Hi, new here, finishing up a V8 trike project. Would like to see how y'all are getting full throttle using a stock Harley twist grip. I can only get about 1/2 to 2/3 movement. Any help is appreciated.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

throttle mutiplier

- Thread starter built-it

- Start date

rhino 2

100000 + Posts

Hi, new here, finishing up a V8 trike project. Would like to see how y'all are getting full throttle using a stock Harley twist grip. I can only get about 1/2 to 2/3 movement. Any help is appreciated.

AJ Welcome to Trike-Talk........:clapping:....

paws

Just Killing Time...

Hello AJ! Just want to say WELCOME TO TRIKETALK. !!!!!

Can't help with the throttle issue, but, I'm sure one of the builders will chime in. In the meantime, Welcome to the Gang from Western Colorado.

Sully

Trike Talk Executive Chef

Welcome from North Ga. .:wave4:

vwbug72501

700+ Posts

Can you post a picture of the throttle body/carb linkage end?

Not too good with pictures, no linkage, cable is hooked to hole in carb. throttle side plate made on the throttle shaft. Need some way to multiply the cable travel. Thanks

DeathBySnuSnu

Old Redneck Motorhead

My solution would be......math.

Calculate the circumference of the arc of the spool to get the cable pull displacement.

Then back figure from there to get the arc radius need at the carb.

Needless to say.....I plan ahead a bit further.

So where you stand with trying to get what you have now to work.

The existing throttle has a certain amount of pull. As in how much cable it pulls in. So you can just unhook it from carb. Pull cable tight and measure how much cable sticks out. Then rotate to grip to full and measure again how much cable sticks out. You can then use that difference to figure lever length for carb.

Bottom line...... your cable connection point at the carb is too far away from the butterfly shaft centerline.

Move the anchor point closer to the shaft. Drill a new hole...ect. Trail and error way. Take some needle nose vice grips and clip the cable to the lever at a closer to center position......turn grip and inspect.....move vice grip and cable again.....test. Eventually you will find the spot that a full turn of the grip equals the carb full open. Mark it and make a new hole to attach the cable too.

Calculate the circumference of the arc of the spool to get the cable pull displacement.

Then back figure from there to get the arc radius need at the carb.

Needless to say.....I plan ahead a bit further.

So where you stand with trying to get what you have now to work.

The existing throttle has a certain amount of pull. As in how much cable it pulls in. So you can just unhook it from carb. Pull cable tight and measure how much cable sticks out. Then rotate to grip to full and measure again how much cable sticks out. You can then use that difference to figure lever length for carb.

Bottom line...... your cable connection point at the carb is too far away from the butterfly shaft centerline.

Move the anchor point closer to the shaft. Drill a new hole...ect. Trail and error way. Take some needle nose vice grips and clip the cable to the lever at a closer to center position......turn grip and inspect.....move vice grip and cable again.....test. Eventually you will find the spot that a full turn of the grip equals the carb full open. Mark it and make a new hole to attach the cable too.

''Needless to say.....I plan ahead a bit further.'' Ok, what would you do?

DeathBySnuSnu

Old Redneck Motorhead

I am so sorry.....

I really dont mean to sound so snide.

I apologize for that.

I am a mechanical engineer and I would have calculated it out in advance. More than likely I would have been stuck with a certain starting point. Just as an example let's say a holley carb. So I would have called the engineering dept at holley and asked for the technical details such as spring rate and lever length. If they would not release info I would then measure for myself with a strain guage and a measured lever length.

Then I would determine how much force I would be willing to continually output with my hand, either by research or by measuring. Then use those two data points to calculate how long the lever on carb would have to be to match how force is required. Now with a lever length I would calculate the stroke required to move carb it's full range. Then with a stroke length I would calculate the radius of the hand throttle spool.

Then purchase or make a hand throttle that is that dimension. If the calculated spool size is beyond reasonable size I would then look into reducing/increasing the spring weight at the carb. If a spring weight is changed you would then start all over again and go back through the calcs again to double check.

I myself would have done this before purchasing the very first part.....then once figured I would buy the carb with the known spring rate, the throttle with the known spool diameter and then manufacture the carb lever length and the cable anchor bracket. Then assemble and most likely it works the first time with the desired stroke and force desired.

There are a few details left out....for instance....the carb stroke to the spool radius will probably not be a direct 1 to 1 ratio. So most likely the will be a ratio to apply to the force calculations. But assuming a 1 to 1 gets the starting point and you must figure from there.

And......yes......I have done this.....even on my own trike.

But like I said.....in the end of it all you already have certain parts that you want to make work. Bottom line is the carb lever is the simplest to modify and is currently too long. Shorten the lever (it will increase force also) and give it a try.

I really dont mean to sound so snide.

I apologize for that.

I am a mechanical engineer and I would have calculated it out in advance. More than likely I would have been stuck with a certain starting point. Just as an example let's say a holley carb. So I would have called the engineering dept at holley and asked for the technical details such as spring rate and lever length. If they would not release info I would then measure for myself with a strain guage and a measured lever length.

Then I would determine how much force I would be willing to continually output with my hand, either by research or by measuring. Then use those two data points to calculate how long the lever on carb would have to be to match how force is required. Now with a lever length I would calculate the stroke required to move carb it's full range. Then with a stroke length I would calculate the radius of the hand throttle spool.

Then purchase or make a hand throttle that is that dimension. If the calculated spool size is beyond reasonable size I would then look into reducing/increasing the spring weight at the carb. If a spring weight is changed you would then start all over again and go back through the calcs again to double check.

