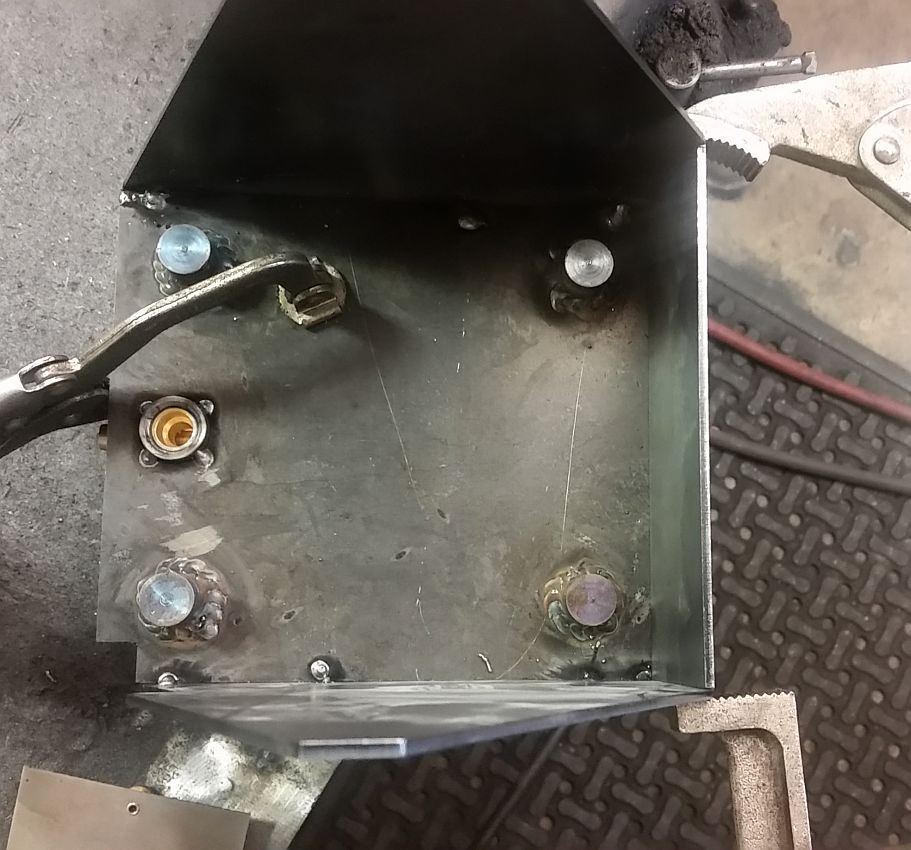

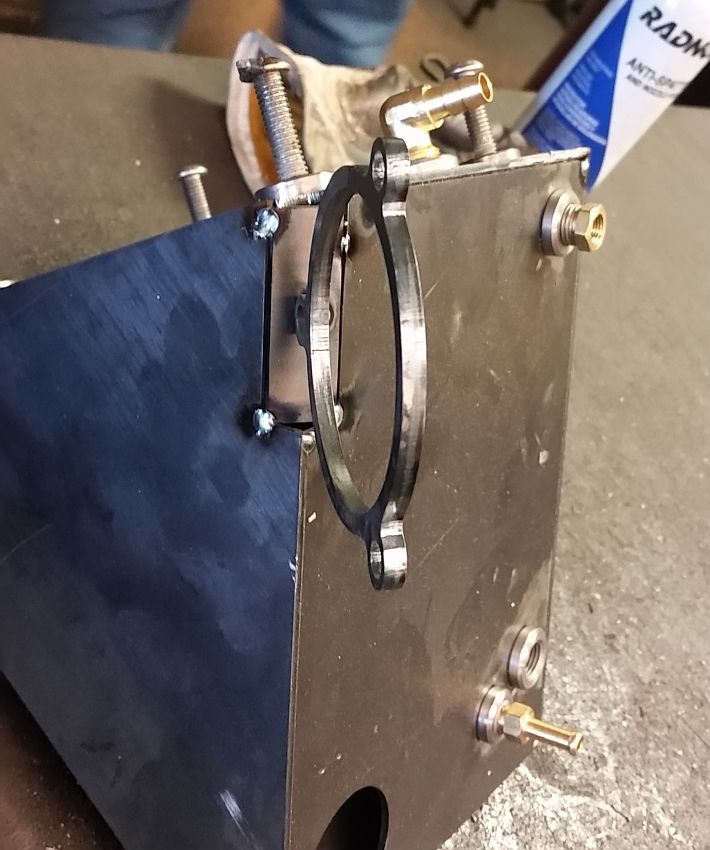

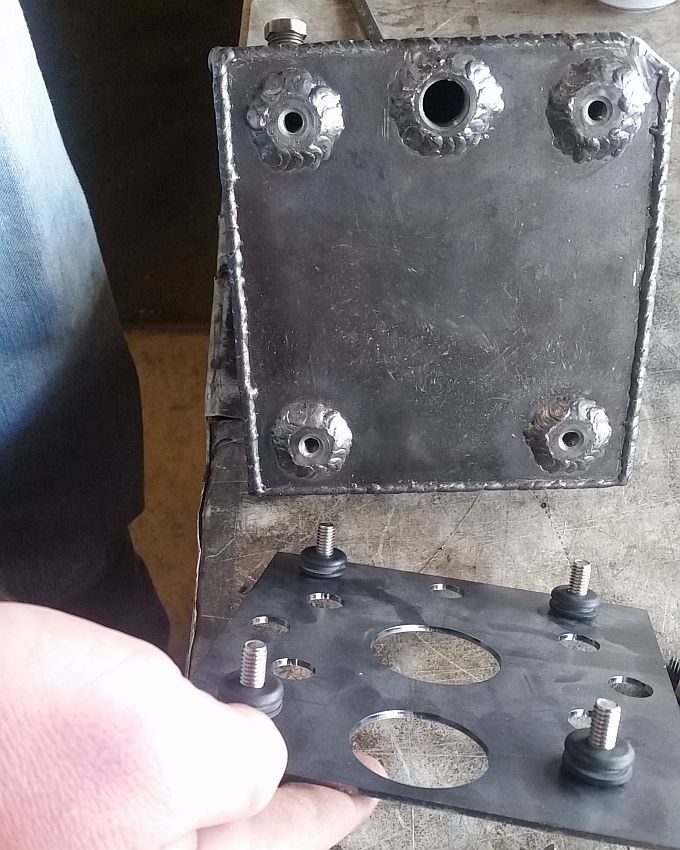

Before starting we coated the threads in anti-sieze and put bolts/fittings in to keep the threads from deforming while being welded.

The four tophats are the only pieces that will be fully welded on the inside. They will also be welded fully on the outside. These 4 points are where the tank will be rubber mounted to the skid plate.

