You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Volkswagen Kit Cars

- Thread starter DeathBySnuSnu

- Start date

Waiting on those suspension parts.

Did get the super low profile tires for the front.

The rear will be almost the same size as the old tires on the rims now.

I still hafta get another pan/chassis to cut up. I do have an older model one.....but it keeps raining and I caint get it pulled out of the trees and loaded up.

So the idea is red wheels. In my head wheels are supposed to be aluminum/silver. This is a new one for me here.

Only painted one.....just to make sure I like it.

I think I do.

Did get the super low profile tires for the front.

The rear will be almost the same size as the old tires on the rims now.

I still hafta get another pan/chassis to cut up. I do have an older model one.....but it keeps raining and I caint get it pulled out of the trees and loaded up.

So the idea is red wheels. In my head wheels are supposed to be aluminum/silver. This is a new one for me here.

Only painted one.....just to make sure I like it.

I think I do.

I got the other front wheel prepped and painted. Now to wait a day or two and mount the other front tire with the motorcycle tire spoons.

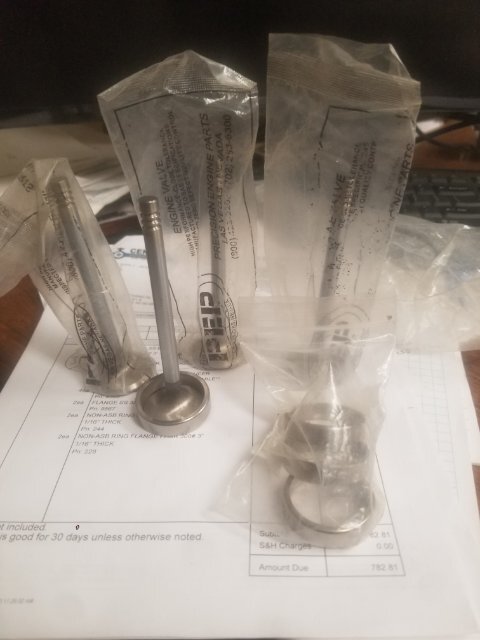

The front end big parts came in today.

2-1/2" drop spindles.

Rotors and calipers.

Bearings and seals.

Camber adjusters and brake hoses.

I know.....no lug bolt holes.

I need a pattern they are not available in.

So I will put my own holes in.

5 on 100mm circle and M12 x 1.5 metric stud and some odd nuts these wheels take.

Just waiting on some money to spend on the lugs.

The front end big parts came in today.

2-1/2" drop spindles.

Rotors and calipers.

Bearings and seals.

Camber adjusters and brake hoses.

I know.....no lug bolt holes.

I need a pattern they are not available in.

So I will put my own holes in.

5 on 100mm circle and M12 x 1.5 metric stud and some odd nuts these wheels take.

Just waiting on some money to spend on the lugs.

So the plan on the chassis is to have it as low as what is reasonable. I do not want it to drag the ground. I may have to go around bigger obstacles like larger speed bumps.

The spindles lower the front 2-1/2" and I have to go this way because I can not move the front torsion beam. I will remove the front springs and set the suspension down on the bottom out stops. With the spindles and short tires I should be quite low at full bottom. I hope my measurements hold up and the chassis is where I want it on the front. Then if it is I will lower the floor boards to get a bit more leg room.

Your butt goes in the low spot the battery was originally mounted in. The top of the tunnel is about 6 inches from the dash. I will probably cut the whole dash area out of it and only use a pod console with switches. It is incredibly hard for an old man to get into....lol.

So if that works out....

The rear will not be squatted down to match like the lowered beetles do. I will cut the entire rear torsion tube and shock towers out of the chassis horns and raise/move it to match height the front.

After all that is done at full bottom out....I will the lift it up and install the springs.....tentatively 3 inches off bottom. I should be in the sweet spot of the suspension travel and close to geometry. I have the offset bushings to get the front end aligned. I do not know yet if I will have to move the inside anchor points for the rear arms to get the alignment I want.

The spindles lower the front 2-1/2" and I have to go this way because I can not move the front torsion beam. I will remove the front springs and set the suspension down on the bottom out stops. With the spindles and short tires I should be quite low at full bottom. I hope my measurements hold up and the chassis is where I want it on the front. Then if it is I will lower the floor boards to get a bit more leg room.

Your butt goes in the low spot the battery was originally mounted in. The top of the tunnel is about 6 inches from the dash. I will probably cut the whole dash area out of it and only use a pod console with switches. It is incredibly hard for an old man to get into....lol.