I myself would have done this before purchasing the very first part.....then once figured I would buy the carb with the known spring rate, the throttle with the known spool diameter and then manufacture the carb lever length and the cable anchor bracket. Then assemble and most likely it works the first time with the desired stroke and force desired.

There are a few details left out....for instance....the carb stroke to the spool radius will probably not be a direct 1 to 1 ratio. So most likely the will be a ratio to apply to the force calculations. But assuming a 1 to 1 gets the starting point and you must figure from there.

And......yes......I have done this.....even on my own trike.

But like I said.....in the end of it all you already have certain parts that you want to make work. Bottom line is the carb lever is the simplest to modify and is currently too long. Shorten the lever (it will increase force also) and give it a try.

vwbug72501

700+ Posts

But like I said.....in the end of it all you already have certain parts that you want to make work. Bottom line is the carb lever is the simplest to modify and is currently too long. Shorten the lever (it will increase force also) and give it a try.

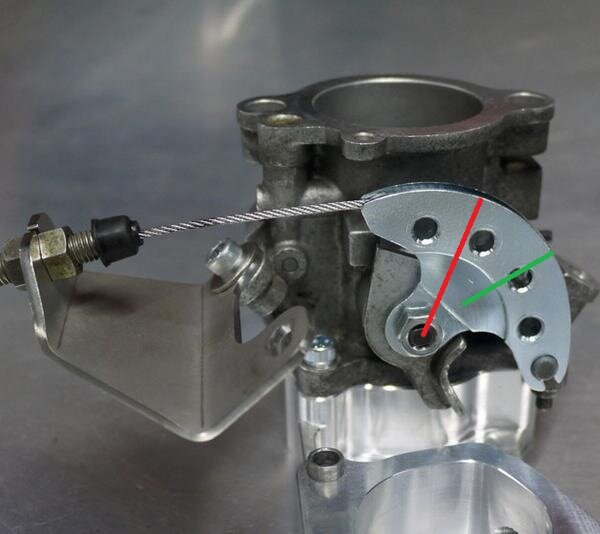

Picture version of Rex's reply:

Red line distance = more linear cable travel with less applied force.

Green line distance = less linear cable travel with more applied force.

The last picture is a bellcrank solution that will modify the different required linear travel lengths.

Hope this helps. Rex, correct me if I'm wrong.

DeathBySnuSnu

Old Redneck Motorhead

Yep.

And the throttle on the top pick is nice. I like the arc section a whole lot more than a simple lever.

The bell crank is a good idea. Actually it dont hafta be an L shape. And if you can not shorten/modify the lever on the carb....it would be a way to get the stroke up.

And the throttle on the top pick is nice. I like the arc section a whole lot more than a simple lever.

The bell crank is a good idea. Actually it dont hafta be an L shape. And if you can not shorten/modify the lever on the carb....it would be a way to get the stroke up.

there always has to be one smartass reply..

hold the both throttle and twist grip wide open and shorten cable accordingly

but seriously moving the cable end closer to the center will probably be the easiest... but if you have the round cable guide in the first photo you will need to remove it in that photo the distance from the pivot cant be changed

just in case the bell-crank didnt make sense .. hopefully this will help ..as mentioned some trial an error will be needed i think i would start with the hand throttle cable at least 1-1/2 inches from the pivot

hope that helps

hold the both throttle and twist grip wide open and shorten cable accordingly

but seriously moving the cable end closer to the center will probably be the easiest... but if you have the round cable guide in the first photo you will need to remove it in that photo the distance from the pivot cant be changed

just in case the bell-crank didnt make sense .. hopefully this will help ..as mentioned some trial an error will be needed i think i would start with the hand throttle cable at least 1-1/2 inches from the pivot

hope that helps

Attachments

LarryA

500+ Posts

an automobile carb will have pretty strong return spring, hence a lot of torque needed to hold throttle open at cruise. Does the harley have a 2 cable system so you can have a weaker return spring? Or, is this not a good idea to lessen spring pressure?:xzqxz:

an automobile carb will have pretty strong return spring, hence a lot of torque needed to hold throttle open at cruise. Does the harley have a 2 cable system so you can have a weaker return spring? Or, is this not a good idea to lessen spring pressure?:xzqxz:

while one previous post was talking about force..

the force isnt the issue its the amount of travel

LarryA

500+ Posts

LOL true, travel was the original issue....I'm thinking about 10 miles down the road when your wrist is getting tired and you are wishing for cruise control!

LOL true, travel was the original issue....I'm thinking about 10 miles down the road when your wrist is getting tired and you are wishing for cruise control!

ah changing the subject with a signal for the ole guy.... lol

dont tell anyone but i used to run a dead throttle.. 2 cables no spring.

.oh wait .. i still do.. hmmmm wonder why the call it dead..

i see no problem with a light spring long as it pulls the cable back

Thanks, that was a good read.

Another thing you can potentially look into is a 1/4 or 1/2 twist throttle; don't see them in the cruiser world but they are VERY common in the sport bike world & installed one on my old Busa after putting nitrous on it. The arch built into the twist throttle ramps up faster so that you are either 1/4 or 1/2 turn between closed & full throttle.

Personally speaking, once I got used to it & stopped doing accidental wheelies from stops it was one of the best "cheap mods" I ever did on my bike!

Just thinking outside the box for other options for you.

Personally speaking, once I got used to it & stopped doing accidental wheelies from stops it was one of the best "cheap mods" I ever did on my bike!

Just thinking outside the box for other options for you.

Trike Talk Community

Welcome to a community dedicated to the most diverse and fastest growing powersports segment, Motorcycle Trikes. Come join the discussion about the best makes and models, popular modifications and proven performance hacks, trike touring and travel, maintenance, meetups and more!

Register Already a member? LoginForum statistics