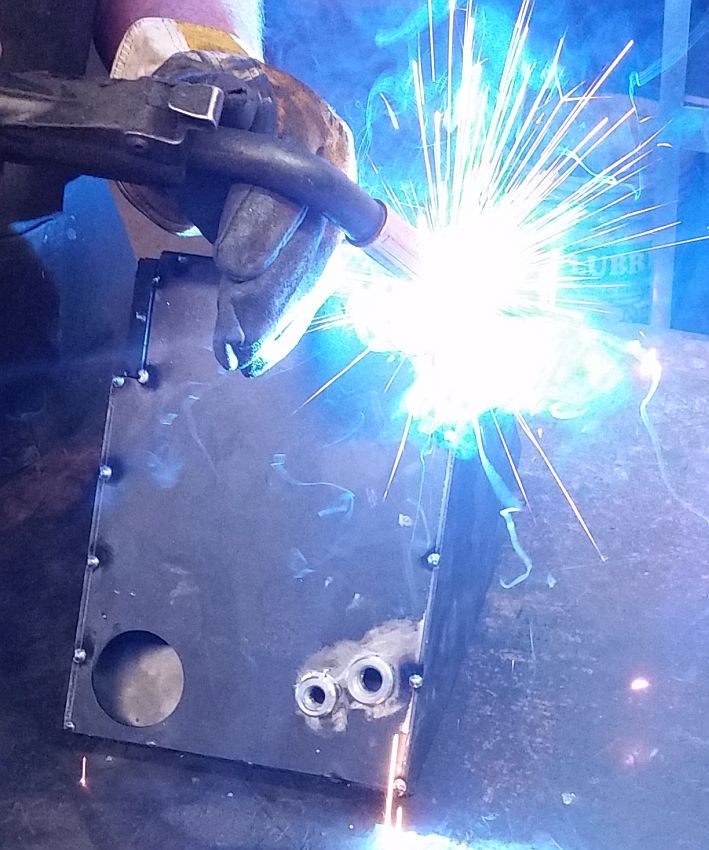

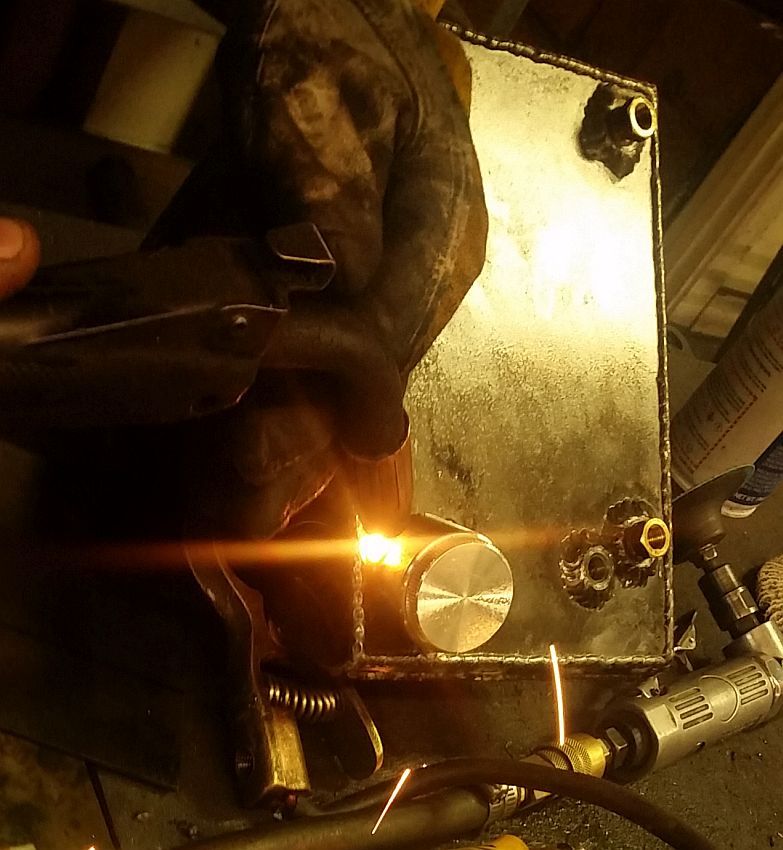

Tacking in the drain plug bung.

Don't laugh...or go ahead, it is pretty funny. The last time I welded was 42 years ago!

