Zar

New member

hello Trike Talk people... first of all, thank you for letting me join this forum, I hope I will be able to be of help from time to time.

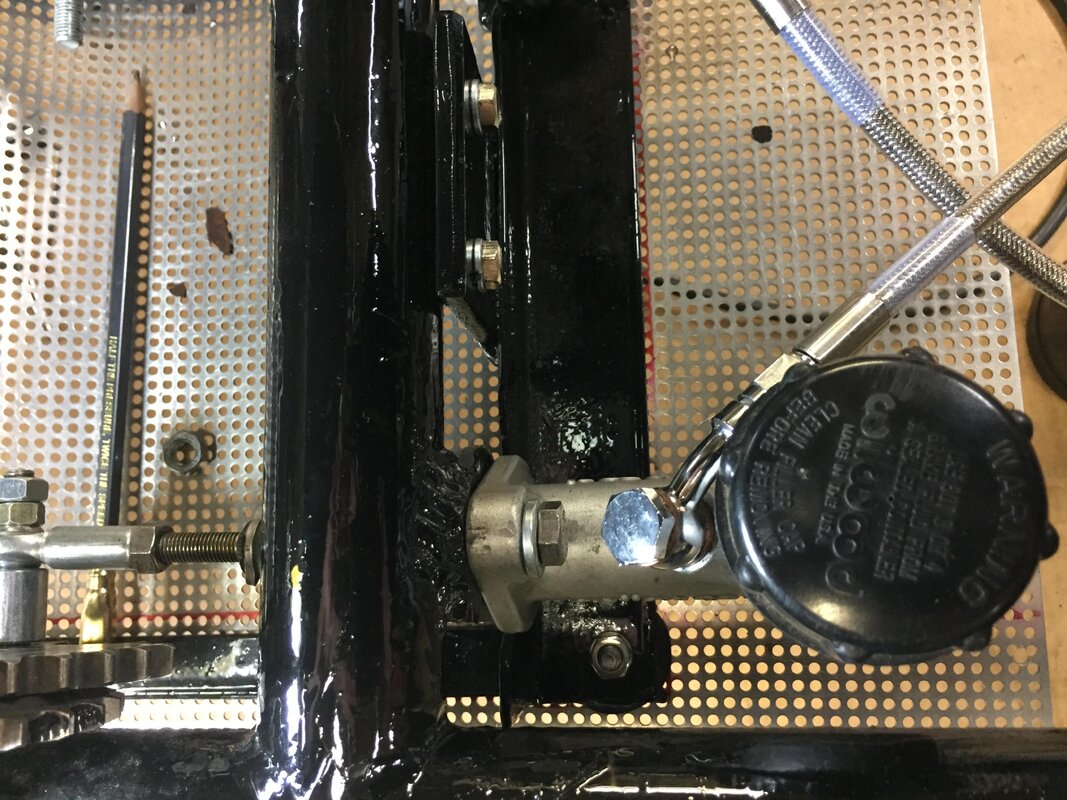

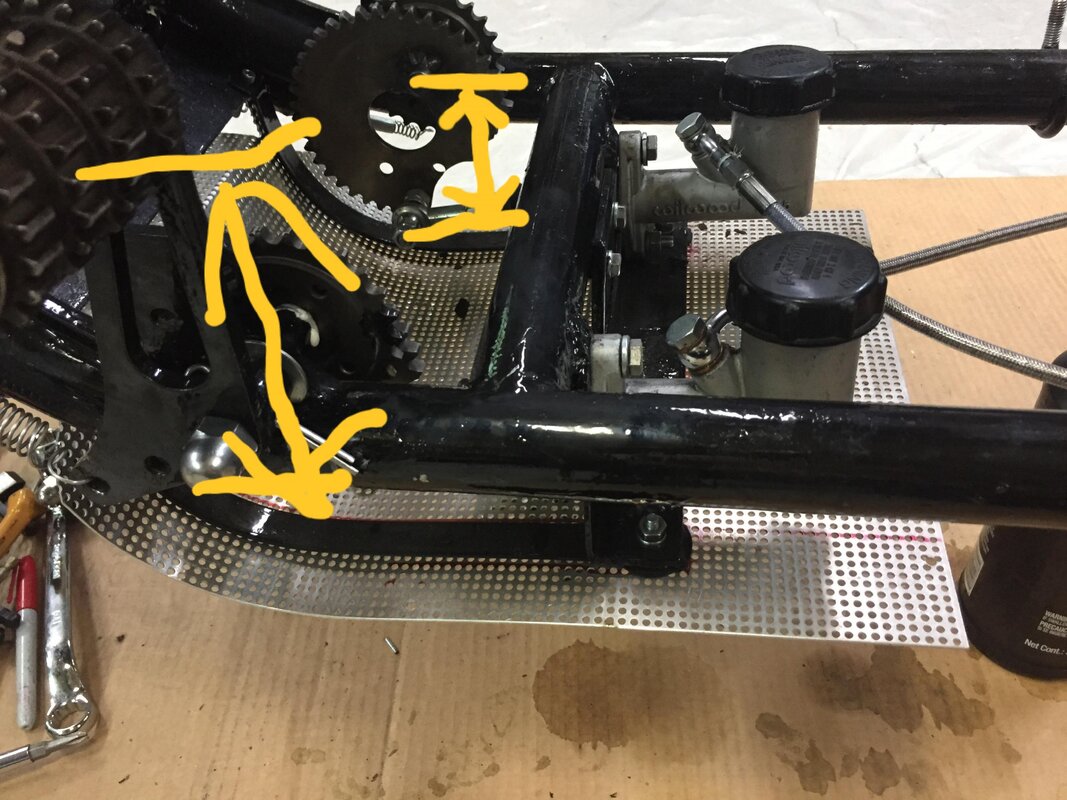

~ I am currently building a VW powered monster of a trike, and I'm in the semifinals, but the conversion to a hydraulic clutch system is where i hit the wall. I will try to describe what is going on to the best of my ability. I have a C&C slave cylinder properly installed, a 3/4"master cylinder as it is recommended, my flywheel, pressure plate and clutch pad are the correct type for my type 1 VW transmission and are new and in perfect and working condition, all the torque values are correct... I bled the system 3 times, and made sure there was no air in the system and at first everything looked to be working fine... but ones I got the engine fired up, the clutch would not disengage...

after a very complete Inspection, I found that the slave cylinder would only actuate up to the place where the throw bearing engages the pressure plate fingers, and stop. no mater the adjustments on the slave cylinder, it would only go that far... I took all the slack out of the slave cyl. push rods and the pedal was unmovable. I can disengage the clutch i by using a pry bar on the tranny throw arm... I also had the company that sold me the slave cylinder, send me a new one... but it made no difference.

Thanks,Cesar.

,

~ I am currently building a VW powered monster of a trike, and I'm in the semifinals, but the conversion to a hydraulic clutch system is where i hit the wall. I will try to describe what is going on to the best of my ability. I have a C&C slave cylinder properly installed, a 3/4"master cylinder as it is recommended, my flywheel, pressure plate and clutch pad are the correct type for my type 1 VW transmission and are new and in perfect and working condition, all the torque values are correct... I bled the system 3 times, and made sure there was no air in the system and at first everything looked to be working fine... but ones I got the engine fired up, the clutch would not disengage...

after a very complete Inspection, I found that the slave cylinder would only actuate up to the place where the throw bearing engages the pressure plate fingers, and stop. no mater the adjustments on the slave cylinder, it would only go that far... I took all the slack out of the slave cyl. push rods and the pedal was unmovable. I can disengage the clutch i by using a pry bar on the tranny throw arm... I also had the company that sold me the slave cylinder, send me a new one... but it made no difference.

Thanks,Cesar.

,