So if that works out....

The rear will not be squatted down to match like the lowered beetles do. I will cut the entire rear torsion tube and shock towers out of the chassis horns and raise/move it to match height the front.

After all that is done at full bottom out....I will the lift it up and install the springs.....tentatively 3 inches off bottom. I should be in the sweet spot of the suspension travel and close to geometry. I have the offset bushings to get the front end aligned. I do not know yet if I will have to move the inside anchor points for the rear arms to get the alignment I want.

Don't take this the wrong way Rex, but that sounds like a lot of work to get the lowrider look?

A complete re~engineering of the stock beetle suspension and chassis is, as you're aware, quite an undertaking...

Why not simply use the lower than stock front spindles you now have, and air bag it to accomplish the rear lowering?

A complete re~engineering of the stock beetle suspension and chassis is, as you're aware, quite an undertaking...

Why not simply use the lower than stock front spindles you now have, and air bag it to accomplish the rear lowering?

Ok..

The objective is NOT the low rider look.

The objective is the low sports car/ racer look.

The front spindles lower the front without changing suspension travel, trailing arm angles, or the overall geometry of the front. An increase in scrub radius, but that is gonna happen with wider wheels anyway. Just add the offset bushings so you can move the camber from a couple degrees positive to a couple degrees negative and possibly a heavier sway bay.......and you have hard cornering geometry.

So for the back end......yes it is "normal" to just squat the rear suspension down, even remove or use short rubber bottom out stops. But it kills the handling. You would be much better off just leaving it near stock.....just letting down a spline tooth or so until you get to one degree negative camber.

Hard racers drop the back down with lots of bracketry. Engine and trans raise, offset trailing arms....all kinds of stuff to avoid the squatted low rider handling.

I have no body limits....I am willing to cut the body or whatever. So the current plan is to move the entire rear suspension and its geometry to where I want it to be. Thus avoiding the handling complications involved in squatting it down.

It may not actually work out that way.......but the math fits.

The objective is NOT the low rider look.

The objective is the low sports car/ racer look.

The front spindles lower the front without changing suspension travel, trailing arm angles, or the overall geometry of the front. An increase in scrub radius, but that is gonna happen with wider wheels anyway. Just add the offset bushings so you can move the camber from a couple degrees positive to a couple degrees negative and possibly a heavier sway bay.......and you have hard cornering geometry.

So for the back end......yes it is "normal" to just squat the rear suspension down, even remove or use short rubber bottom out stops. But it kills the handling. You would be much better off just leaving it near stock.....just letting down a spline tooth or so until you get to one degree negative camber.

Hard racers drop the back down with lots of bracketry. Engine and trans raise, offset trailing arms....all kinds of stuff to avoid the squatted low rider handling.

I have no body limits....I am willing to cut the body or whatever. So the current plan is to move the entire rear suspension and its geometry to where I want it to be. Thus avoiding the handling complications involved in squatting it down.

It may not actually work out that way.......but the math fits.

Well.....I did not take any pictures.

I was off work and it did not rain this Saturday. So the little car got tore down. Body is off. Quite a few bits and pieces went in the dumpster. Other things were surprisingly whole and/or rebuildable. Such as the master cylinder was still full of fluid and appeared almost serviceable.

The engine is not stuck, probably some stuck valves, but it is not rusted solid as expected. So I should have a lot of usable parts inside.

I was off work and it did not rain this Saturday. So the little car got tore down. Body is off. Quite a few bits and pieces went in the dumpster. Other things were surprisingly whole and/or rebuildable. Such as the master cylinder was still full of fluid and appeared almost serviceable.

The engine is not stuck, probably some stuck valves, but it is not rusted solid as expected. So I should have a lot of usable parts inside.

While I was disassembling I did hold the wheels up to the hubs.

Of course I had done a lot of measuring beforehand......but they are a tight fit as expected. The drop spindles and disc brakes will be a bit wider.....and if that holds true then the front wheels may just ever so barely clear.

The back end though.....cleared the arms and spring plates better than expected.....but did not clear the bump stop tab by the upper shock mount. So I went down one size tire for the rear and i might have to use a spacer around 1/4" . Or i might modify the stop tab.

So......tires are picked out for the rear now.

Of course I had done a lot of measuring beforehand......but they are a tight fit as expected. The drop spindles and disc brakes will be a bit wider.....and if that holds true then the front wheels may just ever so barely clear.