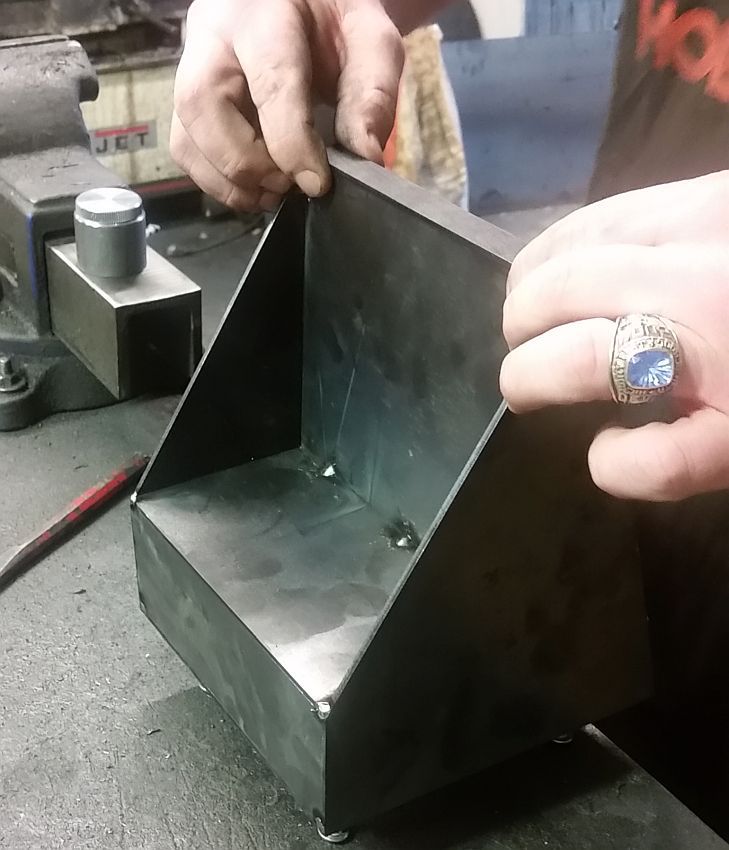

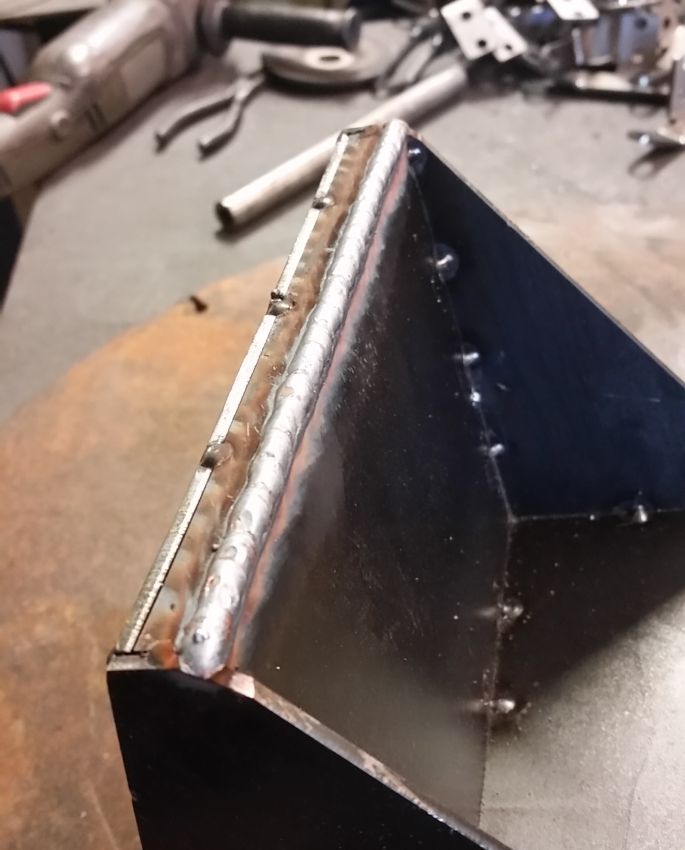

Devin held the 1st side plate in place while I tacked it. Not pretty, but it held.

btw, I've shared this before, but....

The way that DK Custom Products got started was when I (the "K" in DK) had an idea for some Custom Handlebars. I had several shops that said they would weld them up for me...NONE of them had even started them within weeks of when they said they would be finished with them.

Devin (the "D" in DK) was, at the time, engaged to my daughter. On a flyer I asked him if he could weld them up for me. He said sure...AND, he had them done pretty quickly!

I had a few other ideas for parts...he made them up. Then other folks started asking for parts, and it grew from there.

More on the oil tank in next post.

Here are all the parts laid out...

...what goes where.

Today we are just going to tack everything together, making sure it all fits.

Before starting we coated the threads in anti-sieze and put bolts/fittings in to keep the threads from deforming while being welded.

The four tophats are the only pieces that will be fully welded on the inside. They will also be welded fully on the outside. These 4 points are where the tank will be rubber mounted to the skid plate.

Tacking in the drain plug bung.

Don't laugh...or go ahead, it is pretty funny. The last time I welded was 42 years ago!

Devin held the 1st side plate in place while I tacked it. Not pretty, but it held.

btw, I've shared this before, but....

The way that DK Custom Products got started was when I (the "K" in DK) had an idea for some Custom Handlebars. I had several shops that said they would weld them up for me...NONE of them had even started them within weeks of when they said they would be finished with them.

Devin (the "D" in DK) was, at the time, engaged to my daughter. On a flyer I asked him if he could weld them up for me. He said sure...AND, he had them done pretty quickly!

I had a few other ideas for parts...he made them up. Then other folks started asking for parts, and it grew from there.

More on the oil tank in next post.