- Thread starter

- #41

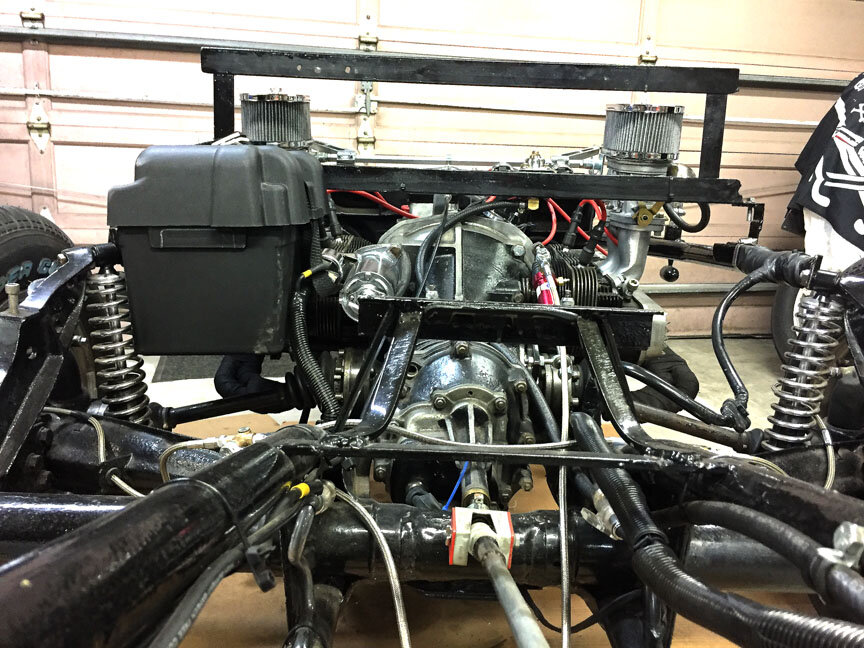

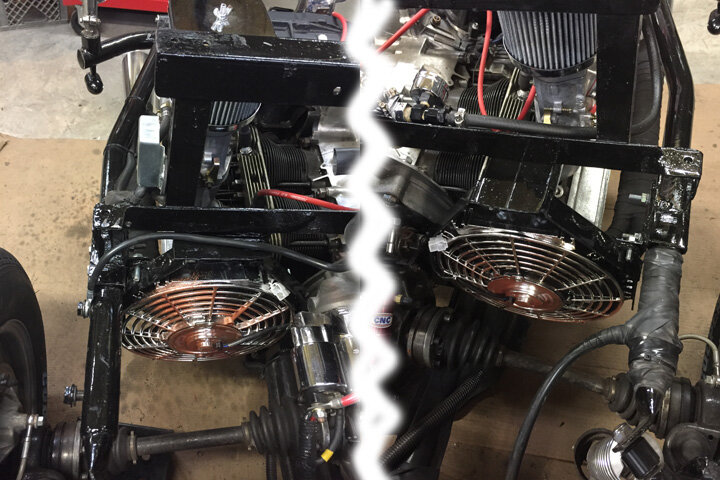

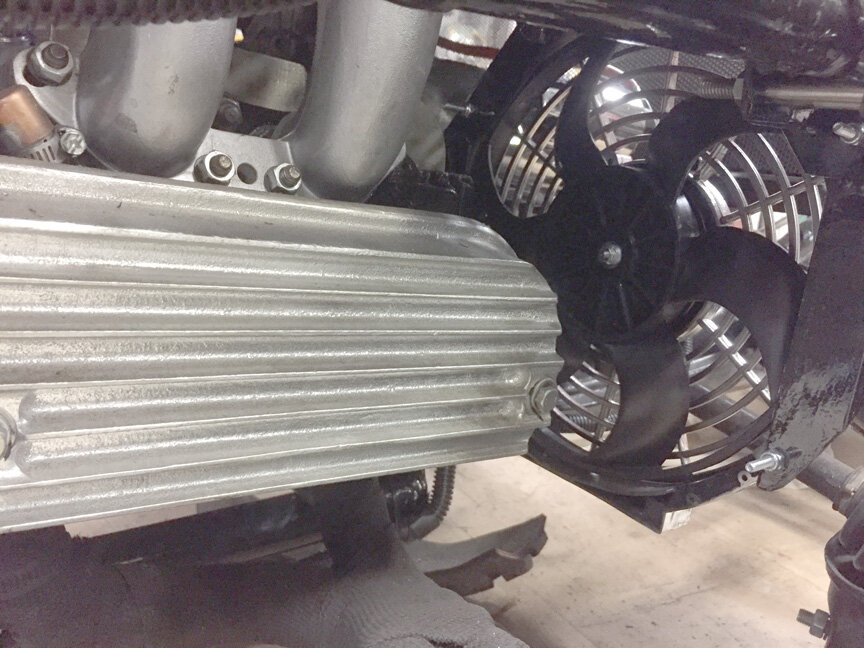

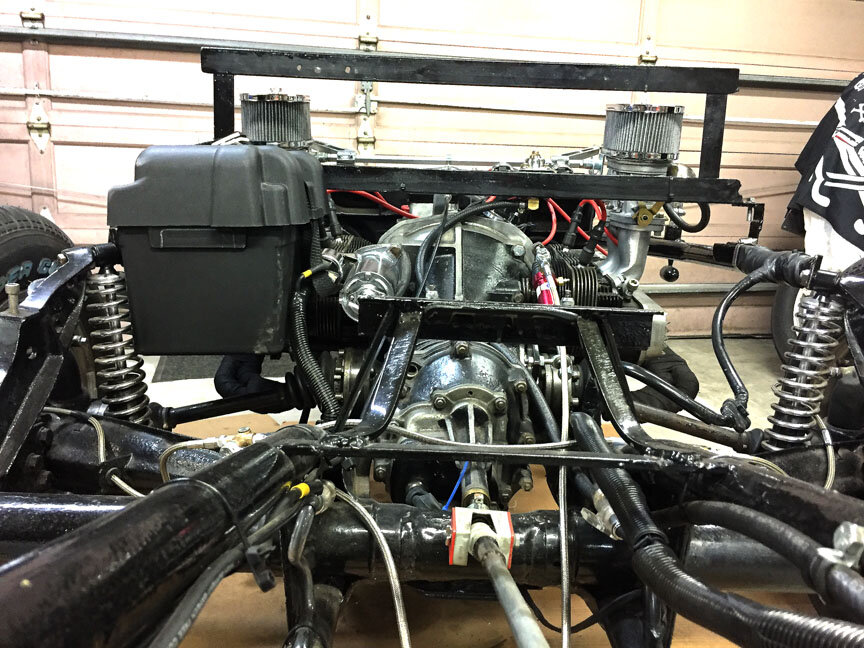

Here is what it looks like at the moment, I will be using the hood from a 1949 Chevy, so there will be a lot of space for air to flow,---

I know it's on the back of the trike...but it covers the engine... so it's a hood . Right? - I'll call it that-