The back end though.....cleared the arms and spring plates better than expected.....but did not clear the bump stop tab by the upper shock mount. So I went down one size tire for the rear and i might have to use a spacer around 1/4" . Or i might modify the stop tab.

So......tires are picked out for the rear now.

Well.....

It is looking more and more like this thing is gonna be turned mid engine.

Still figuring on it. I do have a set of 5 inch a side shorter springs left (still in the car) from narrowing the rear of a bug to fit big tires under the fenders.

If I were to use the shortness to make a gap in the middle of the torsion tube.......stick the case in the gap.

In the end would be something like this

It is looking more and more like this thing is gonna be turned mid engine.

Still figuring on it. I do have a set of 5 inch a side shorter springs left (still in the car) from narrowing the rear of a bug to fit big tires under the fenders.

If I were to use the shortness to make a gap in the middle of the torsion tube.......stick the case in the gap.

In the end would be something like this

That would be kewl ... I had a mid engine (sorta) 67 MGBGT, salvage title, when I was in high school ... built it in auto shop with the help of a few of my friends ... 283 mounted where the back seat was ... LOL ... was so hot in the car you could only drive it late fall to early spring in Massachusetts ... who knew a small block chevy generated that kind of heat ... LOL ... got lots of lookie loos though ... finally took the souped up engine out and sent the body to the scrap yard ... wishing now I'd of just done the body work and kept it

Rmitchell55

850+ Posts

Had a shipmate that had a "65 Corvair with a '67 Vette 327 in the back seat. Was built by a group at Hobby shop at Travis AFB while they were going to Nuc School at Mare Island back in late 60's.

Once upon a time ago.....I was traveling through Florida and saw a guy in a parking lot that I had to turn around and see.

A Bradley gt2 (like that basement hanger I posted before) they are on a full length pan and already have a lot of unused room where the back seat used to be. So this one had a toronado transaxle and a hot rodded 455 mid engine. Pulleys were right at the seats and the tunnel ran and two fours were stuck out the roof.

I dont know how hot is was inside.....but he was driving it in summer.

So as for my project..... I am wanting more of a 50-60's euro racer. A lot more of the le-mans and less of the drag strip. I may have ruined that with the 80's jap wheels....but I like them anyway.

That flip backwards rear hood and an engine that looks like it is supposed to be in the car......but no one has ever heard of.

A Bradley gt2 (like that basement hanger I posted before) they are on a full length pan and already have a lot of unused room where the back seat used to be. So this one had a toronado transaxle and a hot rodded 455 mid engine. Pulleys were right at the seats and the tunnel ran and two fours were stuck out the roof.

I dont know how hot is was inside.....but he was driving it in summer.

So as for my project..... I am wanting more of a 50-60's euro racer. A lot more of the le-mans and less of the drag strip. I may have ruined that with the 80's jap wheels....but I like them anyway.

That flip backwards rear hood and an engine that looks like it is supposed to be in the car......but no one has ever heard of.

Worked with it some today.....ever so slowly it seems.

Still working the wheels into shape. I saw where one of the rear wheels had a big pile of sticky back weights on it........and thought I better check it to make sure it ain't bent. Well it was not bent but was wayyyyy heavy to one side. Spent hours grinding on it to get it close to balance. Used one of the new spindles and the drilled rotor to mount and hand spun and let the heavy side settle to the bottom. Then grind some more. I think I got it close enough that dyna beads will work.

Then I went back and checked the two I had already painted and mounted tires on. I had no reason to suspect them.....and there was nothing abnormal about them.

Then checked the other rear wheel I have not worked with yet....also no reason to suspect it.....but it was bent. Not horribly....and only on the inside edge.

Man what an awakening as to how flexible an aluminum wheels is. When I did the murdercycle wheels and had them in the lathe chuck they were flexible.....I could just lightly squeeze them.....that is why they did not get more machine work done to them to dress them up. So fast forward to today and these extra lightweight racing wheels. Talk about flexible.....just squeeze them all over the place....but they just spring back like a balloon. I had to squeeze and stretch it to where I wanted it and heat/anneal it to get it to stay. It took quite a few trys......but I got it true and round. But that burned up several hours also.

I did get one wheel sanded in, primed and painted. Put on a spindle and rotor to the beam to check back spacing and interference. Painted the showing side of the rotors red as I am reasonably happy with the fit (no additional wheel spacers).

I wanted to get the beam bolted onto the frame head and a few other frame/chassis measurements and plans made.....but did not make it that far.

