- Thread starter

- #21

I try to bleed the system last night, by removing the Slave and putting it below the M.C . then pushing the and puling the push rod on the slave, forcing any possible air out the M.C. I got air out, but it just kept coming... little bubbles, then bigger ones... so I changed the fitting going in to the slave,( it looked suspicious to me) wit a banjo type fitting... bled it again, -and again, the bubbles kept coming.

so i suspect the M.C. may be letting air back in the system, I did not detect any leaking anywhere...I never took a M.C.apart, but it can't be to hard.. .. I'll do it this weekend.

.. I'll do it this weekend.

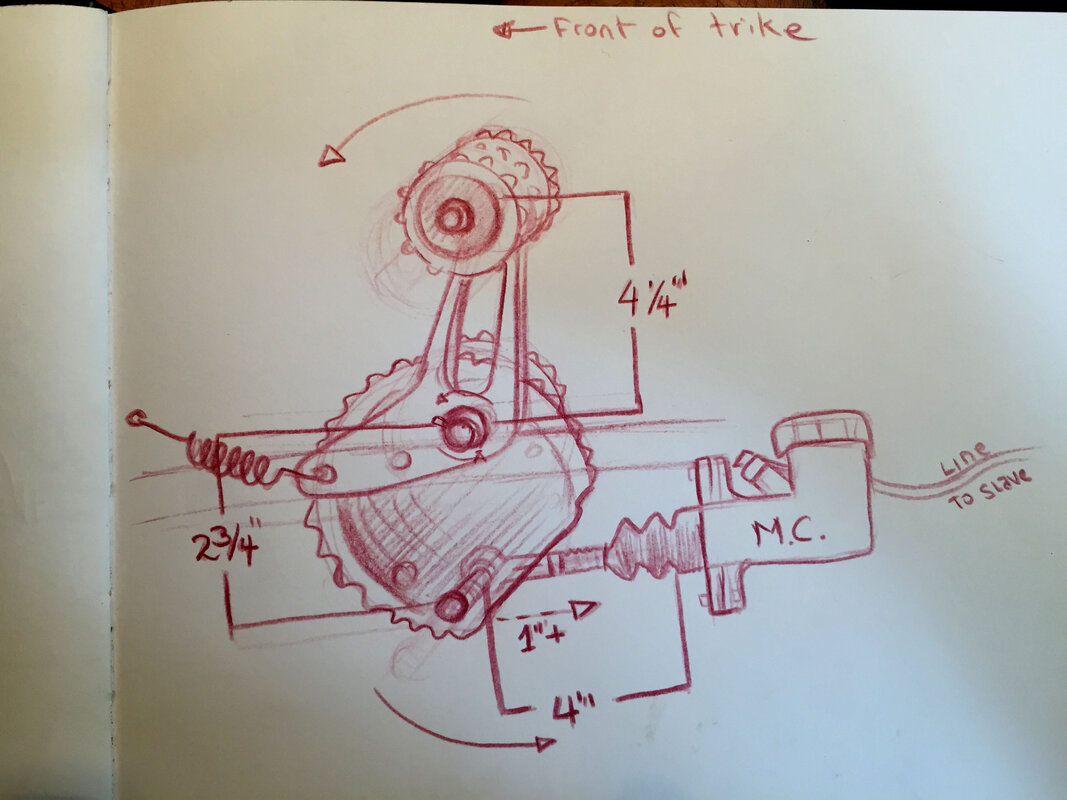

-now the pedal may also be a problem, but it does let me push the M.C. rod all the way in and out ... with that said,I apologize for my ignorance... but, I don't really understand what 7 to 1 mean. so is my pedal to short? do you guys have any diagrams/drawings or photos of a good pedal build... I would re build my pedals if necessary, but before I do that, i would like to have a good understanding of it .

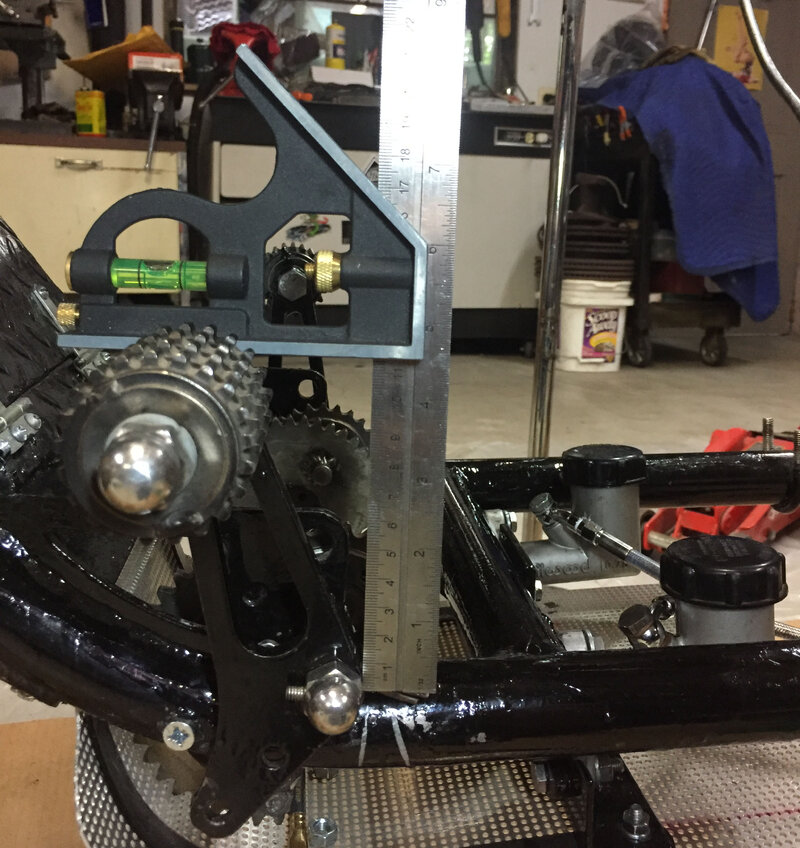

I will attach some pics and a drawing of my pedal assembly.

thank you for all the help !!

so i suspect the M.C. may be letting air back in the system, I did not detect any leaking anywhere...I never took a M.C.apart, but it can't be to hard..

-now the pedal may also be a problem, but it does let me push the M.C. rod all the way in and out ... with that said,I apologize for my ignorance... but, I don't really understand what 7 to 1 mean. so is my pedal to short? do you guys have any diagrams/drawings or photos of a good pedal build... I would re build my pedals if necessary, but before I do that, i would like to have a good understanding of it .

I will attach some pics and a drawing of my pedal assembly.

thank you for all the help !!