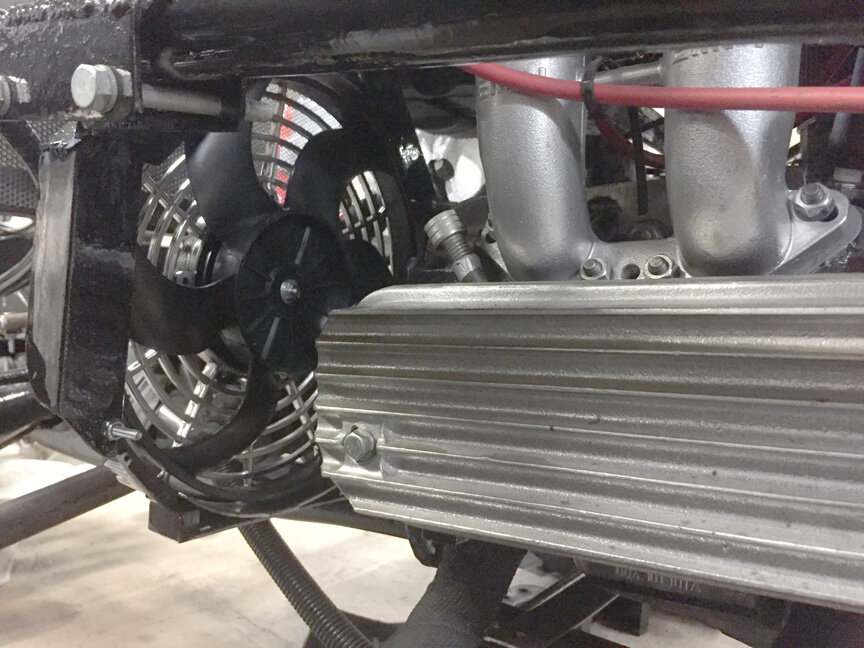

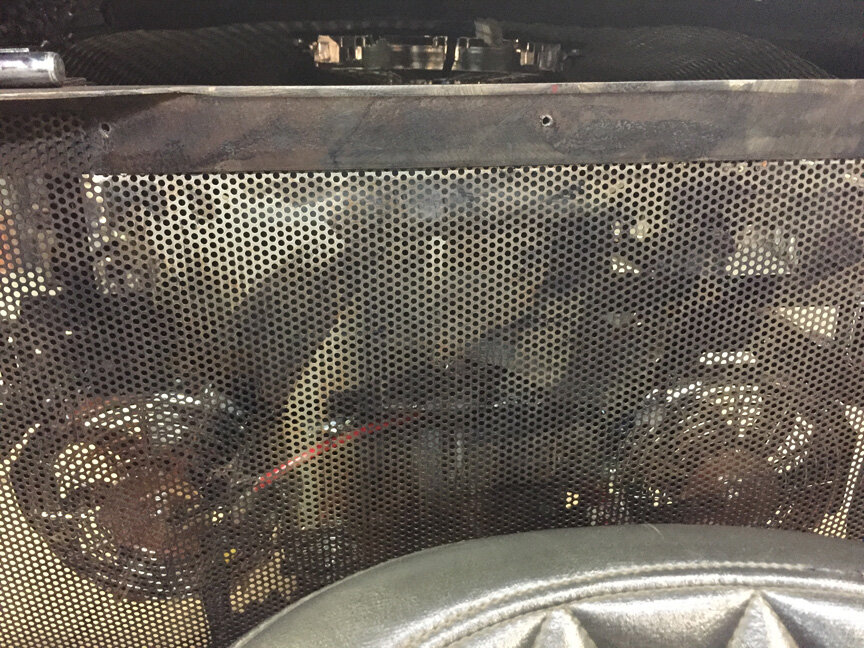

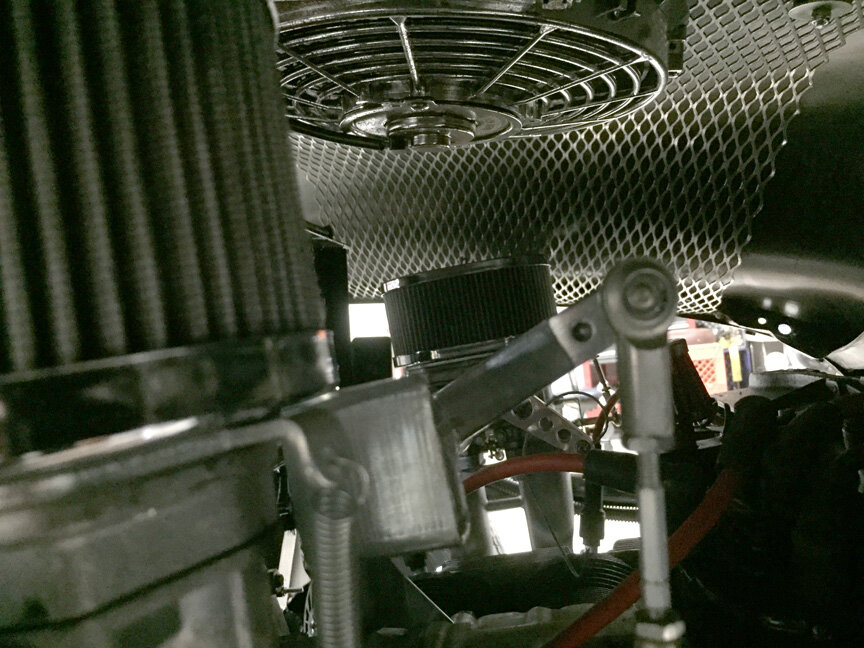

So the hood will come right to the saddle, so behind the passenger spot- there will be a pebble guard, from the hood to the deck. this will allow air to flow pass the heads and the whole engine... I will also have a pebble guard under the engine, so basically making an engine compartment that allows plenty of air flow.

was also considering making a sort of shroud to channel the incoming air stream...

I know it's on the back of the trike...but it covers the engine... so it's a hood . Right? - I'll call it that-

So the hood will come right to the saddle, so behind the passenger spot- there will be a pebble guard, from the hood to the deck. this will allow air to flow pass the heads and the whole engine... I will also have a pebble guard under the engine, so basically making an engine compartment that allows plenty of air flow.

was also considering making a sort of shroud to channel the incoming air stream...