I did get the old chassis inside and removed a few part and the rear drums. Then at least started towards plans of the mid engine. It looks like I will have to lengthen it at least 8 inches....maybe more to be able to change the belt.

Still working the wheels into shape. I saw where one of the rear wheels had a big pile of sticky back weights on it........and thought I better check it to make sure it ain't bent. Well it was not bent but was wayyyyy heavy to one side. Spent hours grinding on it to get it close to balance. Used one of the new spindles and the drilled rotor to mount and hand spun and let the heavy side settle to the bottom. Then grind some more. I think I got it close enough that dyna beads will work.

Then I went back and checked the two I had already painted and mounted tires on. I had no reason to suspect them.....and there was nothing abnormal about them.

Then checked the other rear wheel I have not worked with yet....also no reason to suspect it.....but it was bent. Not horribly....and only on the inside edge.

Man what an awakening as to how flexible an aluminum wheels is. When I did the murdercycle wheels and had them in the lathe chuck they were flexible.....I could just lightly squeeze them.....that is why they did not get more machine work done to them to dress them up. So fast forward to today and these extra lightweight racing wheels. Talk about flexible.....just squeeze them all over the place....but they just spring back like a balloon. I had to squeeze and stretch it to where I wanted it and heat/anneal it to get it to stay. It took quite a few trys......but I got it true and round. But that burned up several hours also.

I did get one wheel sanded in, primed and painted. Put on a spindle and rotor to the beam to check back spacing and interference. Painted the showing side of the rotors red as I am reasonably happy with the fit (no additional wheel spacers).

I wanted to get the beam bolted onto the frame head and a few other frame/chassis measurements and plans made.....but did not make it that far.

I did get the old chassis inside and removed a few part and the rear drums. Then at least started towards plans of the mid engine. It looks like I will have to lengthen it at least 8 inches....maybe more to be able to change the belt.

Well.....not a lot of progress made.

But a lot of plan changes.

It is definitely going to be mid engine. Might be the vw trans.....or I have an eye on a 914 Porsche trans.

But it definitely will not have the air cooled vw motor. I done went and got an old Mazda klze. A little 2.5 liter v6. Big bore, short stroke, double overhead cam, hemi headed, 8000rpm in stock trim screamer. Not real high hp....under 200 and low torque. A heavily modded vw trans could handle it.

So the plan it independent throttle bodies and a computer.

But a lot of plan changes.

It is definitely going to be mid engine. Might be the vw trans.....or I have an eye on a 914 Porsche trans.

But it definitely will not have the air cooled vw motor. I done went and got an old Mazda klze. A little 2.5 liter v6. Big bore, short stroke, double overhead cam, hemi headed, 8000rpm in stock trim screamer. Not real high hp....under 200 and low torque. A heavily modded vw trans could handle it.

So the plan it independent throttle bodies and a computer.

Making parts.

So here is the beginning of the elephant ears.

Sorta.

Elephant ears are a drag racing engine mount that typically are a plate on the pulley end of a v8 sandwiched between the timing cover and the block.

As the engine I picked has no motor mount point on the sides of it.....because it was sideways in a front wheel drive car.....I have to create mount points.

So here is the idea....ears at bell housing end incorporated into the adapter.

Mazda klze all aluminum double overhead cam hemi chambered 4 valve per cylinder 2.5 liter V6

To

Porsche 901 reverse rotation side shifter transaxle from a 914. (Same axle flanges as beetle).

Elephant ear motor mount.

Will be rubber mounted with suspension bushings at the ears and the single original mount at the pulley end of the engine.

So here is the beginning of the elephant ears.

Sorta.

Elephant ears are a drag racing engine mount that typically are a plate on the pulley end of a v8 sandwiched between the timing cover and the block.

As the engine I picked has no motor mount point on the sides of it.....because it was sideways in a front wheel drive car.....I have to create mount points.

So here is the idea....ears at bell housing end incorporated into the adapter.

Mazda klze all aluminum double overhead cam hemi chambered 4 valve per cylinder 2.5 liter V6

To

Porsche 901 reverse rotation side shifter transaxle from a 914. (Same axle flanges as beetle).

Elephant ear motor mount.

Will be rubber mounted with suspension bushings at the ears and the single original mount at the pulley end of the engine.

Similar threads

- Replies

- 6

- Views

- 15,734

- Replies

- 4

- Views

- 13,763

- Replies

- 8

- Views

- 391

- Replies

- 2

- Views

- 154

- Replies

- 6

- Views

- 277

- Replies

- 13

- Views

- 6,007

- Replies

- 12

- Views

- 3,365